273 rocker arm adjustment

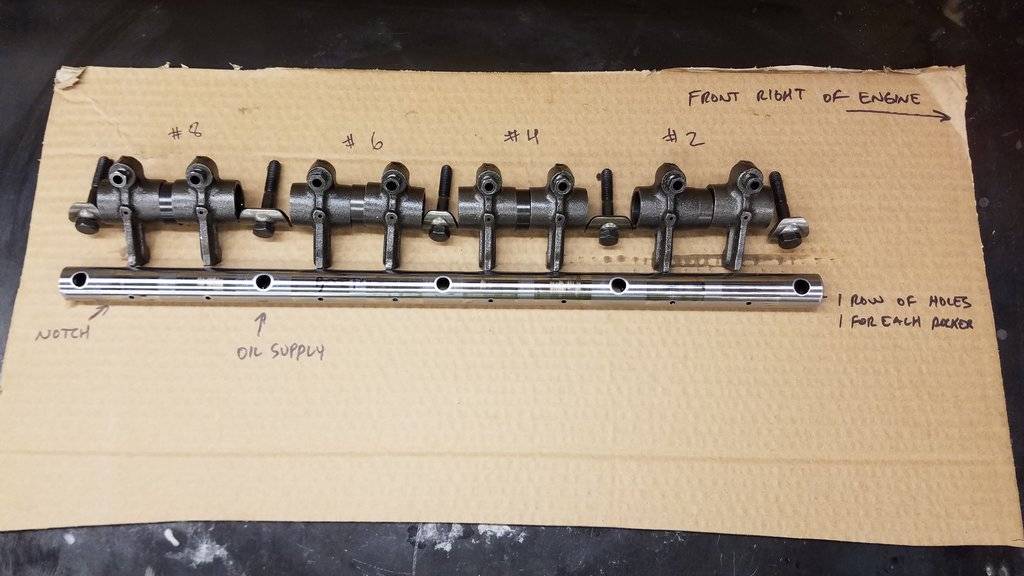

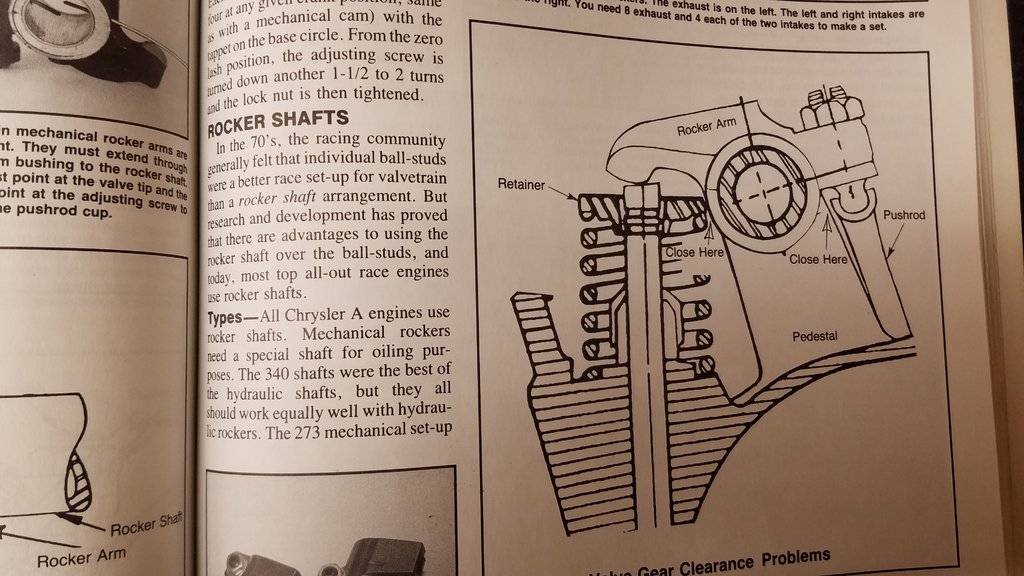

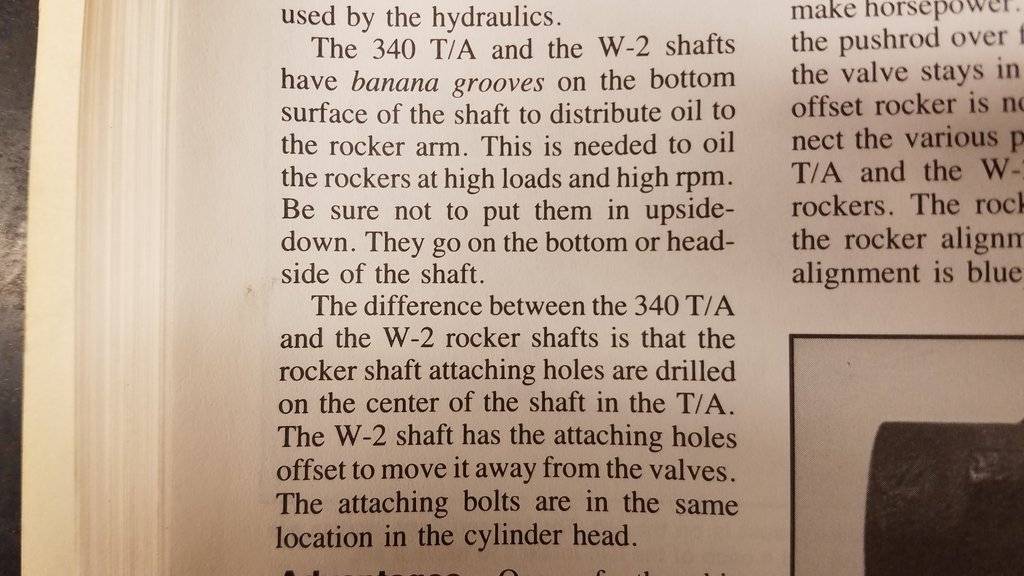

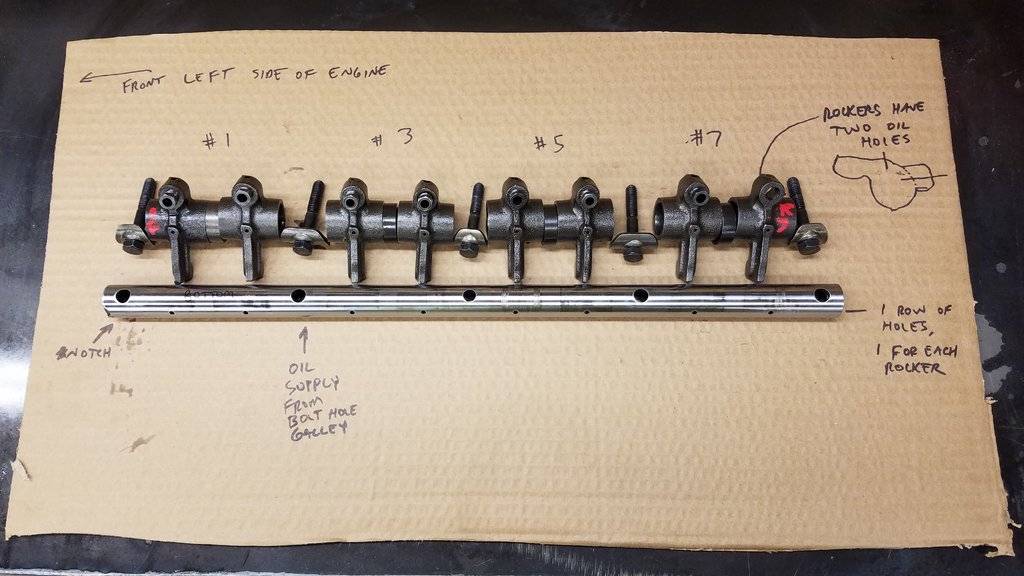

So the PO must have used the stock 340 shafts? My shafts have one hole per rocker. There is also talk about banana grooves. What would be the best bet, try to find the correct shafts (wrecking yards used, or new after market?) or drill the additional hole and add banana grooves? I think that is something i could do as long as the shafts aren't too hard and i had some measurements. I have heard of people using a die grinder to make the banana grooves.

