The importance of measuring bell housing runout.

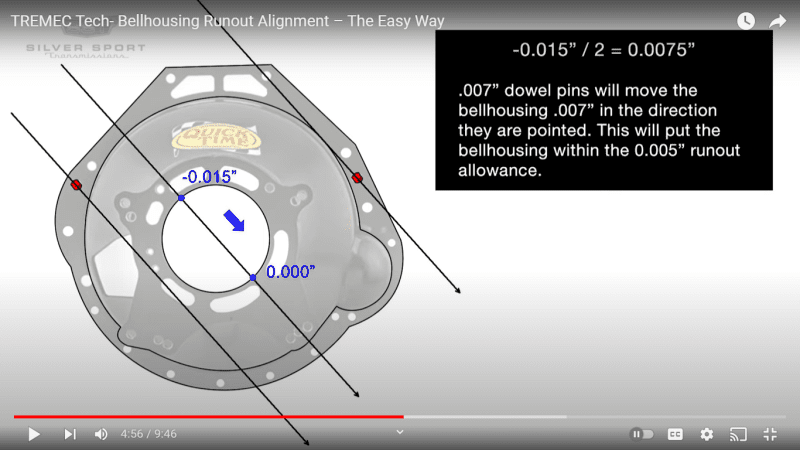

This is a screen shot of a Youtube video made by the company the Tremec kit came from.

You all know the phrase..."A picture is worth a thousand words" ?

Well, a video takes that concept a lot further. I had an eye opening moment while watching that video.

To recap, I mentioned first reading about measuring runout in a Mopar Action magazine where Rick Ehrenberg said "Spend the 20 minutes on this and get it right".

It pissed me off because it took me several hours to do this. 20 minutes? What the hell, man?

Watching this video, a couple of simple moves they did suddenly made total sense and it made me see how it is possible to do this with precision in far less time than before.

First, they aimed to find a zero point, then the point which was furthest away, the highest number.

We did that. The number was .081 or .082. THEN they RE-ZEROED the gauge at that highest point.

Now, that new zero point is the direction that the bell has to move to.

Yeah. THAT alone made my eyes perk up. It is so simple but makes sense.

In the case of this car, the zero point was still at 6:00 but the high number is at what was it....12:00 or 2:00? Regardless, THAT will be the new zero. THAT is where the bell has to shift toward to close that number.

Secondly, they installed their dowels with the offsets aimed to where they need to move the bell.

Again, so simple, I'm pissed that I didn't think of it. With my car, I think I did that but can't be sure.

The SST guys didn't test the runout at 4 points, 12 points or anything like that. They tested it at 2 points.....the highest number and lowest. Simple.

I feel like a kid with a new toy....I want to test what I've just learned.

This is a screen shot of a Youtube video made by the company the Tremec kit came from.

You all know the phrase..."A picture is worth a thousand words" ?

Well, a video takes that concept a lot further. I had an eye opening moment while watching that video.

To recap, I mentioned first reading about measuring runout in a Mopar Action magazine where Rick Ehrenberg said "Spend the 20 minutes on this and get it right".

It pissed me off because it took me several hours to do this. 20 minutes? What the hell, man?

Watching this video, a couple of simple moves they did suddenly made total sense and it made me see how it is possible to do this with precision in far less time than before.

First, they aimed to find a zero point, then the point which was furthest away, the highest number.

We did that. The number was .081 or .082. THEN they RE-ZEROED the gauge at that highest point.

Now, that new zero point is the direction that the bell has to move to.

Yeah. THAT alone made my eyes perk up. It is so simple but makes sense.

In the case of this car, the zero point was still at 6:00 but the high number is at what was it....12:00 or 2:00? Regardless, THAT will be the new zero. THAT is where the bell has to shift toward to close that number.

Secondly, they installed their dowels with the offsets aimed to where they need to move the bell.

Again, so simple, I'm pissed that I didn't think of it. With my car, I think I did that but can't be sure.

The SST guys didn't test the runout at 4 points, 12 points or anything like that. They tested it at 2 points.....the highest number and lowest. Simple.

I feel like a kid with a new toy....I want to test what I've just learned.