Hi guys and gals. I have someone asking me how the front end of an engine goes together. Since I don't know how to attach images for a PM, I'm going to use this post to show him what he needs to know and any of you newbies can also learn from this.

First I'm going to assume that you have the front of the engine torn down.

Now The first thing that I look for are the two oil galley plugs that go into the holes behind the camshaft thrust plate. Some people have argued that you don't need these and that some engines came out of the factory without them, but in my experience, I needed them. I pulled an engine out 5 times for low oil pressure before finding out that the machine shop left these two plugs out. I could not get more than 30 psi cold start and less than 20 when warm. After that experience, I always check for these. If you don't want to run them, that's your choice, just don't come crying later if you have low oil pressure.

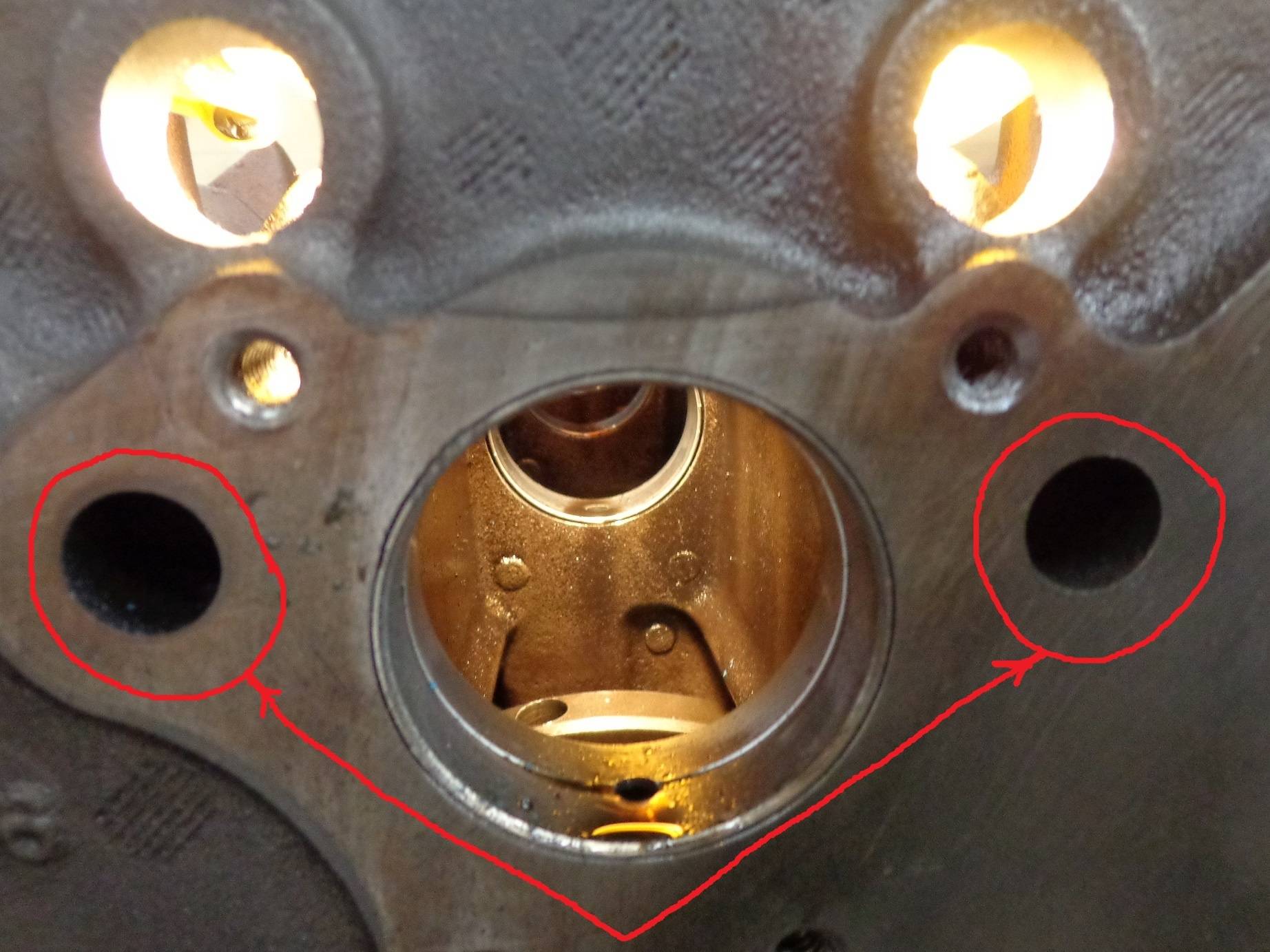

Here is a picture of the two holes with the galley plugs circled:

