Under dash electrical fire

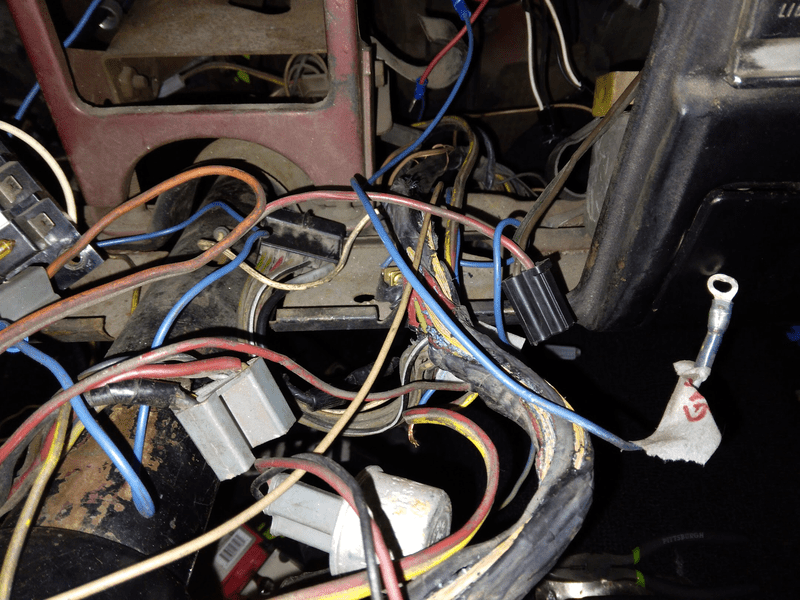

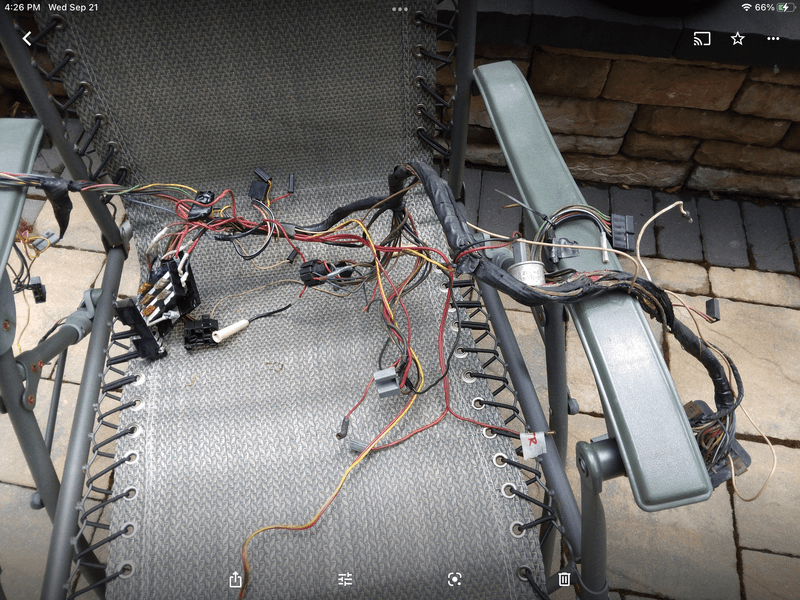

I had an electrical fire in the dashboard harness in May. I was lucky enough to get the positive battery cable off before the car burned up. (Lesson to all of you who wrench on the battery terminals - keep the positive one loose enough to remove by hand.) I saw the wire harness arc over to the dash frame were the metal strap holds part of it in place. The strap must have rubbed a hole in the insulation of the power wire to the amp gauge. There was no fusible link to protect it. I removed the harness a couple of days after this occurred and then I put it in the dishwasher (sans turn signal flasher) to clean it up. I did not know how I would go about repairing the harness, as I didn’t want to buy a bunch of different colored wires and I did not know what gauge they were (now I know that nearly all of them were 16 gauge). I ripped open the fused/melted portions of the harness and yanked each wire free of the melted mess. I watched utube videos of splicing wires in a car and noted that one mechanic dissuaded the use of solder in a splice. He highly recommended a splice crimp be used, and said the double crimp style was excellent for this (see photo below of sample connector and crimped tool). Cover the splices with heat shrink. The fourth photo above is the repaired harness, before I wrap it with the plain plastic tape like the factory did. I tested, cleaned and repaired all the gauges when I had it out. I deleted all the wires that went to the amp gauge and I will add a volt meter to the car later. The third photo shows all the removed wire sections.

I had an electrical fire in the dashboard harness in May. I was lucky enough to get the positive battery cable off before the car burned up. (Lesson to all of you who wrench on the battery terminals - keep the positive one loose enough to remove by hand.) I saw the wire harness arc over to the dash frame were the metal strap holds part of it in place. The strap must have rubbed a hole in the insulation of the power wire to the amp gauge. There was no fusible link to protect it. I removed the harness a couple of days after this occurred and then I put it in the dishwasher (sans turn signal flasher) to clean it up. I did not know how I would go about repairing the harness, as I didn’t want to buy a bunch of different colored wires and I did not know what gauge they were (now I know that nearly all of them were 16 gauge). I ripped open the fused/melted portions of the harness and yanked each wire free of the melted mess. I watched utube videos of splicing wires in a car and noted that one mechanic dissuaded the use of solder in a splice. He highly recommended a splice crimp be used, and said the double crimp style was excellent for this (see photo below of sample connector and crimped tool). Cover the splices with heat shrink. The fourth photo above is the repaired harness, before I wrap it with the plain plastic tape like the factory did. I tested, cleaned and repaired all the gauges when I had it out. I deleted all the wires that went to the amp gauge and I will add a volt meter to the car later. The third photo shows all the removed wire sections.