AlV 69 Dodge GTS project

I took the car for a ride when I went to see it and noticed a vibration that pick up with the speed of the car.

Once I got it home in the garage I took a look at the drive line and I saw that the rear Universal Joint was shot. I also noticed that the tail shaft seal on the transmission was leaky (I'm guessing it was from the drive shaft vibration I was feeling).

I pulled the Drive shaft and was able to determine that I need to purchase the large size ujoint and which transmission seal to buy. While I was under there I was able to identify that I had the 741 8.75 differential (this will come in handy later). Check out the pic of the ujoint and drive shaft (you'll catch a glimpse of the 340 in this shot).

It turns out that the old ujoint was in really bad shape. The caps pressed into the dog bone at the end of the drive shaft were the correct size. While the caps set into the pinion yoke were the smaller size!??? huh? I rented this baby from auto zone to swap out the ujoint.

This seems more like it.

I replace the seal in the trans. The picture captures the old seal and my home made seal installation tool.

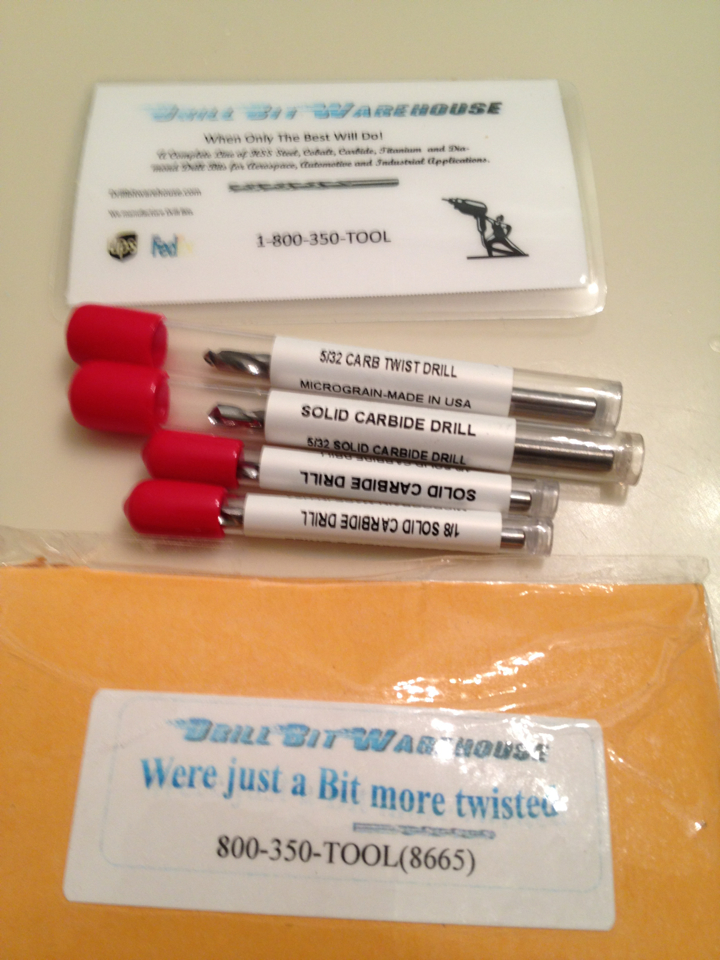

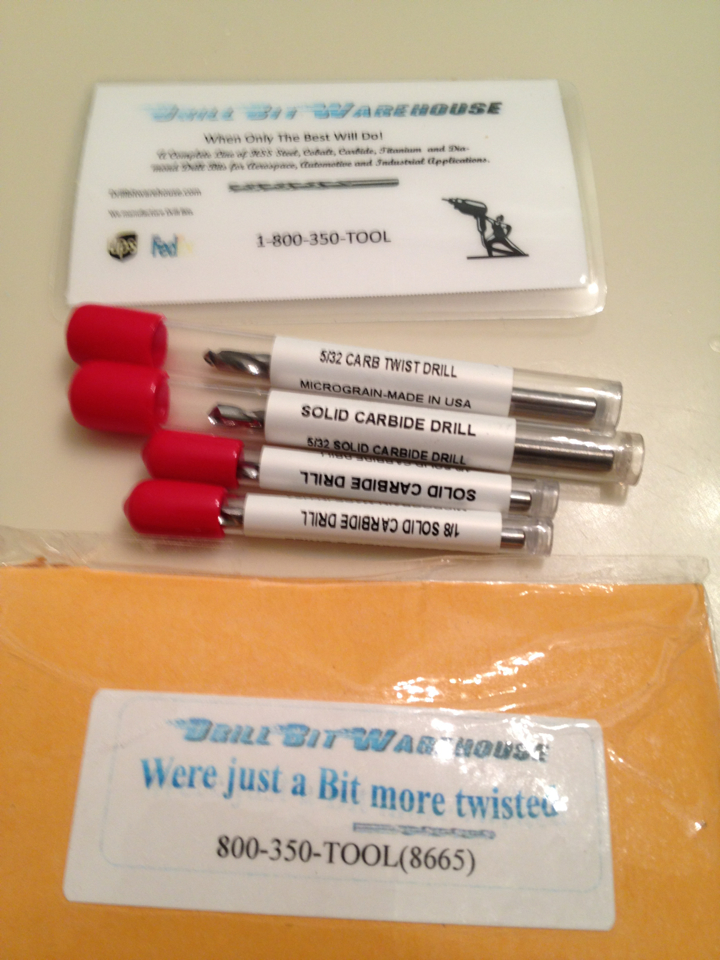

UGH! sheared a bolt on the pinion yoke during reassembly. I ordered The Alden drill out kit and replacement cap and bolts. I used a center punch and still wound up off. Guess that's just me LOL. Time for some left cut carbides and a lot of time under the car on the floor.

I came up with this idea to make a homemade jig to recenter the hole. I went out and bought two 1/8th inch cobalt bits and cutting oil. After two hours finally got the bits to start a nice cut. I worked the bit in about half way through the stud and inserted the drill out extractor.

I'd like to tell you that I was successful and I thought I was out of the woods but.... look at the picture, the empty space is where the extractor would go if it didn't break off in the bolt!! Grrr. now I have some solid carbide bits on order and a lot more drilling in my future. Not sure if it will even work. The next series may be me removing the rear to get at this problem (and I'll replace the differential gasket while it's out).

I've decided at this point to order some carbide drills and remove the rear diff to drill it out.

I buttoned it up at this point and took it for a test drive.

The vibration and shake was gone and I was able to adjust the brakes which worked much better. I ended up drilling through the Yoke and using new grade 8 bolt. The trans was still leaking from the the area behind the torque converter. I'll take a look a the trans in the future but decided to focus on the steering next.