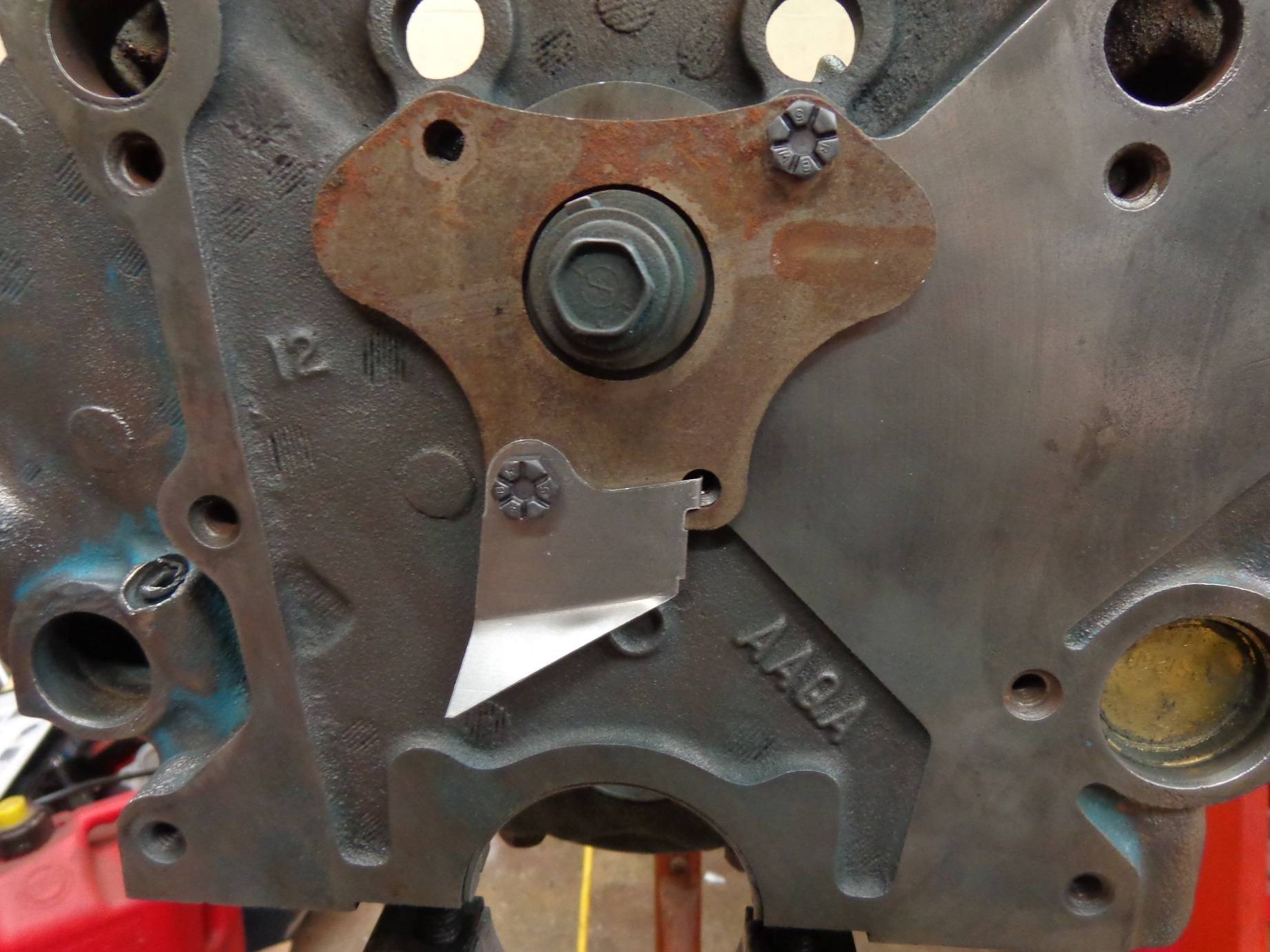

This picture I have circled the top left bolt hole for the camshaft thrust plate. Behind the wall, I have a trouble light showing you that the hole goes all the way through to the lifter valley. This hole is the only one that goes through to the lifter valley and is used to supply oil to the timing chain. There is a special camshaft thrust plate bolt with a hole drilled through the center of it that is made to go in here and supply oil to the timing chain.

I have seen three different configurations from the factory in this area. One of them doesn't use the "drip tab", and one does. You can use the other three bolts without the center hole drilled for the other holes, and just leave this one open.

Second, I have seen the timing tab used, and then you should use the special bolt with the hole drilled through it. I like the timing tab as I feel that it directs the oil better to drip directly onto the chain, so that is how I like to build mine. However, it uses an anti-rotational tab that goes into the bottom (driver's side) bolt hole and does't allow for a bolt to go in there. That is why I use the bolt with the oil hole, as I would rather have 3 bolts holding the plate in place than only just 2.

Here the bolt hole is circled:

These pictures came from a block that I tore down, and they did not have the oil galley plugs in this block that I mentioned for the first picture. That's why I circled them in red here.

