694spd

Well-Known Member

I ended up adding a little more free play in the linkage. I now have the factory spec of 5/32" at the end of the fork. I took the car for a drive and I'm still getting the grinding when I put the clutch down near the floor. Something is wrong with the clutch that I installed. The stock clutch linkage seems to be over travelling the travel limit of the fingers. Next step will be to pull the clutch back out. I hope I can send it back for a refund.

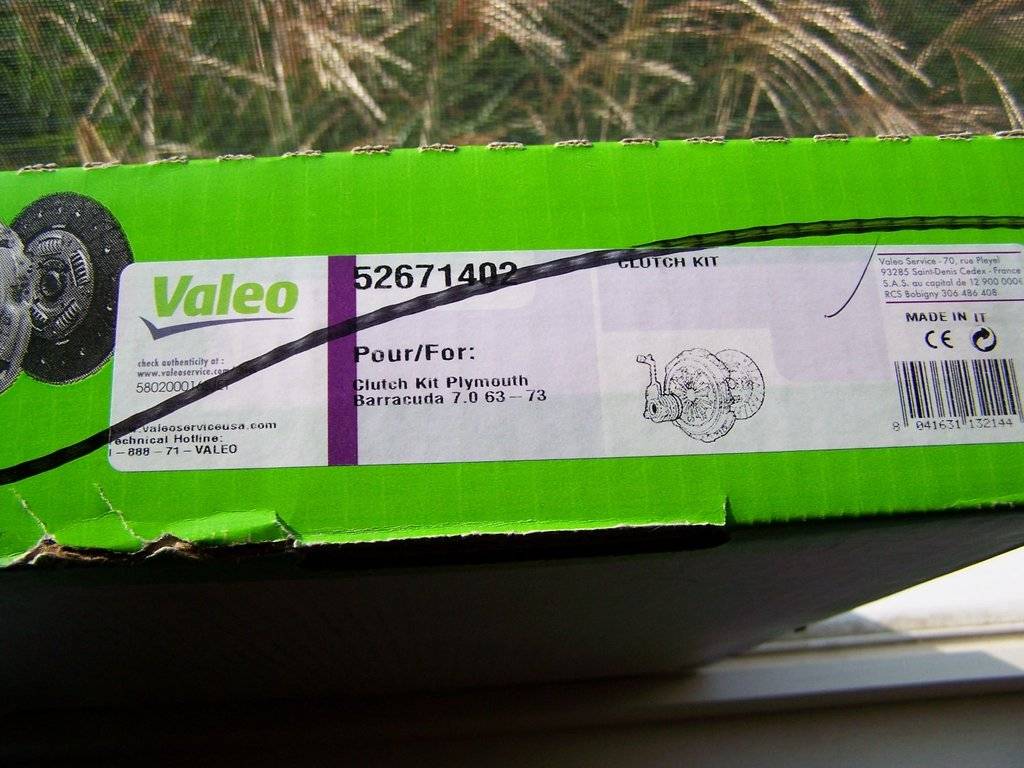

I should have expected problems when I saw how they marked the application on the box.

I should have expected problems when I saw how they marked the application on the box.