How to Megasquirt your 3G Hemi

Dyno runs were posted in another thread.

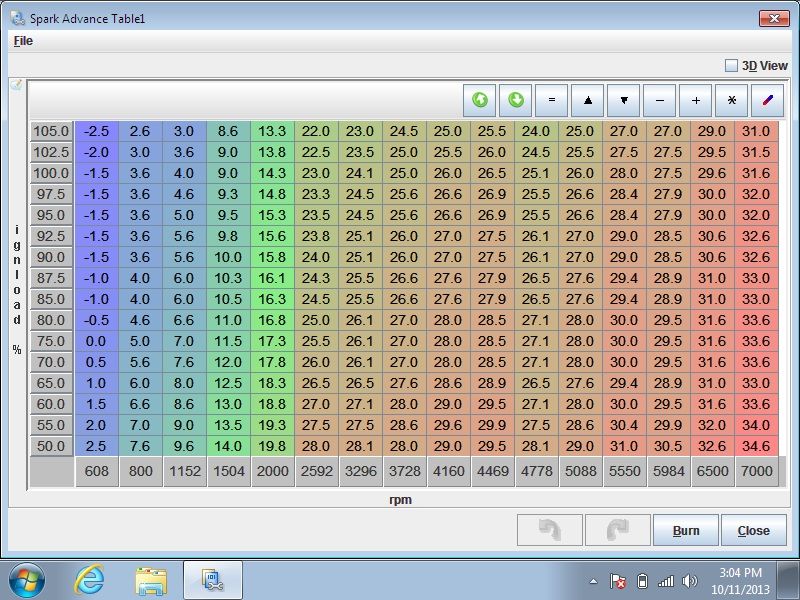

The math I posted for VE should've been close, but I don't think these 6.4 injectors flow what I assumed they did, skewing the numbers.

I have not had much issues with the ITB's. The linkage has adjusted itself more than once, and the airflow could use more balancing at idle, but it's plenty fine for everything I'm doing.

I have since killed this motor at the Texas mile. Ran it lean at 7200 rpm. Battery cable ground itself to chassis. 4 melted pistons. I put a bone stock 6.1 in for now, and will build a stroker to replace it.

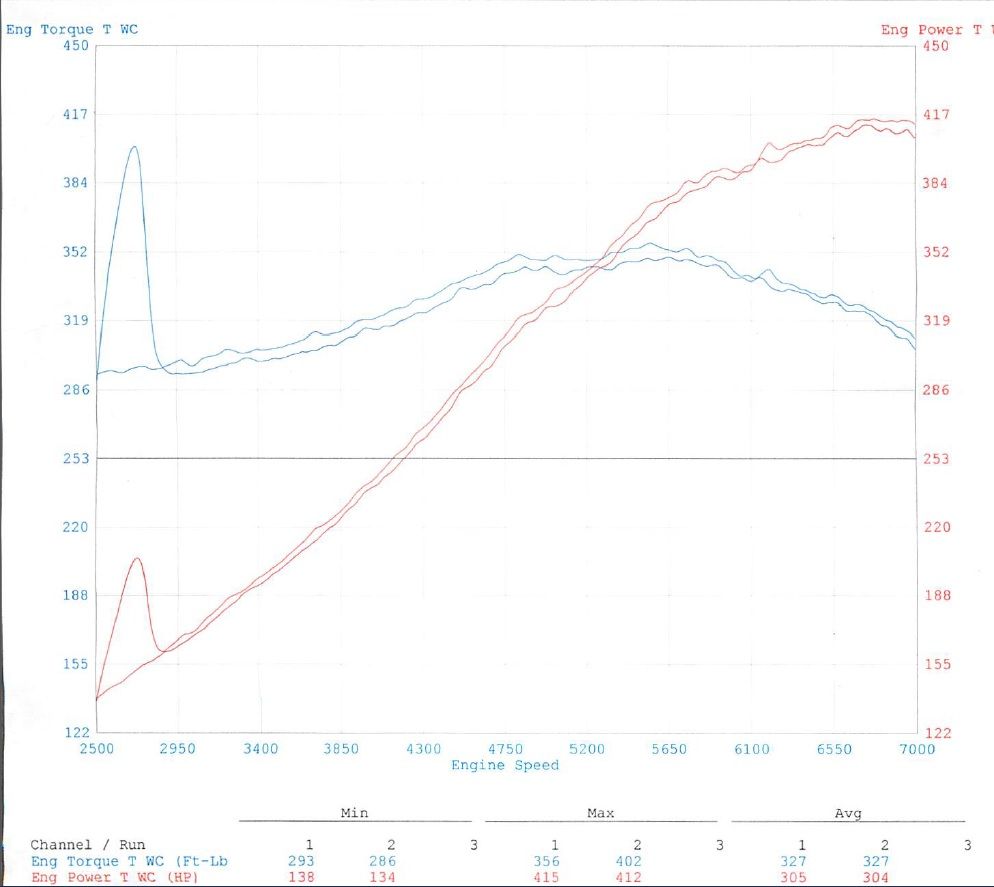

Here's the dyno numbers from the 5.7. Peppy little motor. RIP

Dyno runs were posted in another thread.

The math I posted for VE should've been close, but I don't think these 6.4 injectors flow what I assumed they did, skewing the numbers.

I have not had much issues with the ITB's. The linkage has adjusted itself more than once, and the airflow could use more balancing at idle, but it's plenty fine for everything I'm doing.

I have since killed this motor at the Texas mile. Ran it lean at 7200 rpm. Battery cable ground itself to chassis. 4 melted pistons. I put a bone stock 6.1 in for now, and will build a stroker to replace it.

Here's the dyno numbers from the 5.7. Peppy little motor. RIP