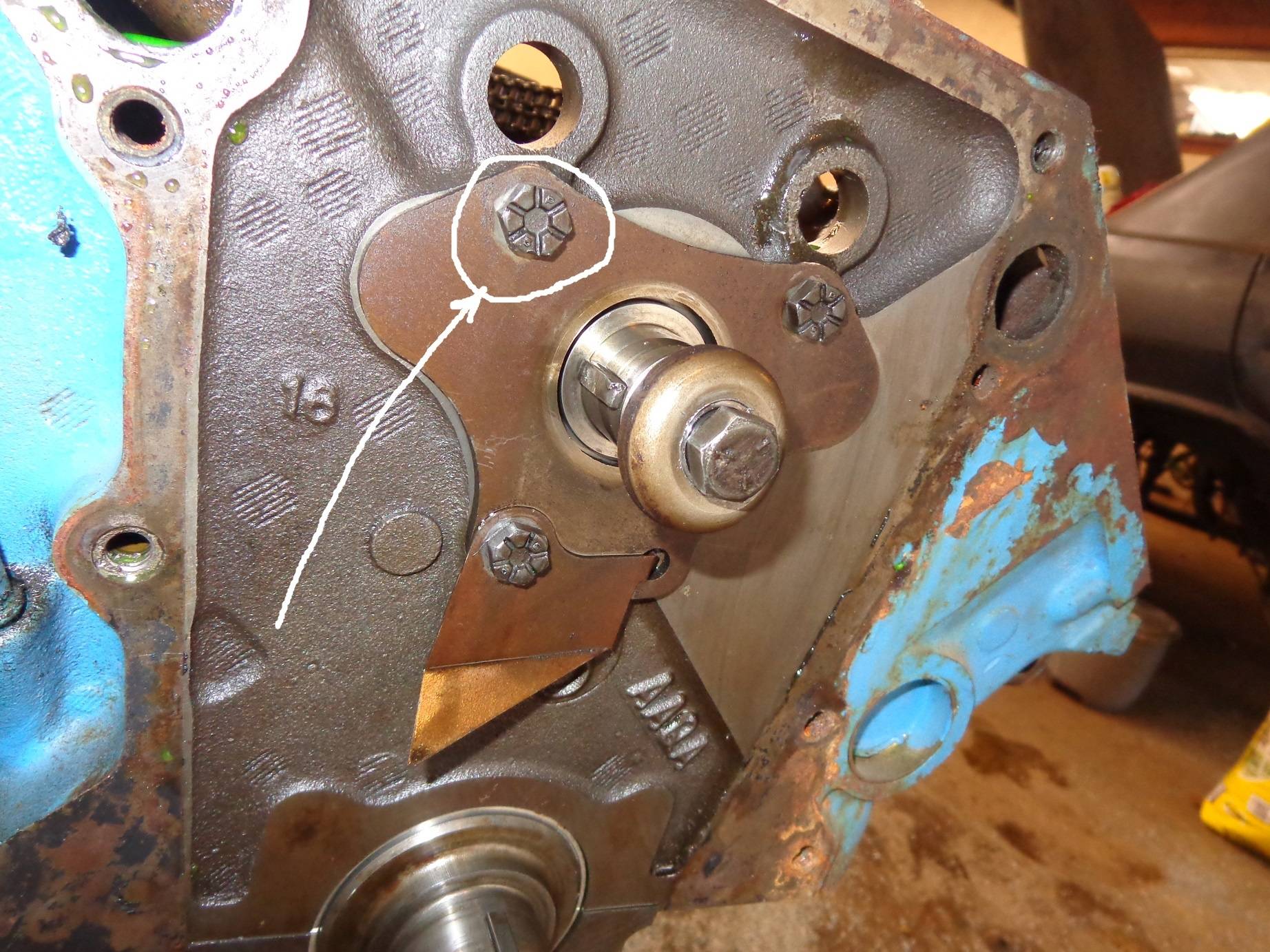

Here is a picture of the front of the camshaft thrust plate, this side faces away from the block:

Here is a picture of the back of the camshaft thrust plate, this faces toward the block:

Here's a picture of the camshaft thrust plate and timing tab assembled, but I have not put in the special bolt with the oil hole yet:

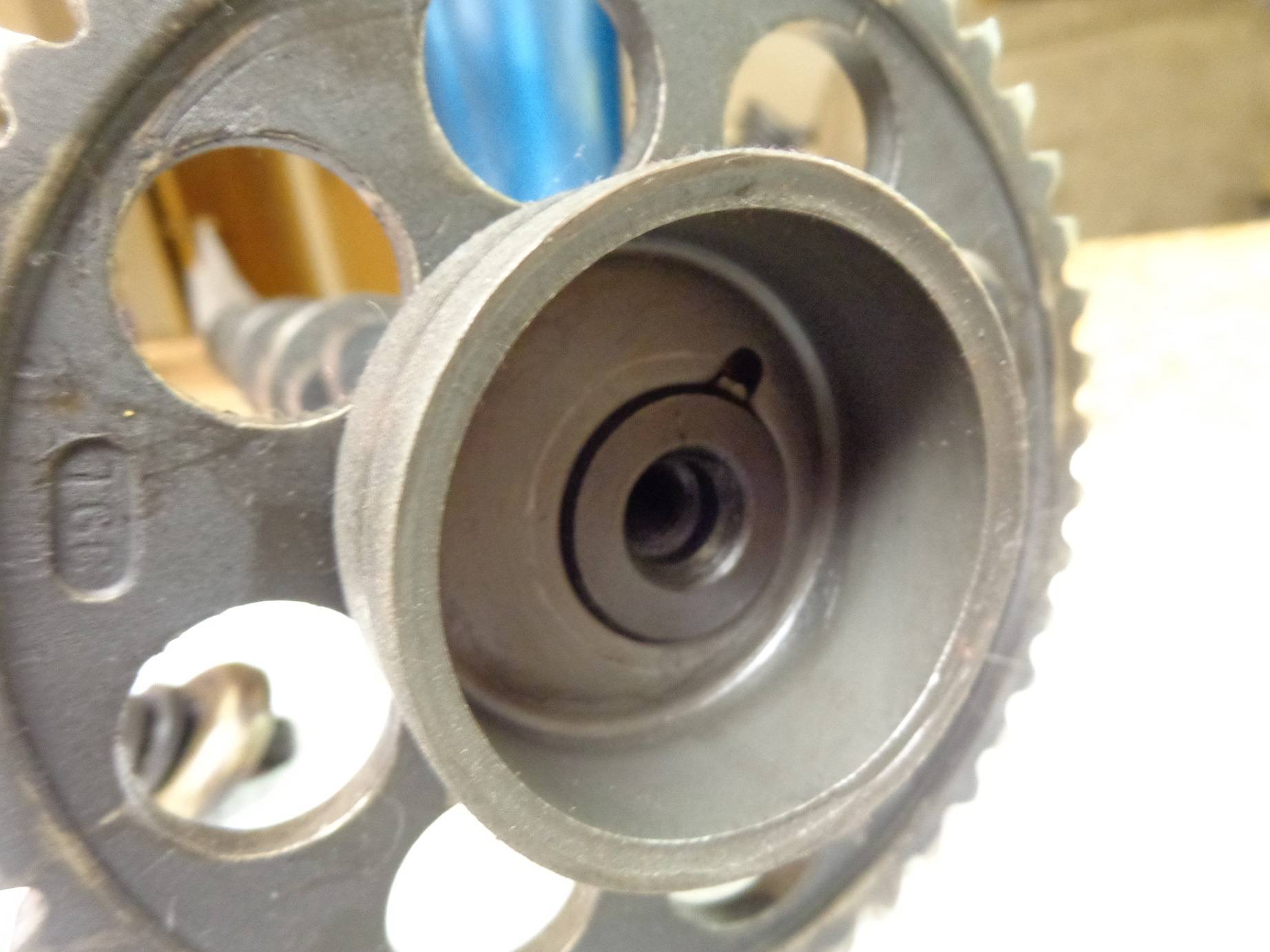

Here's a picture of the proper bolt with the oil hole drilled in it:

Here's a picture of that engine that I tore down that had the wrong bolt in there without the oil hole drilled. This won't let the oil get to the timing chain properly:

KEEP'EM Coming!!!