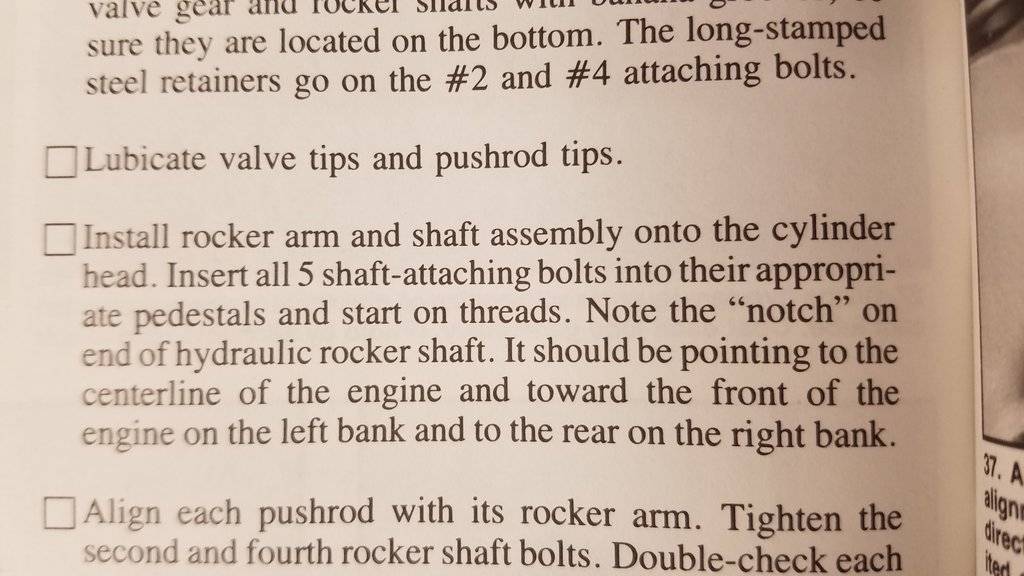

The notches on the shafts, the PO had them in backwards, some say it doesnt matter, anyway, i orientated them as per the book. The notches were made with an end mill, and they aren't the same depth compared to each other. Since i changed the orientation i will polish the shafts and the inside of the rocker arms, i have a pretty good method for that.

I went ahead and took out all 16 lifters, disassembled and cleaned them. I noticed most of them had very dark oil in side of them. they are all freely moving now. The book says not to pump them up when re assembling, i soaked them in oil and got the air out of them because it doesn't make sense to put them with out oil inside of them.

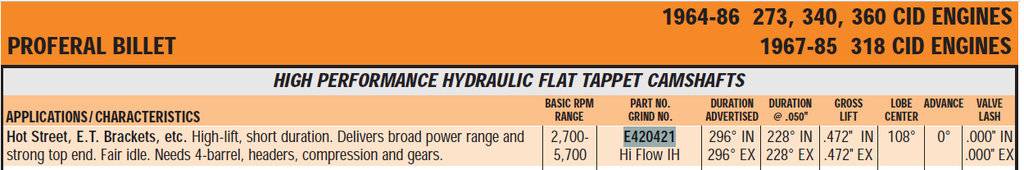

The cam card specs zero lash and its a hydraulic high lift cam. So i should set the adjuster screws to where i just start to feel drag on the push rods when i spin them in my fingers, i dont want to compress the piston inside the lifter any more than a C hair.

The wear pattern on the end of the rocker tip looks good, nice and centered both directions. so i dont think the geometery is off.

The only push rods that have wear on the sides of them from the heads are the ones that were bent. I have one push rod that is nice a straight. Question is why are the push rods bending? did the PO not have them adjusted right? Or could it be an over rev issue? cam card specs the rpm range is 2700 to 5700. What should i be shifting this thing at? I have a msd box that i could put a rev limiter in. the indicator on the rpm tach was set at 7000.

