Scary?: Rotors slightly contacting dust shields during hard corner (wheel bearings)

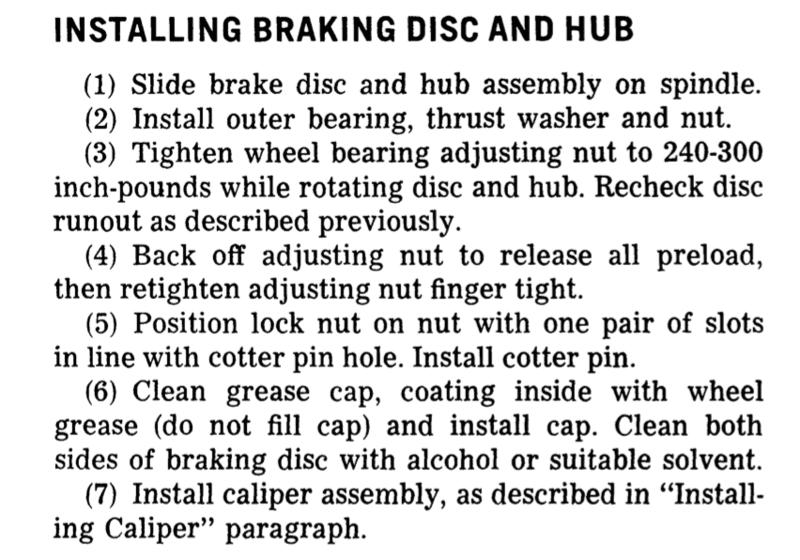

So the FSM says...

This is basically the way I've always done it. Grease and install the bearings, put the disk and hub on the spindle with the outer bearing. Tighten the nut until I can feel drag on the disk when I spin it, then back it off until it spins freely again. From there I tighten again and usually go a bit more than "finger tight", I shoot for zero end play on the rotor which is a little tighter than "finger tight" for me but should still be basically 0 preload, which I check by spinning the rotor and making sure I don't feel any resistance.

For me, if there's no noise or interference when you're going straight down the road but there is under hard cornering your wheel bearings are probably too loose still. Unless that dust shield is just a sliver off of the rotor at rest. I'd definitely inspect the dust shield and rotor to see exactly how close that is, maybe bend it back off the rotor a bit more, and recheck the wheel bearings.

For what it's worth, I don't run dust shields at all. Many cars never came with them. I find they're much better at trapping dust, rocks, and heat against the rotor than they are at keeping anything off of the rotor the rest of the time.

So the FSM says...

This is basically the way I've always done it. Grease and install the bearings, put the disk and hub on the spindle with the outer bearing. Tighten the nut until I can feel drag on the disk when I spin it, then back it off until it spins freely again. From there I tighten again and usually go a bit more than "finger tight", I shoot for zero end play on the rotor which is a little tighter than "finger tight" for me but should still be basically 0 preload, which I check by spinning the rotor and making sure I don't feel any resistance.

For me, if there's no noise or interference when you're going straight down the road but there is under hard cornering your wheel bearings are probably too loose still. Unless that dust shield is just a sliver off of the rotor at rest. I'd definitely inspect the dust shield and rotor to see exactly how close that is, maybe bend it back off the rotor a bit more, and recheck the wheel bearings.

For what it's worth, I don't run dust shields at all. Many cars never came with them. I find they're much better at trapping dust, rocks, and heat against the rotor than they are at keeping anything off of the rotor the rest of the time.