Treblig

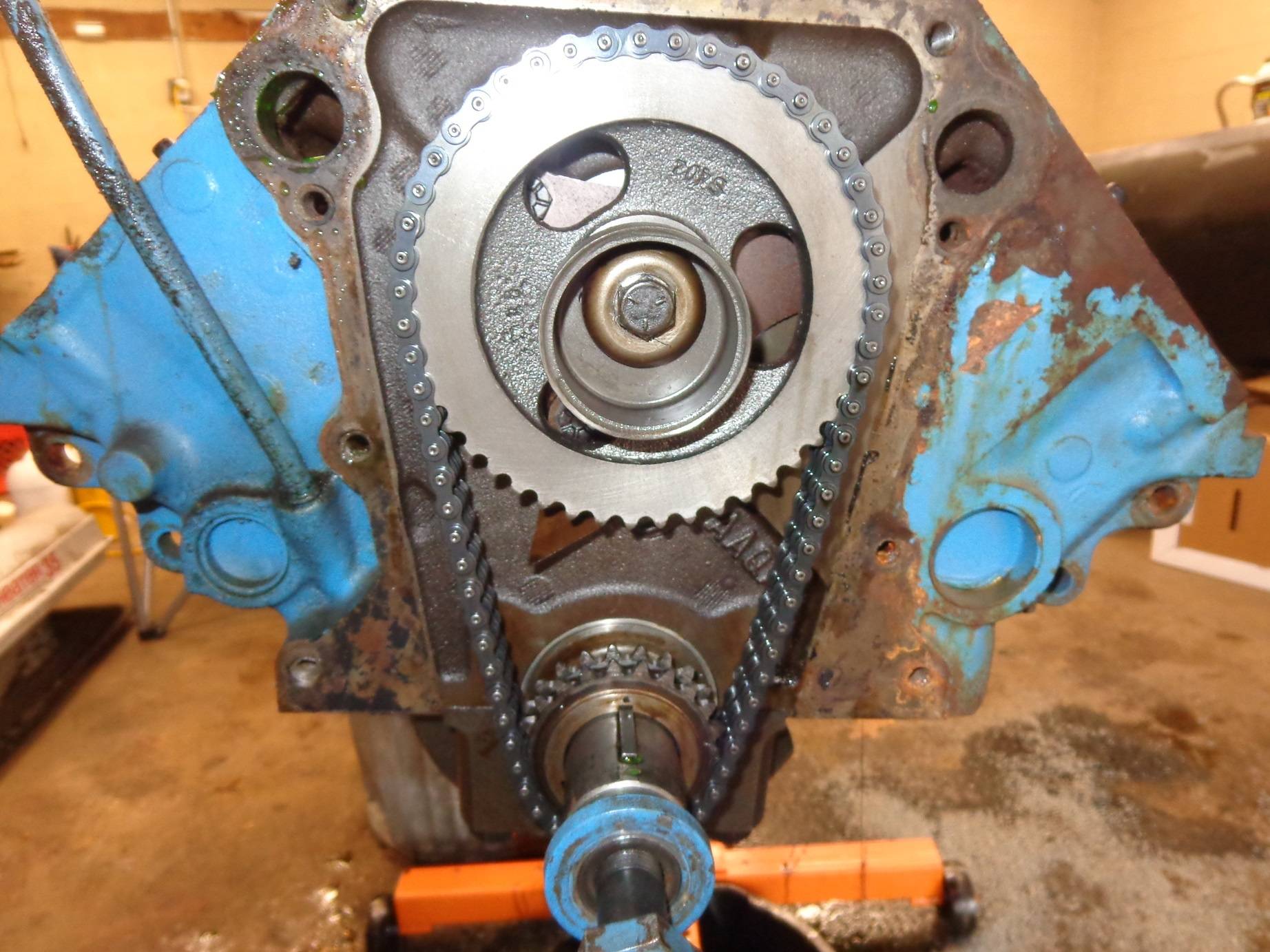

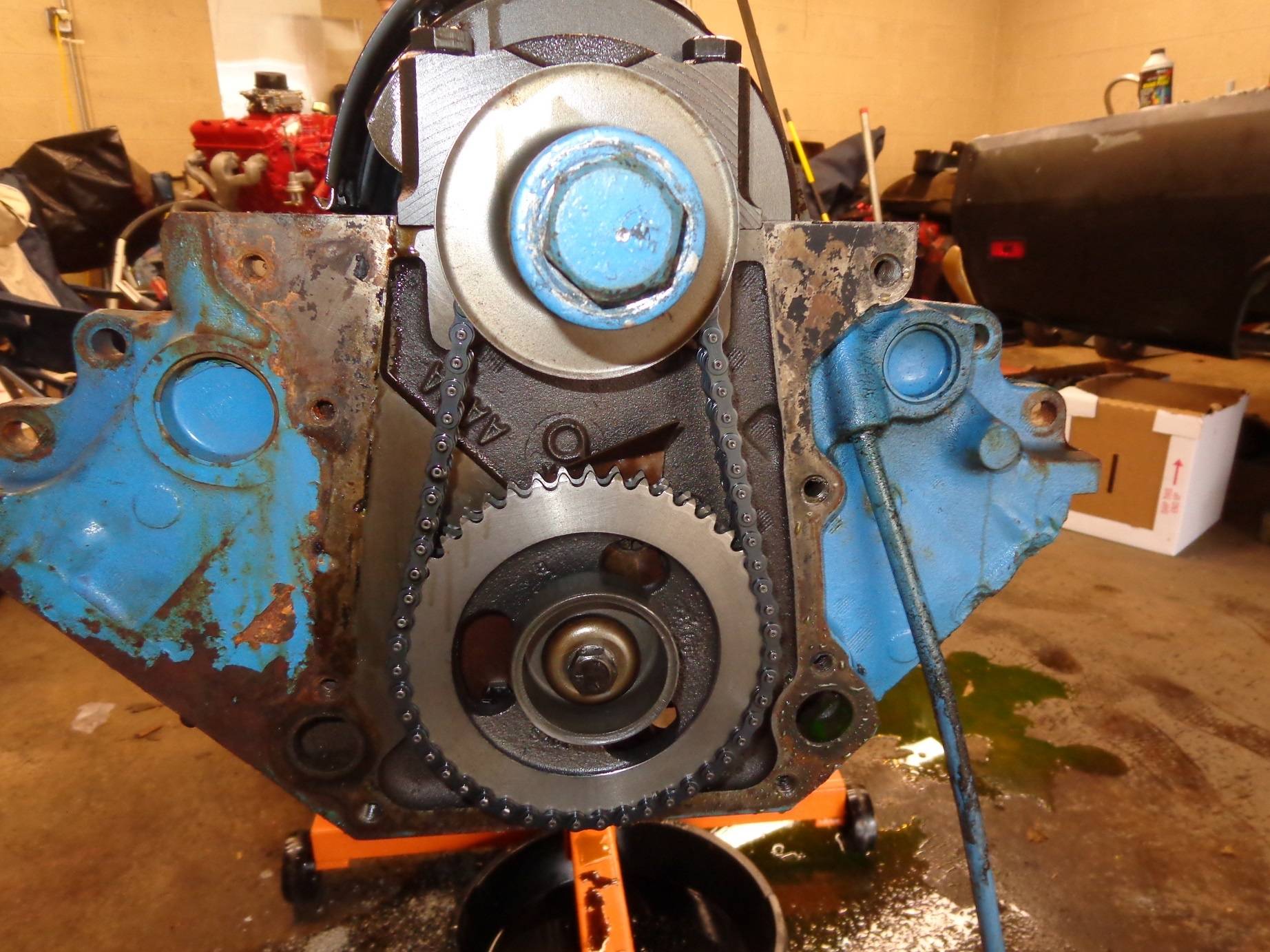

Here's a shot showing all of the pieces go together