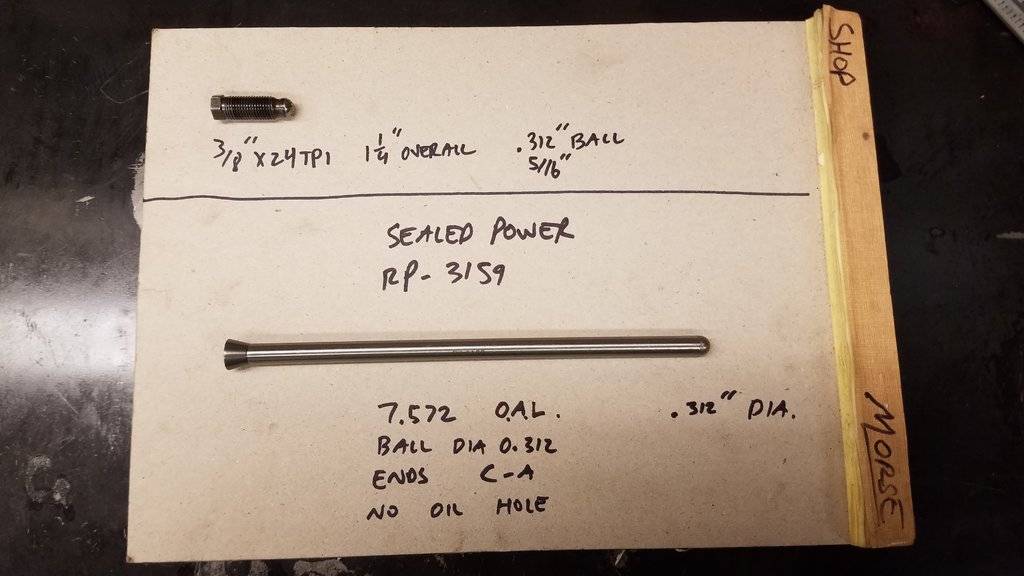

So then i thought, well most race engines use bigger push rods, 3/8", i have 5/16", but i think if i go with bigger push rods then they will rub on the heads. Also this push rod from sealed power RP-3159 is the only one of its kind, and i dont see alot of other options besides getting custom push rods made.

https://www.summitracing.com/parts/slp-rp-3159

Comp Cam 7821-16 pushrods (340 w/ 273 rockers)

We know where the metal was coming from, which was the oversize valve springs rubbing on the inside of the rocker arms. i can easily clearance these with the die grinder, i will probably use a template so they are all the same. some of the rockers castings vary and some of the rockers are untouched also.

Someone had mentioned going with the studs and lock nut set for the adjusters, i think this is a great idea, so i would have to face the top of the rocker where this lock nut would set. Think i could do that with a basic belt sander?

https://www.summitracing.com/parts/crn-99802-16

You are spot on about the oiling problem causing heat to the cup on the push rod, found one that is turning brown compared to the others.

