68 GT convertible project

I was planning on using a Taurus electric fan. I've read about them on this site and it seemed like a neat idea. I found complete new units at Rockauto for not much more than a replacement motor for the factory fan assembly. Before spending the money on a new one though, I wanted to test fit one. I went to a local salvage yard and found one already removed sitting on the inside of a Sable. I think I gave $15 for it. When I got it home, it was obvious there was no way it was going to fit. The core of the cc526 rad must sit a lot closer to the engine then the radiators most people are using for this swap. Even if I trimmed the back of the unit so the fan was basically touching the core, it wouldn't have cleared the water pump pulley.

Since that plan was a bust, I measured to see if I had room for a clutch fan. I'm using billet aluminum pulleys which are thicker then the stock pulleys. That pushes the clutch too close to the radiator so I have to use a fixed fan. I wanted to run a shroud but didn't have a stock piece to test and didn't really want to spend that much on a reproduction. I've got a few shrouds from various other vehicles up in the attic but they were all way to big. That meant I had to make one myself. Since my fabrication skills are very limited, I wanted to keep the shroud very simple. Giving the shroud a rounded top for fan clearance would have exceeded my skill level so I settled for a 15" fan which would keep the opening within the boundaries of the shroud "box".

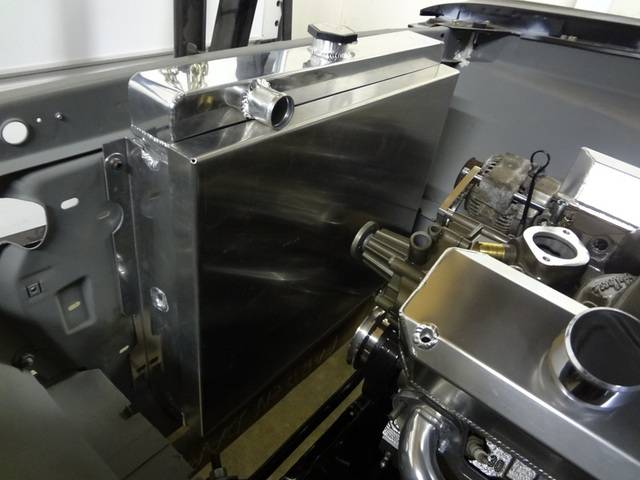

I bought a piece of aluminum at the local metal shop and used my small sheet metal brake to make the "box". My brake was really too small for the job but with some creative thinking, I made it work. Here I'm test fitting the "box" for the first time. It was hitting the upper and lower rad hose nipples so it needed to be modified.

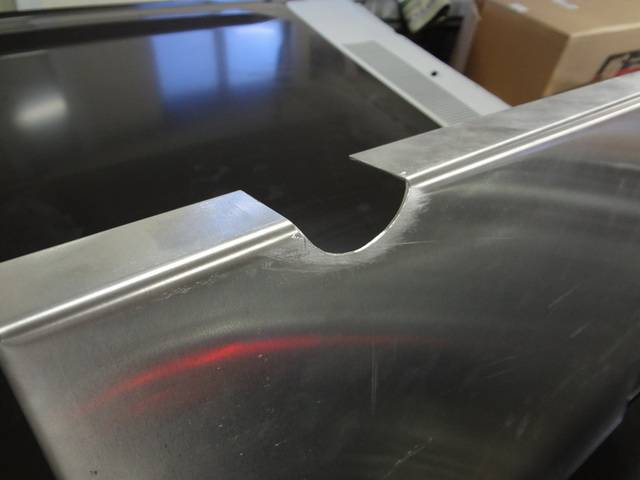

I used a piece of exhaust tubing as a guide and made a notch for the upper hose nipple. I was able to move the shroud up on the rad about an inch.

Now the "box" fit the radiator quite nicely.

I wanted the shroud to have a nice clean look so that meant having the ends welded instead of using bolts or rivets to hold it together. So, before I cut out the center fan hole. I gave the shroud to a friend for him to welded up. He welded the four corners and added in a half circle reinforcement inside the upper hose notch.

I was planning on using a Taurus electric fan. I've read about them on this site and it seemed like a neat idea. I found complete new units at Rockauto for not much more than a replacement motor for the factory fan assembly. Before spending the money on a new one though, I wanted to test fit one. I went to a local salvage yard and found one already removed sitting on the inside of a Sable. I think I gave $15 for it. When I got it home, it was obvious there was no way it was going to fit. The core of the cc526 rad must sit a lot closer to the engine then the radiators most people are using for this swap. Even if I trimmed the back of the unit so the fan was basically touching the core, it wouldn't have cleared the water pump pulley.

Since that plan was a bust, I measured to see if I had room for a clutch fan. I'm using billet aluminum pulleys which are thicker then the stock pulleys. That pushes the clutch too close to the radiator so I have to use a fixed fan. I wanted to run a shroud but didn't have a stock piece to test and didn't really want to spend that much on a reproduction. I've got a few shrouds from various other vehicles up in the attic but they were all way to big. That meant I had to make one myself. Since my fabrication skills are very limited, I wanted to keep the shroud very simple. Giving the shroud a rounded top for fan clearance would have exceeded my skill level so I settled for a 15" fan which would keep the opening within the boundaries of the shroud "box".

I bought a piece of aluminum at the local metal shop and used my small sheet metal brake to make the "box". My brake was really too small for the job but with some creative thinking, I made it work. Here I'm test fitting the "box" for the first time. It was hitting the upper and lower rad hose nipples so it needed to be modified.

I used a piece of exhaust tubing as a guide and made a notch for the upper hose nipple. I was able to move the shroud up on the rad about an inch.

Now the "box" fit the radiator quite nicely.

I wanted the shroud to have a nice clean look so that meant having the ends welded instead of using bolts or rivets to hold it together. So, before I cut out the center fan hole. I gave the shroud to a friend for him to welded up. He welded the four corners and added in a half circle reinforcement inside the upper hose notch.