Target compression ratio A/J

I hear alot of different views on what you can and cant do on pump gas. Without getting too long winded I know there are alot of things that supposedly cant be done as far as exceeding a certain amount of compression. I dont believe that the limits are set in stone.

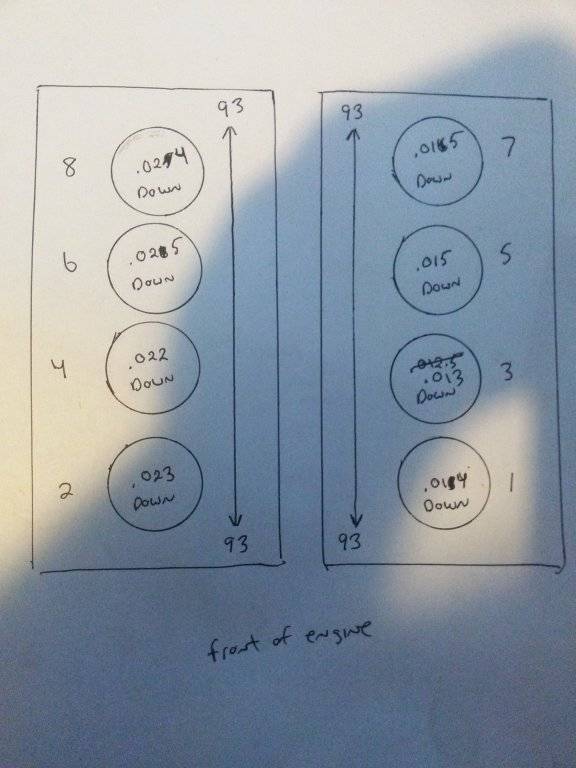

Here is where Im at with my 440 as far as how far down in the hole.

I dont know still though how the deck is in relation to the crank, I mean there are alot of variances here especially one side of the block compared to the other and can that be contributed to piston height, connecting rod variances, crankshaft abnormalities, casting/deck height abnormalities or the most likely culprit a combination of it all.

Without getting all nascar here Id still like to do it right.

The block has been bored .060 over, new pistons, crank turned, obviously all new bearings ect ect. Im not in nearly as deep as a guy that plans to race but Im not half assing anything that Im aware of either so far and so Id like to take advantage of every little trade secret I can to get the most out of this that I can.

Talking with the guy thats gonna cut my cam we figured in a zero deck clearance and so with that in mind whats the best way to get there at this point, what way makes the most sense?

I know I am missing important information like head gasket thickness ( I dont have one yet so I am open to anything ) valve relief CCs ( which I can call and get tomm ) Aluminum head CCs ( Im still waiting on my heads, should be here in a few days, supposed to be 84 CCs and Im pretty sure thats what they are gonna be ) Deck thickness ( I dont know yet where thats gonna end up ) stroke has changed since the cranks been cut but maybe the difference is irrelevant.

I know I scribbled out some info so just in case it cant be read cylinders are down in the hole as follows.

1- .014 2- .023

3 - .013 4- .022

5- .015 6- .025

7- .015 8- .024

I hear alot of different views on what you can and cant do on pump gas. Without getting too long winded I know there are alot of things that supposedly cant be done as far as exceeding a certain amount of compression. I dont believe that the limits are set in stone.

Here is where Im at with my 440 as far as how far down in the hole.

I dont know still though how the deck is in relation to the crank, I mean there are alot of variances here especially one side of the block compared to the other and can that be contributed to piston height, connecting rod variances, crankshaft abnormalities, casting/deck height abnormalities or the most likely culprit a combination of it all.

Without getting all nascar here Id still like to do it right.

The block has been bored .060 over, new pistons, crank turned, obviously all new bearings ect ect. Im not in nearly as deep as a guy that plans to race but Im not half assing anything that Im aware of either so far and so Id like to take advantage of every little trade secret I can to get the most out of this that I can.

Talking with the guy thats gonna cut my cam we figured in a zero deck clearance and so with that in mind whats the best way to get there at this point, what way makes the most sense?

I know I am missing important information like head gasket thickness ( I dont have one yet so I am open to anything ) valve relief CCs ( which I can call and get tomm ) Aluminum head CCs ( Im still waiting on my heads, should be here in a few days, supposed to be 84 CCs and Im pretty sure thats what they are gonna be ) Deck thickness ( I dont know yet where thats gonna end up ) stroke has changed since the cranks been cut but maybe the difference is irrelevant.

I know I scribbled out some info so just in case it cant be read cylinders are down in the hole as follows.

1- .014 2- .023

3 - .013 4- .022

5- .015 6- .025

7- .015 8- .024