I took the car for a ride when I went to see it and noticed a vibration that pick up with the speed of the car.

Once I got it home in the garage I took a look at the drive line and I saw that the rear Universal Joint was shot. I also noticed that the tail shaft seal on the transmission was leaky (I'm guessing it was from the drive shaft vibration I was feeling).

I pulled the Drive shaft and was able to determine that I need to purchase the large size ujoint and which transmission seal to buy. While I was under there I was able to identify that I had the 741 8.75 differential (this will come in handy later). Check out the pic of the ujoint and drive shaft (you'll catch a glimpse of the 340 in this shot).

It turns out that the old ujoint was in really bad shape. The caps pressed into the dog bone at the end of the drive shaft were the correct size. While the caps set into the pinion yoke were the smaller size!??? huh? I rented this baby from auto zone to swap out the ujoint.

This seems more like it.

I replace the seal in the trans. The picture captures the old seal and my home made seal installation tool.

UGH! sheared a bolt on the pinion yoke during reassembly. I ordered The Alden drill out kit and replacement cap and bolts. I used a center punch and still wound up off. Guess that's just me LOL. Time for some left cut carbides and a lot of time under the car on the floor.

I came up with this idea to make a homemade jig to recenter the hole. I went out and bought two 1/8th inch cobalt bits and cutting oil. After two hours finally got the bits to start a nice cut. I worked the bit in about half way through the stud and inserted the drill out extractor.

I'd like to tell you that I was successful and I thought I was out of the woods but.... look at the picture, the empty space is where the extractor would go if it didn't break off in the bolt!! Grrr. now I have some solid carbide bits on order and a lot more drilling in my future. Not sure if it will even work. The next series may be me removing the rear to get at this problem (and I'll replace the differential gasket while it's out).

I've decided at this point to order some carbide drills and remove the rear diff to drill it out.

I buttoned it up at this point and took it for a test drive.

The vibration and shake was gone and I was able to adjust the brakes which worked much better. I ended up drilling through the Yoke and using new grade 8 bolt. The trans was still leaking from the the area behind the torque converter. I'll take a look a the trans in the future but decided to focus on the steering next.