kingcrunch

Well-Known Member

It might fit, it might fit, it might fit!

Gotta check my measurements and put that 1500s control arm on stilts so it's close to the crossmember but i think we are on to something here!

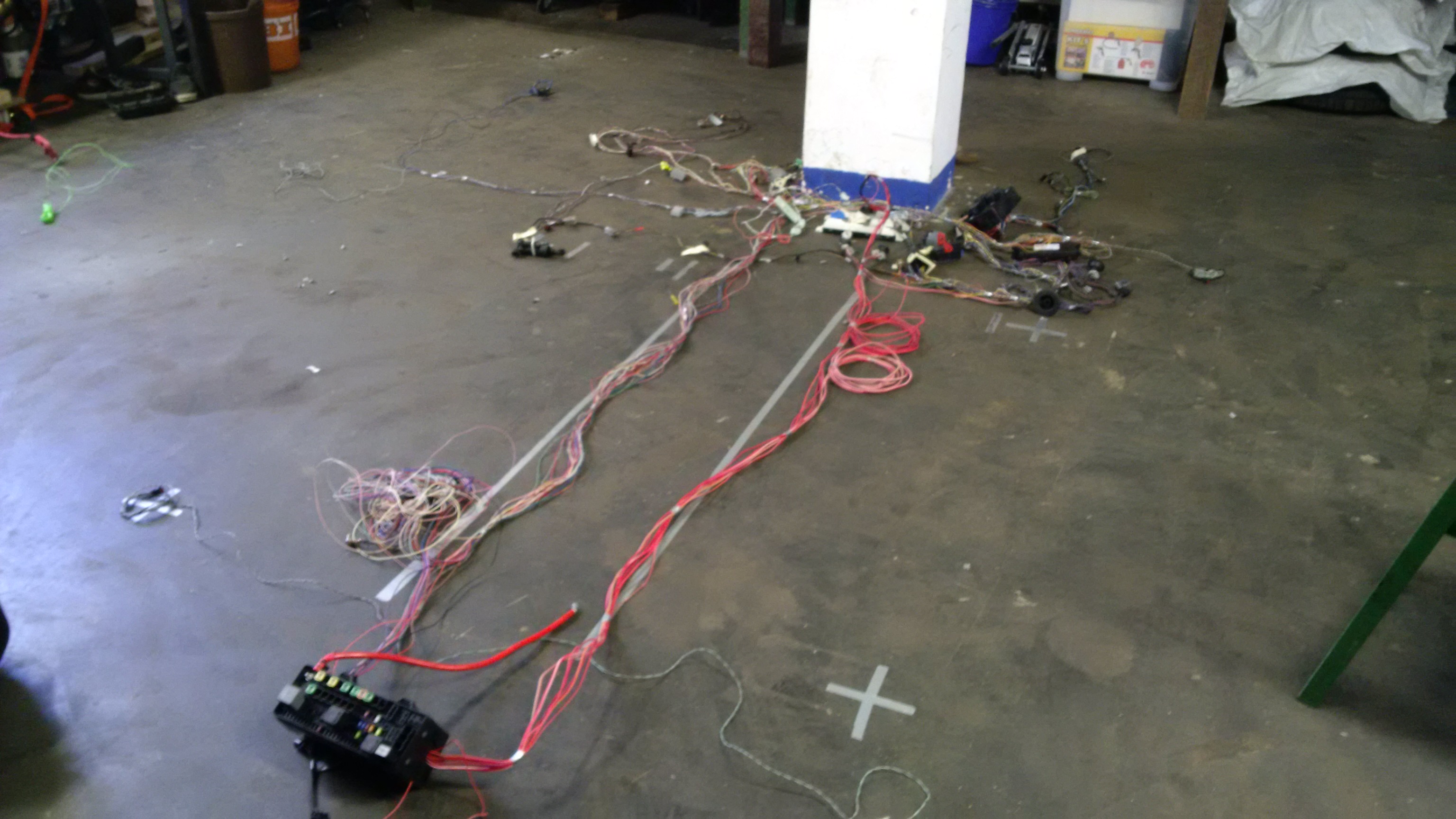

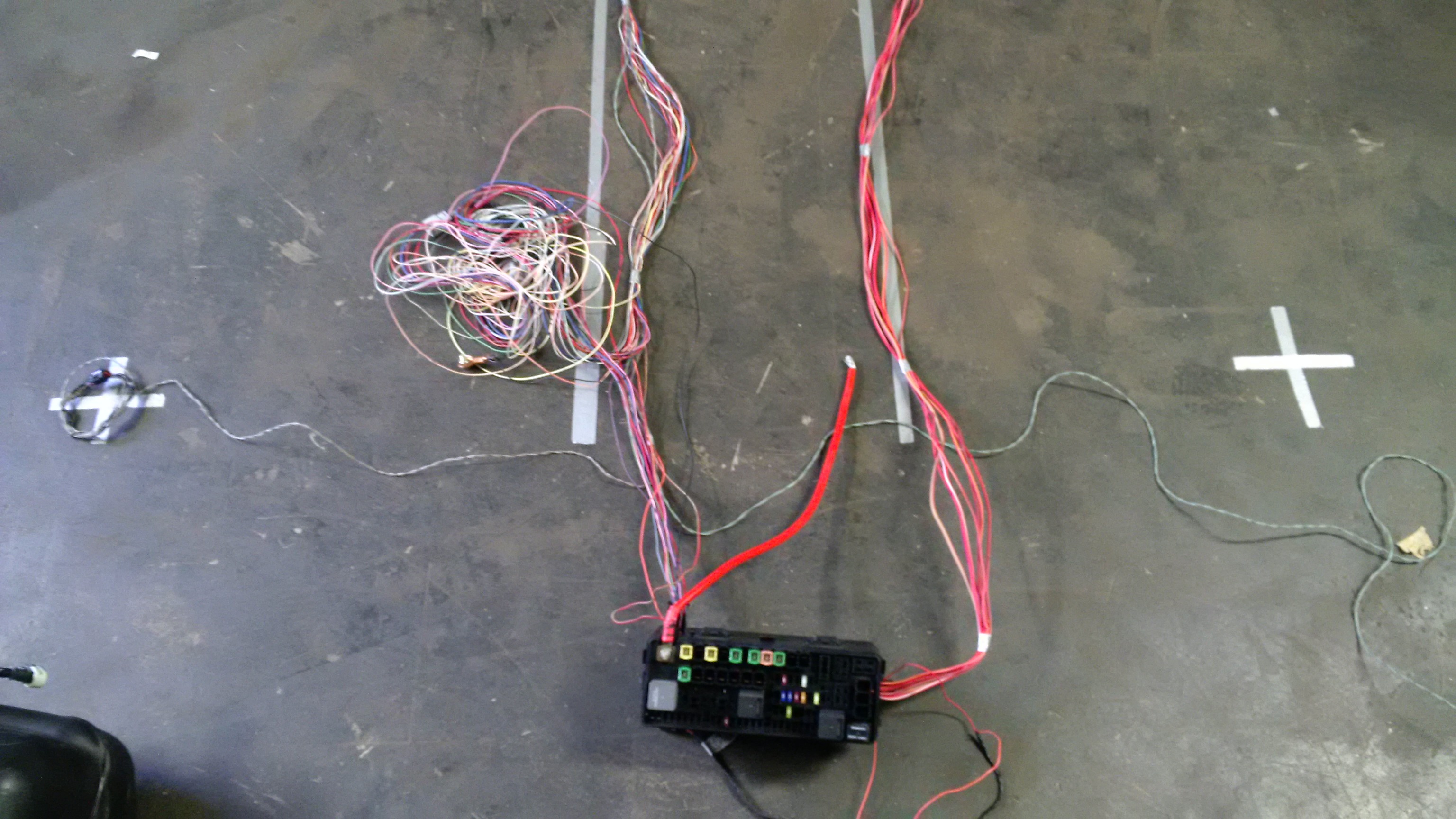

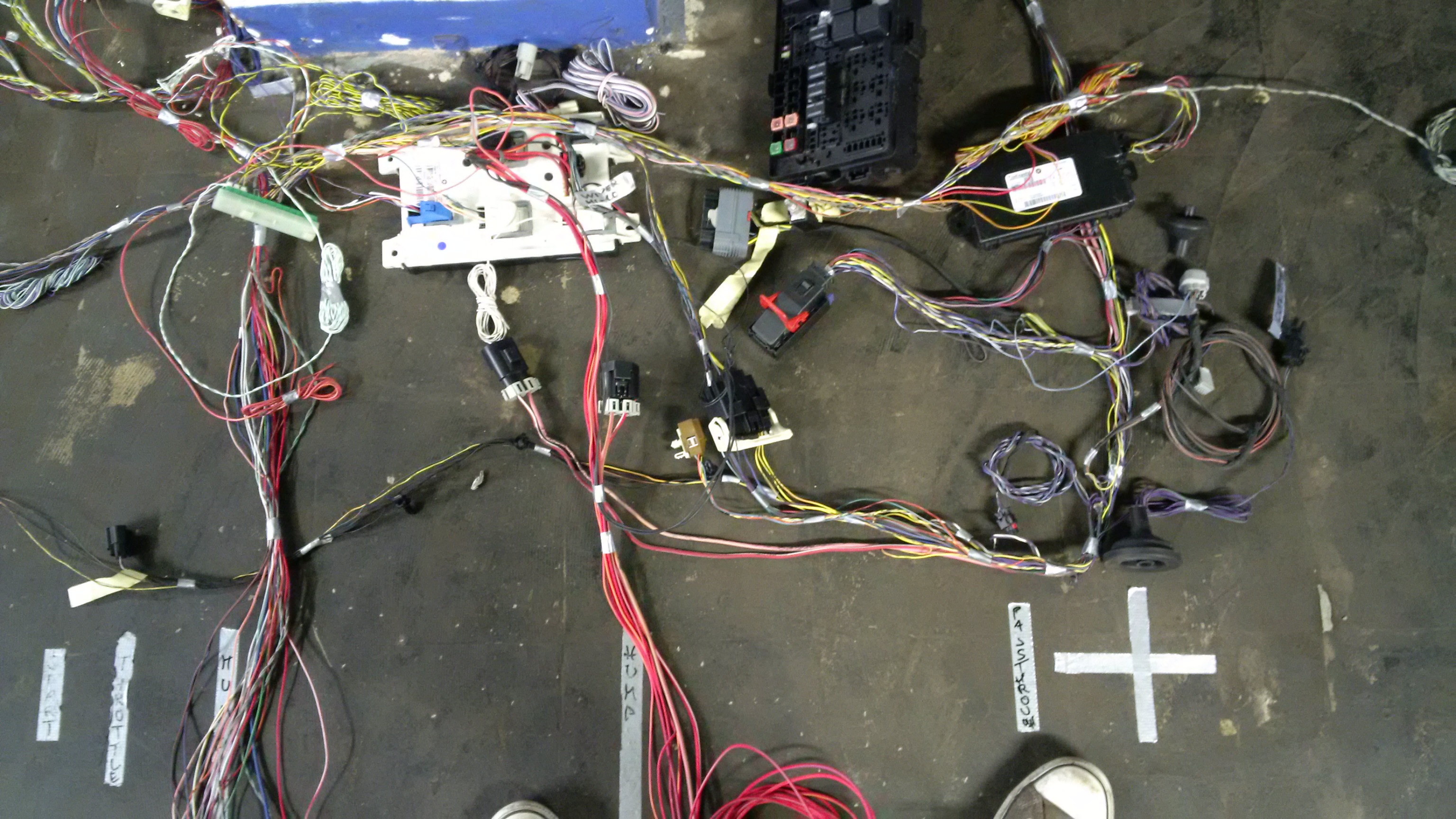

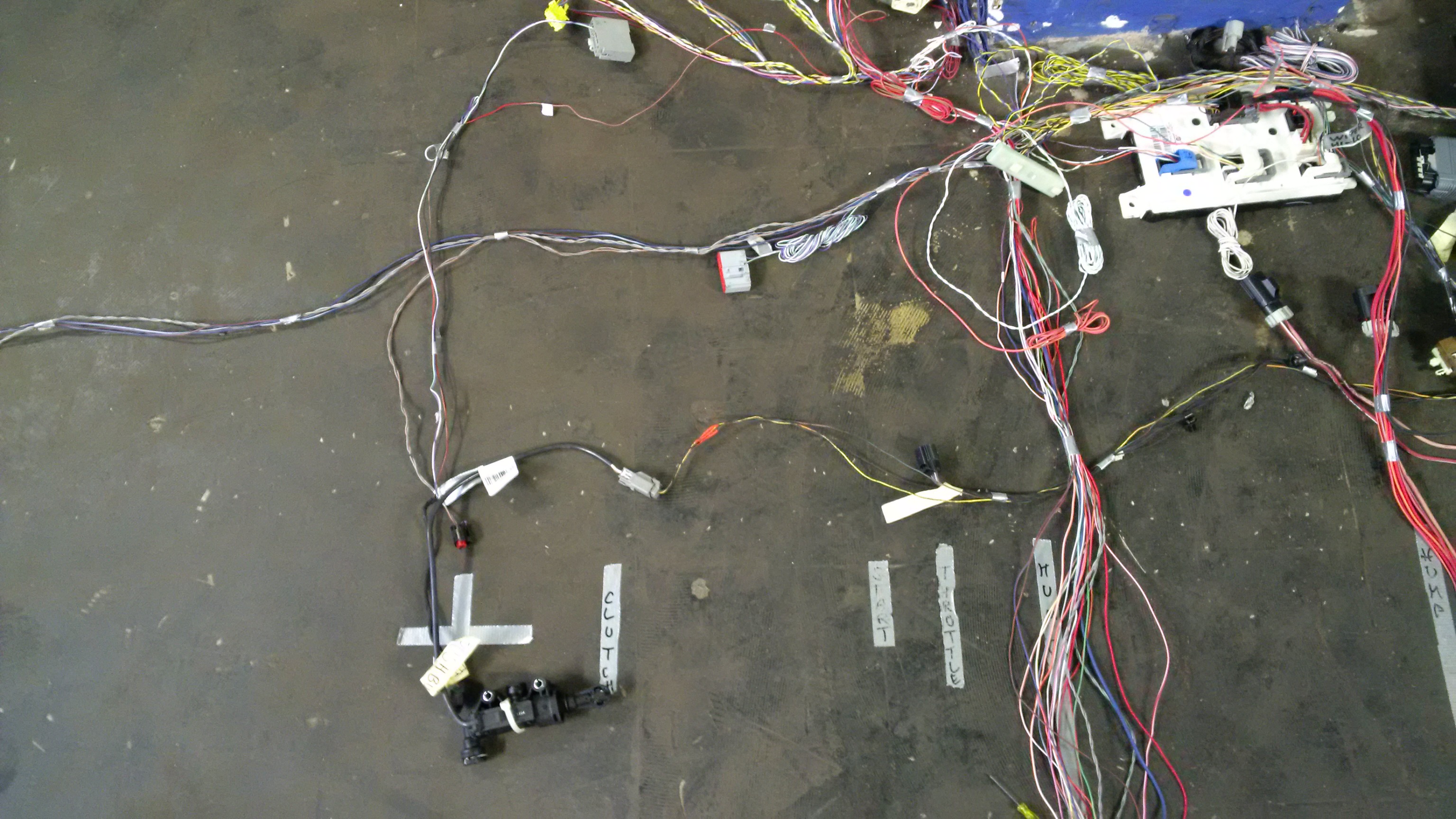

