Another Mopar Off My Bucket List - Barracuda Fastback

Wilwood uses an11/16"X20 thread size to screw the reservoirs into their master cylinders and a 9/16"X18 thread size in the bottoms of their reservoirs. Finding fittings that will allow us to extend the tanks beyond our planned recess is almost impossible without running flexible AN lines between the two. It looks like we'll have to mount the reservoirs on brackets to make things work.

I'd brought the driver's seat up from the basement and installed it in order to help figure out pedal placement. Hopefully the plastic will keep it from getting too dirty.

After further measuring of the firewall we've decided that we will have to replace the aluminum plates provided by Wilwood with new ones we'll have machined. We'll need the new pieces made an inch taller and increase the recess by making the inner plate an inch thicker. I believe we'll be making our own pedal arms down the road to get the fit that we want but we won't tackle that until we've got the full brake system installed and can test for proper throw distance.

Meanwhile we went ahead and gusseted the mounts for the overflow tank.

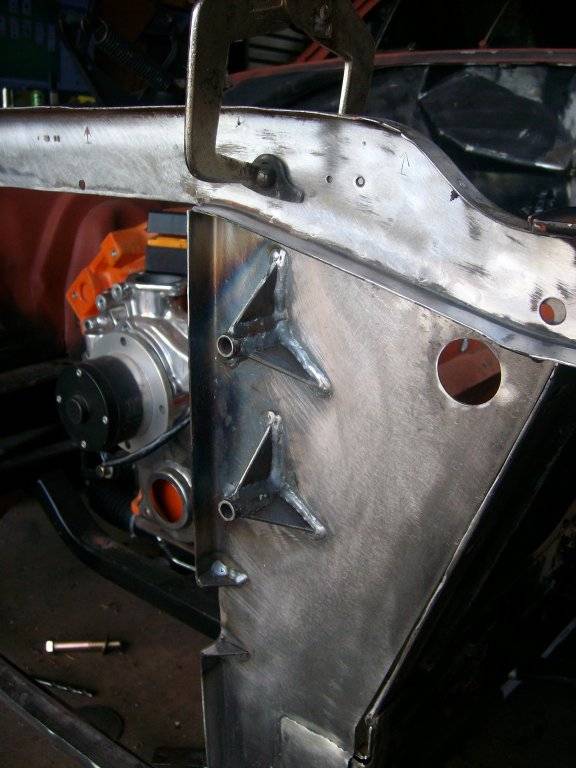

The formed angle next to the radiator opening was notched for brackets we're installing on the radiator. We also added gussets to that notched section.

Next I drilled holes in the upper sections of the new radiator wall for plug welds and also added a large 1&1/2" hole where future wiring will be run through

Spence and I spent a bit more time practicing tig welding before attaching tabs on the radiator made from 2" aluminum channel. It may not be a work of art but the welds look less like bird poop than my previous attempts.

Over all things are still shaping up.

I even spent a little time knocking off some of the surface rust that had formed on the left inner fender when the car sat outside last year.

Wilwood uses an11/16"X20 thread size to screw the reservoirs into their master cylinders and a 9/16"X18 thread size in the bottoms of their reservoirs. Finding fittings that will allow us to extend the tanks beyond our planned recess is almost impossible without running flexible AN lines between the two. It looks like we'll have to mount the reservoirs on brackets to make things work.

I'd brought the driver's seat up from the basement and installed it in order to help figure out pedal placement. Hopefully the plastic will keep it from getting too dirty.

After further measuring of the firewall we've decided that we will have to replace the aluminum plates provided by Wilwood with new ones we'll have machined. We'll need the new pieces made an inch taller and increase the recess by making the inner plate an inch thicker. I believe we'll be making our own pedal arms down the road to get the fit that we want but we won't tackle that until we've got the full brake system installed and can test for proper throw distance.

Meanwhile we went ahead and gusseted the mounts for the overflow tank.

The formed angle next to the radiator opening was notched for brackets we're installing on the radiator. We also added gussets to that notched section.

Next I drilled holes in the upper sections of the new radiator wall for plug welds and also added a large 1&1/2" hole where future wiring will be run through

Spence and I spent a bit more time practicing tig welding before attaching tabs on the radiator made from 2" aluminum channel. It may not be a work of art but the welds look less like bird poop than my previous attempts.

Over all things are still shaping up.

I even spent a little time knocking off some of the surface rust that had formed on the left inner fender when the car sat outside last year.