for the timing gear:

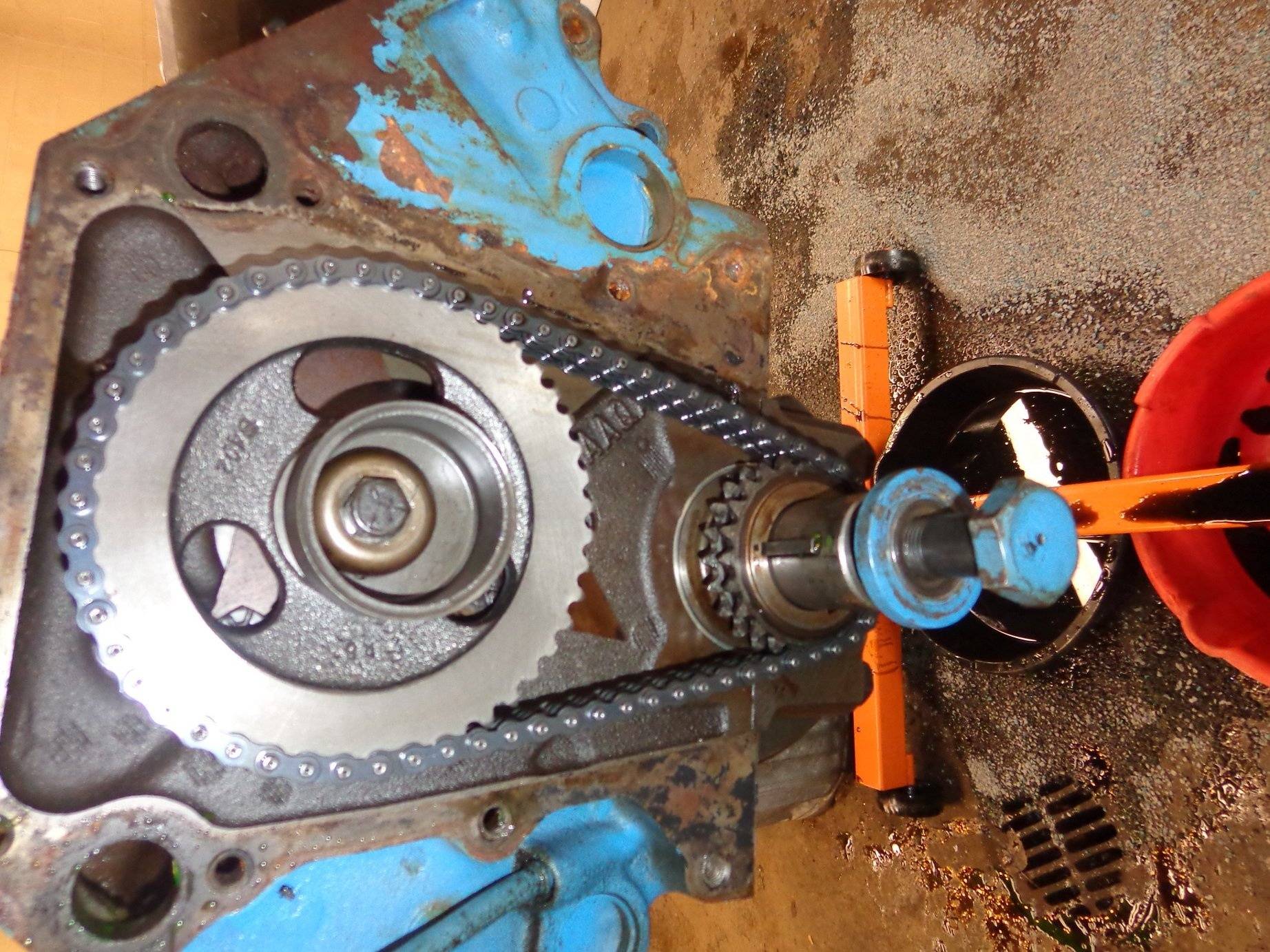

Here is the timing gear all the way down, showing how much keyway sticks out:

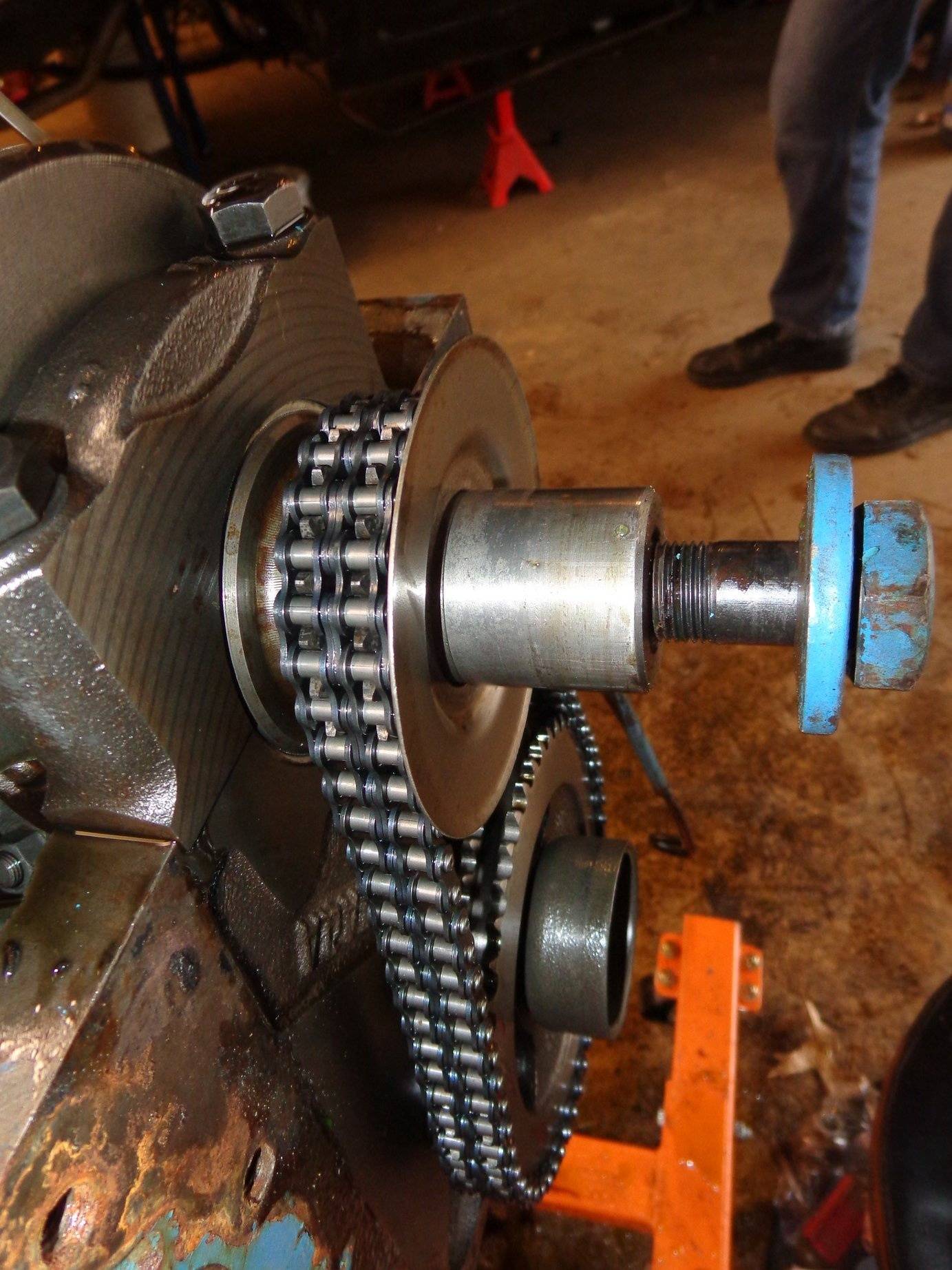

Here is a side view with the bolt and washer shown:

Now here are some shots with the fuel pump eccentric showing how that fits:

A closer shot:

One from a little farther away:

Here it is with all of the parts together and the bolt in place:

Note: The small camshaft thrust plate bolts should all be torqued to 210 INCH-POUNDS (not FOOT pounds) --> there was a mis-print on this torque in some service manuals, it did not specify "inch" pounds.

The large bolt that holds the timing chain gear and fuel pump eccentric on should be torqued to 35 FOOT-POUNDS.

When installing the timing chain, I like to get the gears set before I install them and then turn the cam to line up with how the timing chain and gears are set. You should line up the mark on the cam gear to be at 6 o'clock, and the timing mark for the crankshaft at 12 o'clock. You also can put the cam mark at 12 o'clock and the crank gear at 12 o'clock, it will just be on the intake stroke instead of the compression stroke, but you can account for that when you install the distributor.

Here is a picture of the BACK of the oil slinger. It goes on the crankshaftafter the crankshaft timing gear. It fits loosely (but is held in place when the vibration damper is installed). Notice that the "flare" on the outside, this goes outward toward the front of the car, away from the gear (if you put it toward the gear, the slinger will get all chewed up).

Here is a shot of the front of the oil slinger. Notice the flare coming outward. This is the side that goes away from the timing gears when installed:

Here's a shot of the front of the engine all put together.

Here's a closer shot:

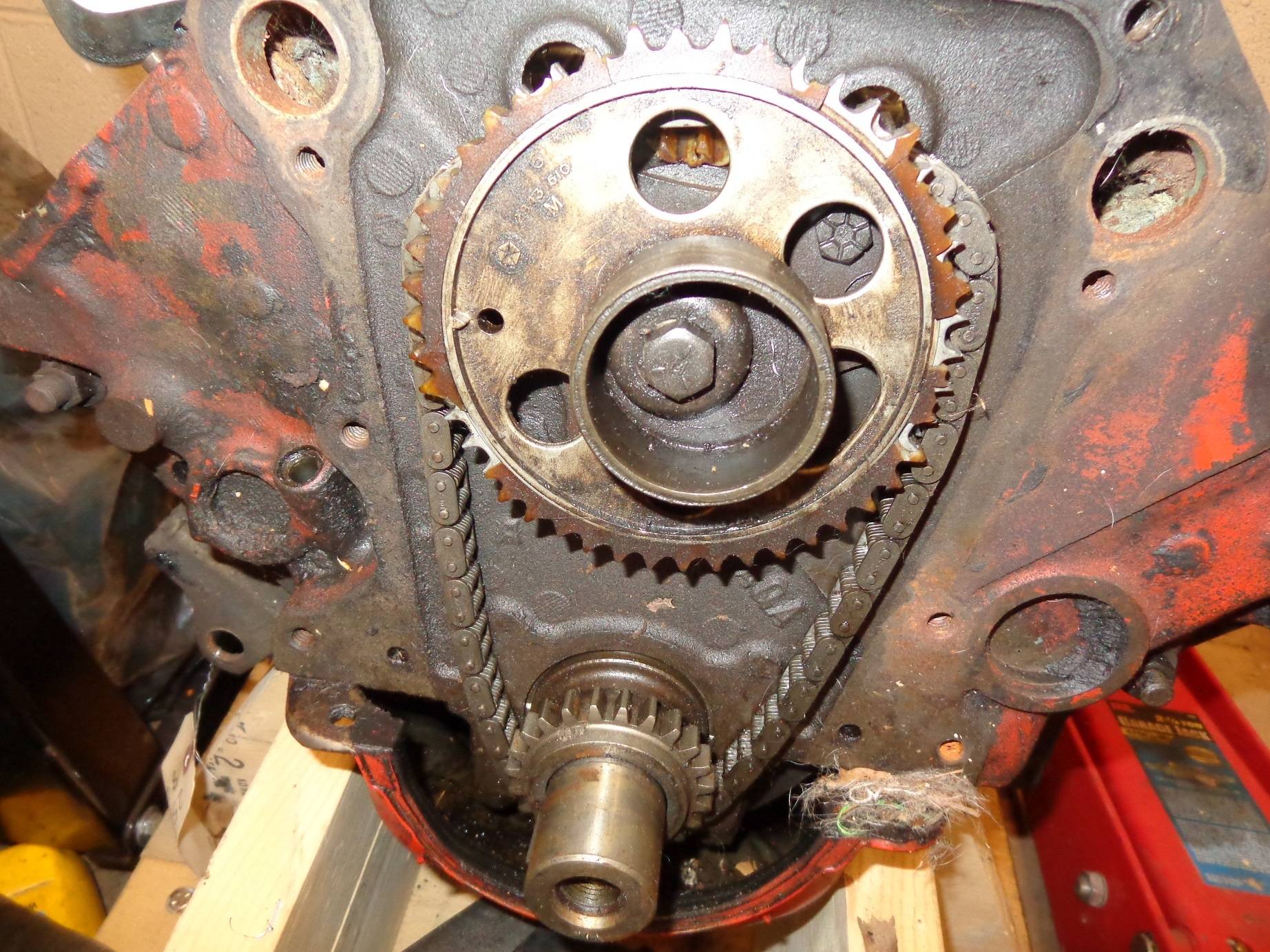

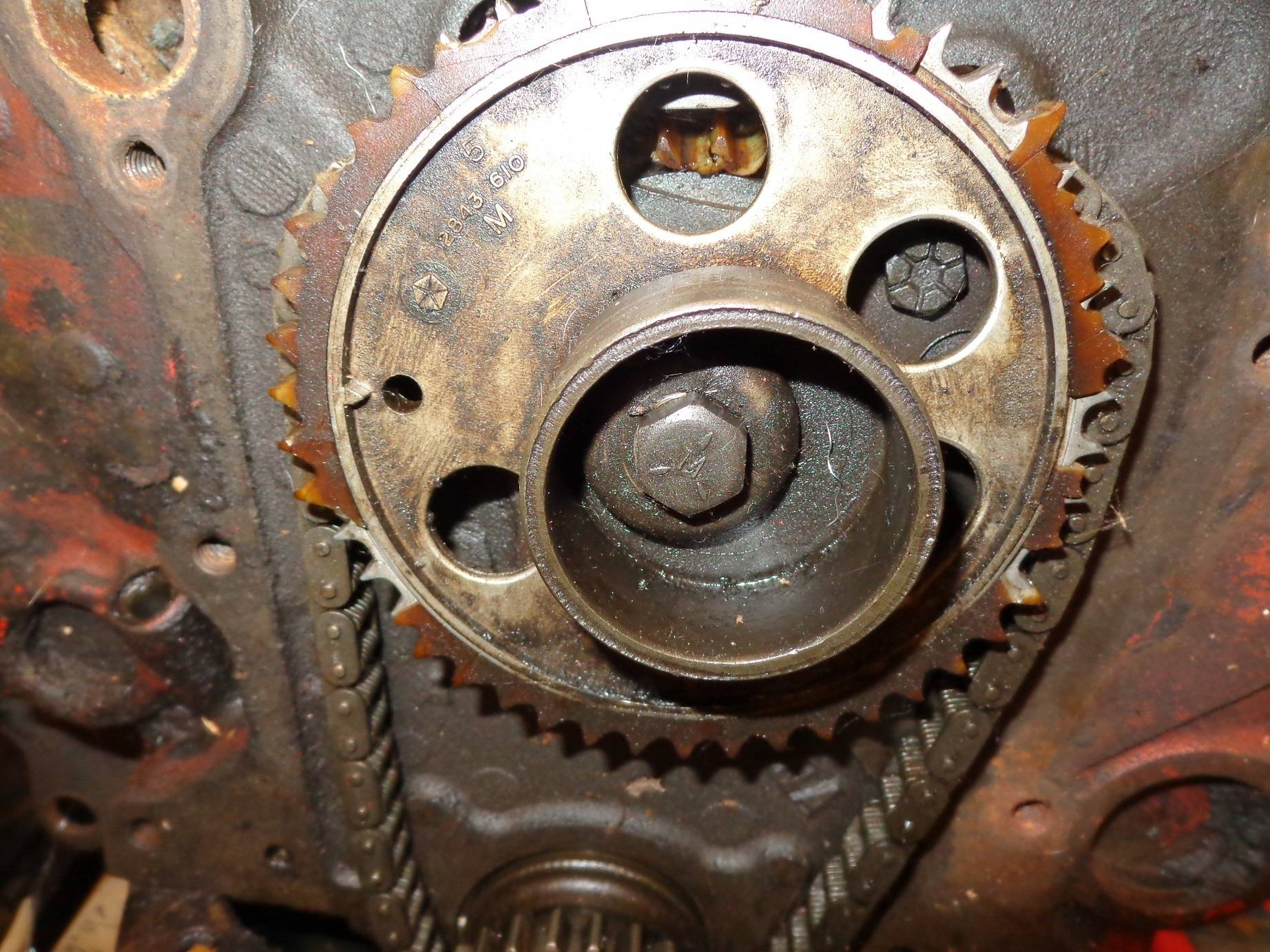

Here are two shots from an old worn engine. This is an old 318 with the old single chain and nylon coated gear. Notice how some of the nylonplastic has chipped off of the gears and the chain is so stretched, that it literally slipped off. This is why I run only double rollers and usually upgrade to the true roller double roller chains:

Another shot:

Now you can install the timing chain cover and water pump.

I just noticed that there were no pictures with the oil slinger installed. Here's how it goes:

First I'm going to assume that you have the front of the engine torn down.

Now The first thing that I look for are the two oil galley plugs that go into the holes behind the camshaft thrust plate. Some people have argued that you don't need these and that some engines came out of the factory without them, but in my experience, I needed them. I pulled an engine out 5 times for low oil pressure before finding out that the machine shop left these two plugs out. I could not get more than 30 psi cold start and less than 20 when warm. After that experience, I always check for these. If you don't want to run them, that's your choice, just don't come crying later if you have low oil pressure.

Here is a picture of the two holes with the galley plugs circled:

This picture I have circled the top left bolt hole for the camshaft thrust plate. Behind the wall, I have a trouble light showing you that the hole goes all the way through to the lifter valley. This hole is the only one that goes through to the lifter valley and is used to supply oil to the timing chain. There is a special camshaft thrust plate bolt with a hole drilled through the center of it that is made to go in here and supply oil to the timing chain.

I have seen three different configurations from the factory in this area. One of them doesn't use the "drip tab", and one does. You can use the other three bolts without the center hole drilled for the other holes, and just leave this one open.

Second, I have seen the timing tab used, and then you should use the special bolt with the hole drilled through it. I like the timing tab as I feel that it directs the oil better to drip directly onto the chain, so that is how I like to build mine. However, it uses an anti-rotational tab that goes into the bottom (driver's side) bolt hole and does't allow for a bolt to go in there. That is why I use the bolt with the oil hole, as I would rather have 3 bolts holding the plate in place than only just 2.

Here the bolt hole is circled:

These pictures came from a block that I tore down, and they did not have the oil galley plugs in this block that I mentioned for the first picture. That's why I circled them in red here.