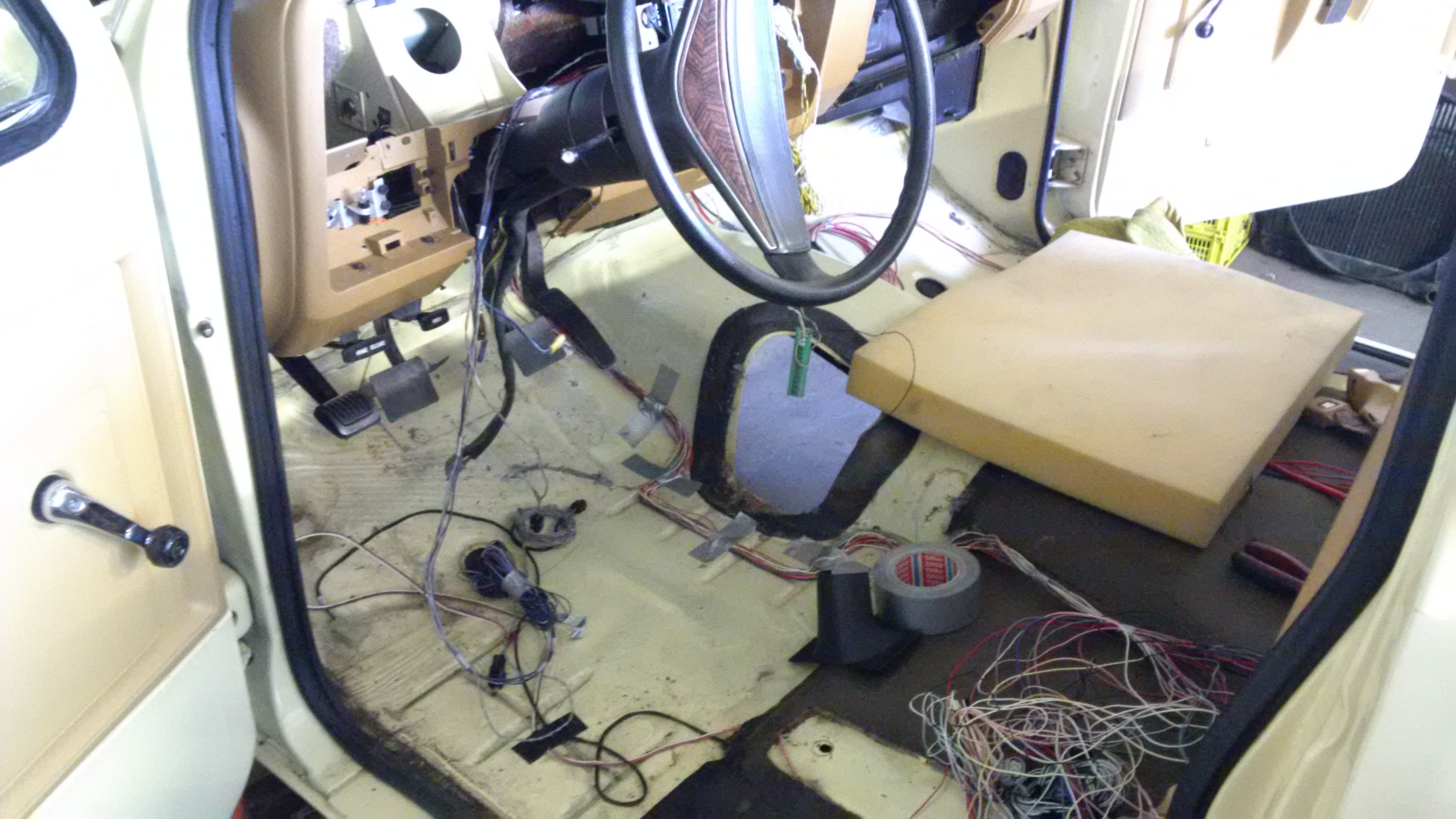

The rest of the day was spent by unwrapping the Challengers dash harness and beginning to understand its layout.

Slooooow process. 3 hours of unwrapping and understanding.

I need to get that FSM.

Gotta check my measurements and put that 1500s control arm on stilts so it's close to the crossmember but i think we are on to something here!

The rest of the day was spent by unwrapping the Challengers dash harness and beginning to understand its layout.

Slooooow process. 3 hours of unwrapping and understanding.

I need to get that FSM.

Last edited: