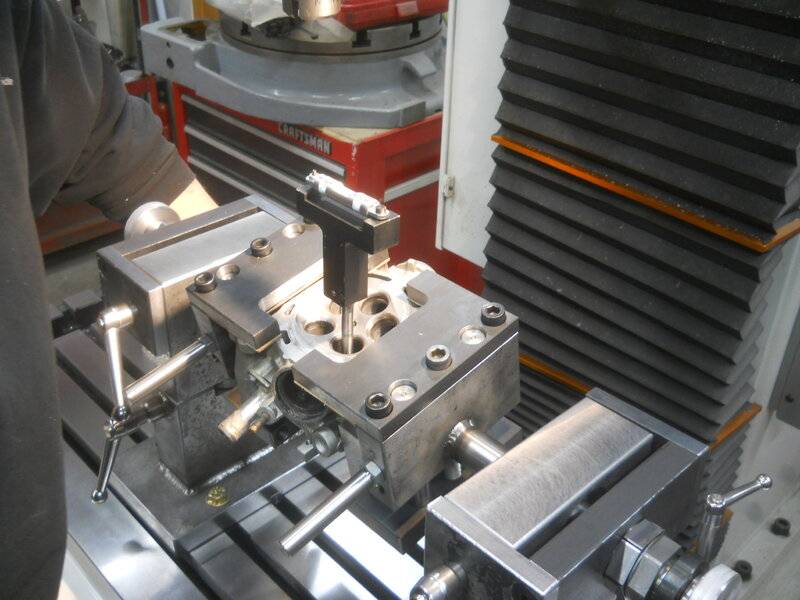

machine shop?

The machines are the smallest cost. Finding a bed mill is expensive you'll need that to do various block work. The tooling will be the biggest expense. One good cutter and you will need several is up to $1000 . A carbide end mill is $100 to $500. So tooling to do the work is over a couple hundred thousand. Torque plates for every block must be made or bought. $300-$700 each motor.

My son worked at a engine shop for years . He knew what machines to get to start off. He bought three machines new the rest he bought at sales and rebuilt them . Bridgeport mills are the only old mills you can get parts for easy. Make sure you have III phase electric. We are moving to a commercial property and getting III phase. Last month the electric bill using a phase converter was over $500. III phase hot tanks and block ovens take the most electric.

Make sure you have a good clientele and reputation . You'll get more work by word of mouth from satisfied happy customers.

\

Good young machinists are hard to find. He hired some and fired all of them. One guy was surfing the net on the phone while running a lathe.

The machines are the smallest cost. Finding a bed mill is expensive you'll need that to do various block work. The tooling will be the biggest expense. One good cutter and you will need several is up to $1000 . A carbide end mill is $100 to $500. So tooling to do the work is over a couple hundred thousand. Torque plates for every block must be made or bought. $300-$700 each motor.

My son worked at a engine shop for years . He knew what machines to get to start off. He bought three machines new the rest he bought at sales and rebuilt them . Bridgeport mills are the only old mills you can get parts for easy. Make sure you have III phase electric. We are moving to a commercial property and getting III phase. Last month the electric bill using a phase converter was over $500. III phase hot tanks and block ovens take the most electric.

Make sure you have a good clientele and reputation . You'll get more work by word of mouth from satisfied happy customers.

\

Good young machinists are hard to find. He hired some and fired all of them. One guy was surfing the net on the phone while running a lathe.