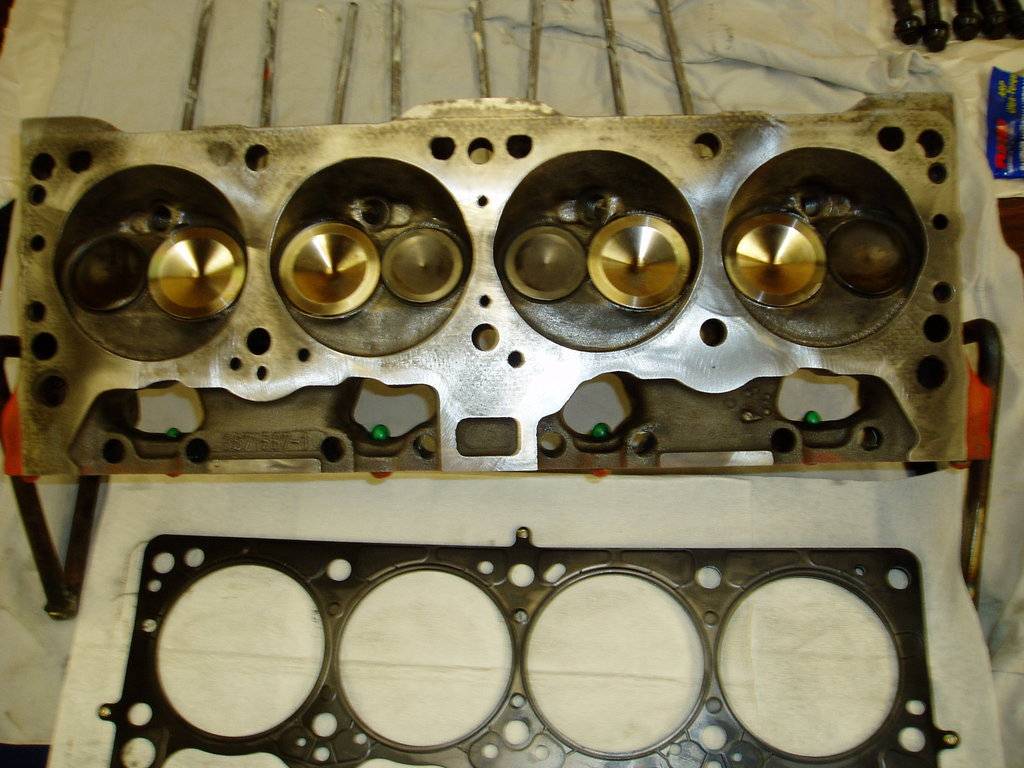

What do you think these intake valves are made of? whats the purpose?

I seems like i am constantly finding problems from the PO...i wonder when i will get all the wrinkles ironed out...

So the PO must have used the stock 340 shafts? My shafts have one hole per rocker. There is also talk about banana grooves. What would be the best bet, try to find the correct shafts (wrecking yards used, or new after market?) or drill the additional hole and add banana grooves? I think that is something i could do as long as the shafts aren't too hard and i had some measurements. I have heard of people using a die grinder to make the banana grooves.

The notches on the shafts, the PO had them in backwards, some say it doesnt matter, anyway, i orientated them as per the book. The notches were made with an end mill, and they aren't the same depth compared to each other. Since i changed the orientation i will polish the shafts and the inside of the rocker arms, i have a pretty good method for that.

I went ahead and took out all 16 lifters, disassembled and cleaned them. I noticed most of them had very dark oil in side of them. they are all freely moving now. The book says not to pump them up when re assembling, i soaked them in oil and got the air out of them because it doesn't make sense to put them with out oil inside of them.

The cam card specs zero lash and its a hydraulic high lift cam. So i should set the adjuster screws to where i just start to feel drag on the push rods when i spin them in my fingers, i dont want to compress the piston inside the lifter any more than a C hair.

The wear pattern on the end of the rocker tip looks good, nice and centered both directions. so i dont think the geometery is off.

The only push rods that have wear on the sides of them from the heads are the ones that were bent. I have one push rod that is nice a straight. Question is why are the push rods bending? did the PO not have them adjusted right? Or could it be an over rev issue? cam card specs the rpm range is 2700 to 5700. What should i be shifting this thing at? I have a msd box that i could put a rev limiter in. the indicator on the rpm tach was set at 7000.

So then i thought, well most race engines use bigger push rods, 3/8", i have 5/16", but i think if i go with bigger push rods then they will rub on the heads. Also this push rod from sealed power RP-3159 is the only one of its kind, and i dont see alot of other options besides getting custom push rods made.

https://www.summitracing.com/parts/slp-rp-3159

Comp Cam 7821-16 pushrods (340 w/ 273 rockers)

We know where the metal was coming from, which was the oversize valve springs rubbing on the inside of the rocker arms. i can easily clearance these with the die grinder, i will probably use a template so they are all the same. some of the rockers castings vary and some of the rockers are untouched also.

Someone had mentioned going with the studs and lock nut set for the adjusters, i think this is a great idea, so i would have to face the top of the rocker where this lock nut would set. Think i could do that with a basic belt sander?

https://www.summitracing.com/parts/crn-99802-16

You are spot on about the oiling problem causing heat to the cup on the push rod, found one that is turning brown compared to the others.

What do you think these intake valves are made of? whats the purpose?

I seems like i am constantly finding problems from the PO...i wonder when i will get all the wrinkles ironed out...