Here is a picture of the front of the camshaft thrust plate, this side faces away from the block:

Here is a picture of the back of the camshaft thrust plate, this faces toward the block:

Here's a picture of the camshaft thrust plate and timing tab assembled, but I have not put in the special bolt with the oil hole yet:

Here's a picture of the proper bolt with the oil hole drilled in it:

Here's a picture of that engine that I tore down that had the wrong bolt in there without the oil hole drilled. This won't let the oil get to the timing chain properly:

KEEP'EM Coming!!!

Treblig

Here's a shot showing all of the pieces go together for the timing gear:

Here is the timing gear all the way down, showing how much keyway sticks out:

Here is a side view with the bolt and washer shown:

Now here are some shots with the fuel pump eccentric showing how that fits:

A closer shot:

One from a little farther away:

Here it is with all of the parts together and the bolt in place:

Note: The small camshaft thrust plate bolts should all be torqued to 210 INCH-POUNDS (not FOOT pounds) --> there was a mis-print on this torque in some service manuals, it did not specify "inch" pounds.

The large bolt that holds the timing chain gear and fuel pump eccentric on should be torqued to 35 FOOT-POUNDS.

When installing the timing chain, I like to get the gears set before I install them and then turn the cam to line up with how the timing chain and gears are set. You should line up the mark on the cam gear to be at 6 o'clock, and the timing mark for the crankshaft at 12 o'clock. You also can put the cam mark at 12 o'clock and the crank gear at 12 o'clock, it will just be on the intake stroke instead of the compression stroke, but you can account for that when you install the distributor.

Here is a picture of the BACK of the oil slinger. It goes on the crankshaftafter the crankshaft timing gear. It fits loosely (but is held in place when the vibration damper is installed). Notice that the "flare" on the outside, this goes outward toward the front of the car, away from the gear (if you put it toward the gear, the slinger will get all chewed up).

Here is a shot of the front of the oil slinger. Notice the flare coming outward. This is the side that goes away from the timing gears when installed:

Here's a shot of the front of the engine all put together.

Here's a closer shot:

Here are two shots from an old worn engine. This is an old 318 with the old single chain and nylon coated gear. Notice how some of the nylonplastic has chipped off of the gears and the chain is so stretched, that it literally slipped off. This is why I run only double rollers and usually upgrade to the true roller double roller chains:

Another shot:

Now you can install the timing chain cover and water pump.

I just noticed that there were no pictures with the oil slinger installed. Here's how it goes: