Common dash cluster issues question

................Let's see...............LOL

1....Cluster pc board harness connector pins. They can be repaired there is an OLD thread about this

2.....IVR connector contacts are sort of crimped into the board, and should be "soldered across" to the board traces

2....Gauge stud nuts are a joke. Replace them with "real" nuts and tighten/ loosen/ tighten them a few times to "scrub" the PC board contact area

3...Replace the IVR with a solid state replacement. A joint called RTE is one good one

4...Use a pencil eraser to clean / scrub the pc board where the lamp sockets make contact. Replace sockets as necessary, and "spread" / bend the contact fingers as needed for better contact. If you "go" LED bear in mind most of them are polarity sensitive, so if you get the LED/ socket in "wrongly" the LED won't light

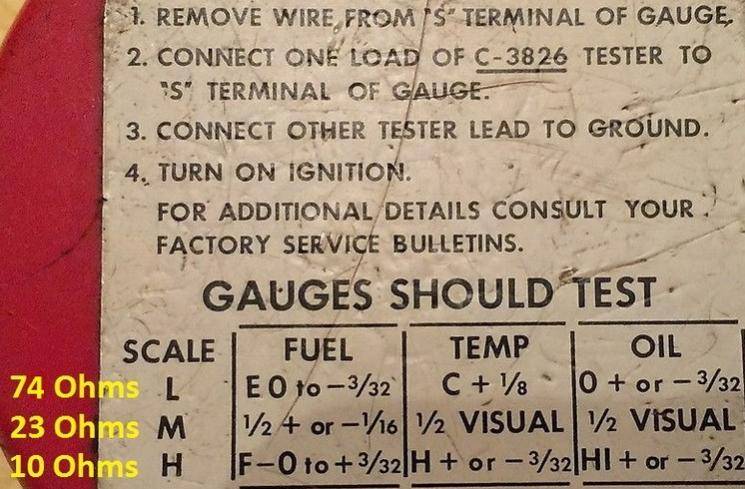

There are hundreds of threads on here about testing gauge calibration. If you have a rheostat or old gas sender, you can use that for a resistor. If you have an oil (Ralley) cluster, all three gauges use the same resistances. Here is a photo someone doctored, of a gauge tester. The yellow print are the resistor values for empty, mid scale, and full scale

................Let's see...............LOL

1....Cluster pc board harness connector pins. They can be repaired there is an OLD thread about this

2.....IVR connector contacts are sort of crimped into the board, and should be "soldered across" to the board traces

2....Gauge stud nuts are a joke. Replace them with "real" nuts and tighten/ loosen/ tighten them a few times to "scrub" the PC board contact area

3...Replace the IVR with a solid state replacement. A joint called RTE is one good one

4...Use a pencil eraser to clean / scrub the pc board where the lamp sockets make contact. Replace sockets as necessary, and "spread" / bend the contact fingers as needed for better contact. If you "go" LED bear in mind most of them are polarity sensitive, so if you get the LED/ socket in "wrongly" the LED won't light

There are hundreds of threads on here about testing gauge calibration. If you have a rheostat or old gas sender, you can use that for a resistor. If you have an oil (Ralley) cluster, all three gauges use the same resistances. Here is a photo someone doctored, of a gauge tester. The yellow print are the resistor values for empty, mid scale, and full scale