NodakDuster

Well-Known Member

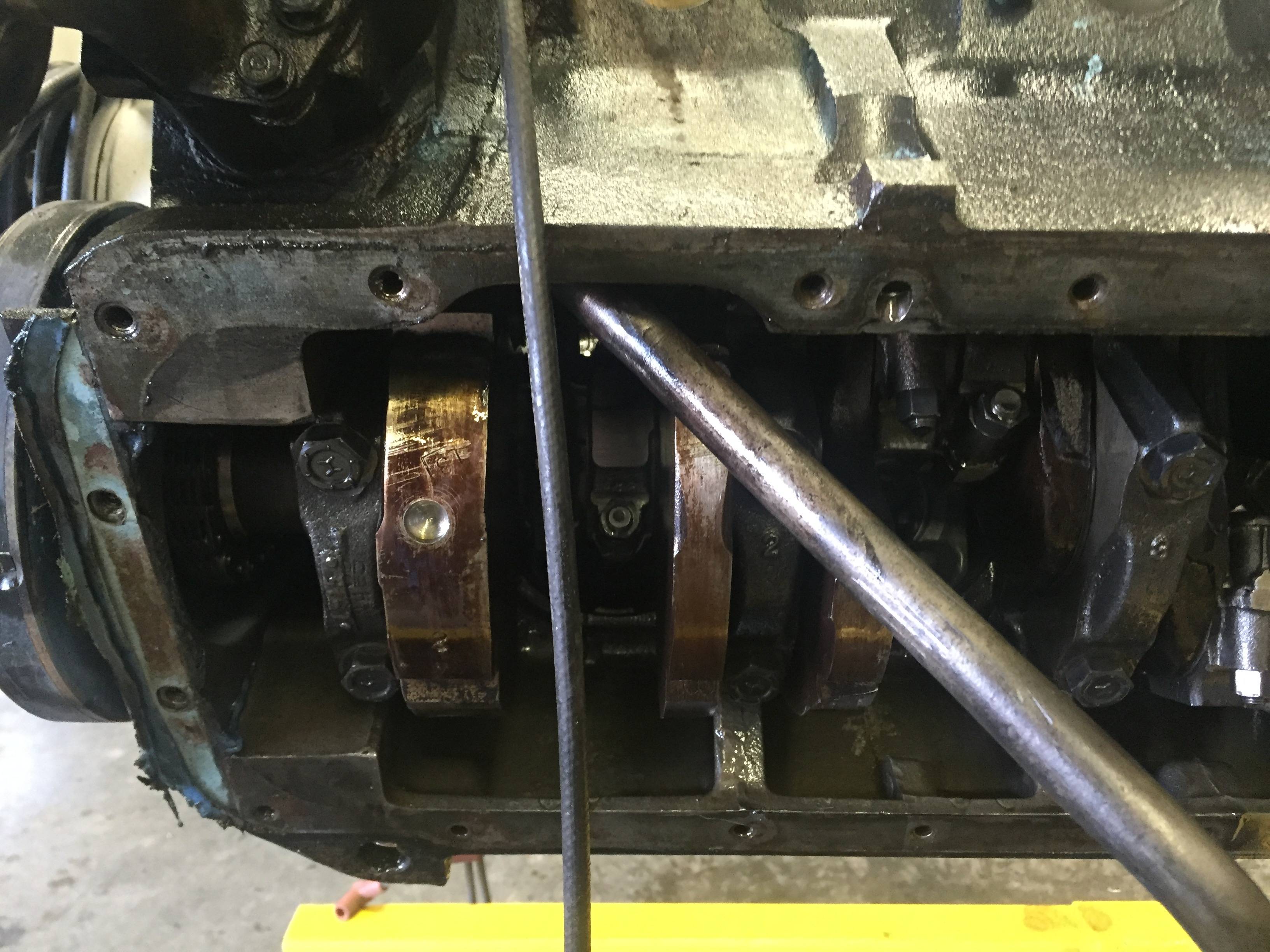

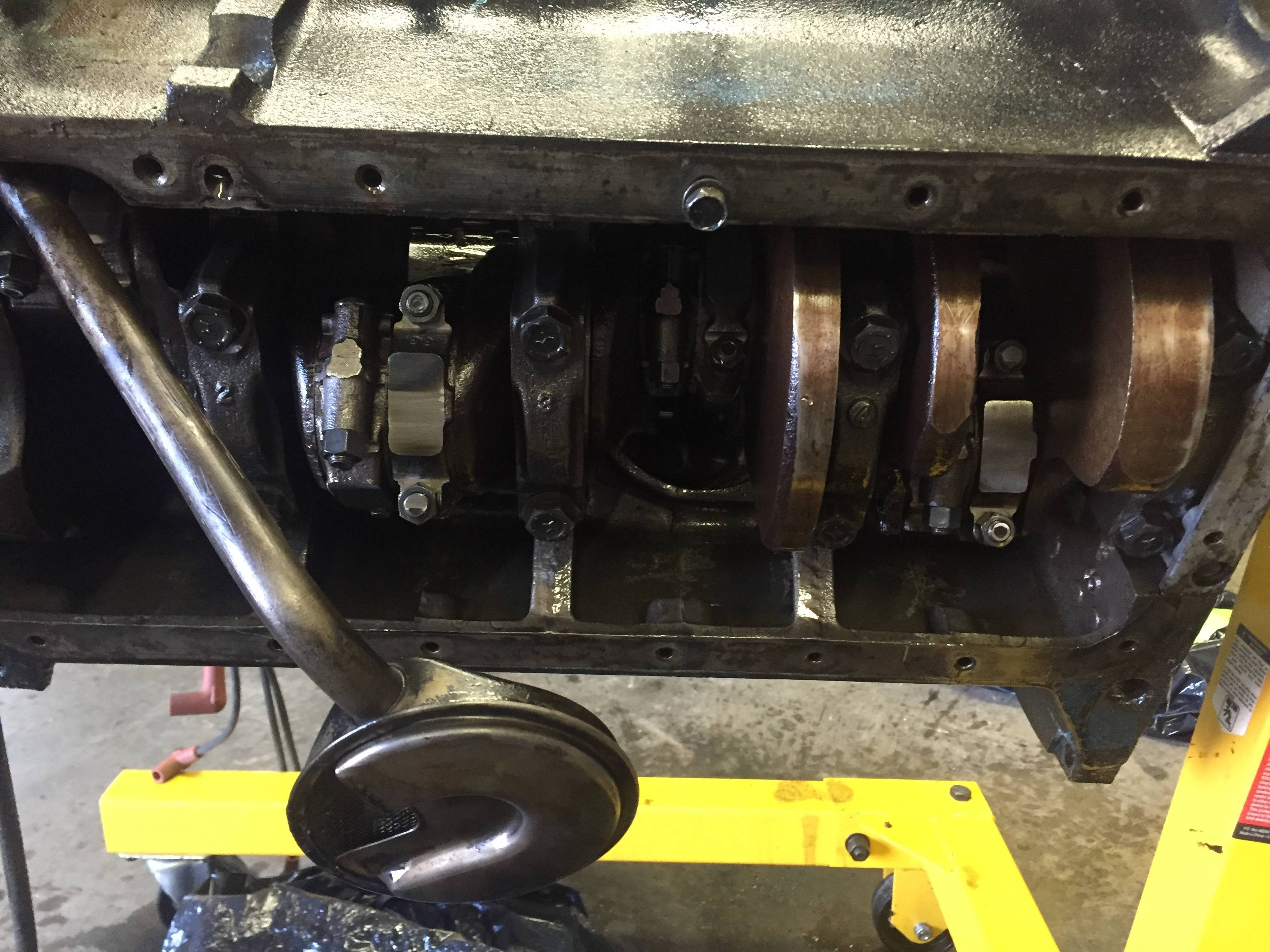

so a while ago I bought an engine from a member here who claimed it was a 383 stroked to a 426. Well today I was getting around to freshening up the engine before I installed it in my 73 Duster and started to tear it down to replace all the gaskets and give it a once over. Come to find out I got screwed on the stroker part. It is a 383 bored 30 over with l2135 flat top Pistons with no valve reliefs. It has a deck height of .020. The heads are 906 heads that have been mildly ported. I have yet to check the cam size out but is there much that can be done to bump performance up in this thing. With no valve relief and shallow deck height the odds of running a big cam in it are nil. It does appear like it was balanced during the rebuild. See pics below.

Is there much I can do with this thing or am I stuck with a slightly built engine that I would have to stick a ton in to improve performance?

Is there much I can do with this thing or am I stuck with a slightly built engine that I would have to stick a ton in to improve performance?