Axle Swap to upgrade to a 4.5" BP

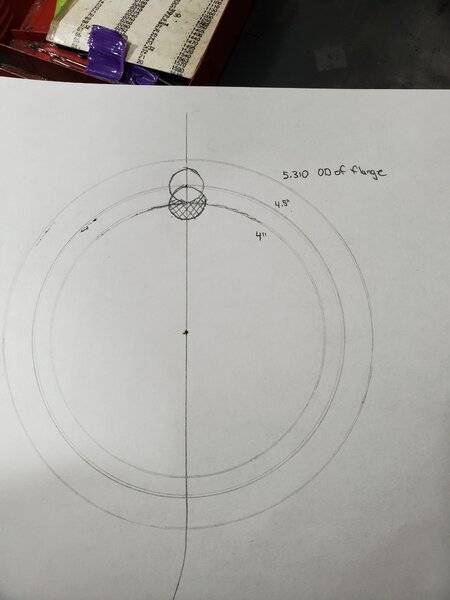

I agree. I think if you were going to weld on the flange it would be a lot less welding if you're only closing up the original holes. You are only moving the holes out a 1/4". You could just weld the bottom part of the hole or the shaded area in the drawing (drawn somewhat to scale). You would have to use an end mill to make the initial hole because of the interrupted cut then drill or ream to size. That said it might be easier to just weld the hole shut. The 4 1/2" pattern does get close to the edge of the flange. I wonder if the after market axles have a larger diameter flange?