'69 Barracuda T56 swap, floor, cross member

So started out removing rear wheels and brake drums, all popped apart easy since its all low mileage stuff no rust. Took an inch pounds torque wrench spun yoke and zero inch pounds to rotate? Yet rear was silent and in excellent working condition when car was running less then 10K miles since total rebuild. Its a Randy Ring and Pinion 489 case 29 spline 7290 yoke. Yoke had nice smooth feel to it when rotating all seemed well before I took apart.

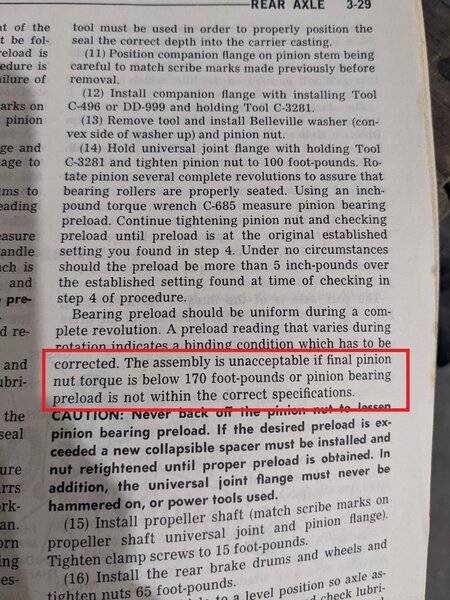

So used impact to run nut off and 7290 yoke pulled right off. Changed seal, put High Temp Thread Sealant into yoke spines, put blue loctite into nut, ran nut down with impact set on low setting. Then torqued to 150 ft/pounds. Removed holding tool still no inch pounds to rotate. So went ahead and torqued to 175 ft pounds. Still no inch pounds torque to rotate. But rotation was nice felt like it did with old yoke. 1969 Factory Service Manual for 489 case for seal replacement says min nut torque is 170. I went to 175 so I feel its good should not be any issues.

Holding tool is 5/16" thick, two holes drilled, and a small half circle to clear the socket. Metal used to be a frame for a pull behind lawn roller, you know, one of those steam roller looking things you fill with water from Sears to smooth out rough lawns? Kept that steel around for a few decades now came in handy today!

Will be ordering driveshaft now and once that comes ALL parts to get the car moving under its own power will be on hand.

The 1350 yoke and u-bolts are Strange from Summit Racing.

So started out removing rear wheels and brake drums, all popped apart easy since its all low mileage stuff no rust. Took an inch pounds torque wrench spun yoke and zero inch pounds to rotate? Yet rear was silent and in excellent working condition when car was running less then 10K miles since total rebuild. Its a Randy Ring and Pinion 489 case 29 spline 7290 yoke. Yoke had nice smooth feel to it when rotating all seemed well before I took apart.

So used impact to run nut off and 7290 yoke pulled right off. Changed seal, put High Temp Thread Sealant into yoke spines, put blue loctite into nut, ran nut down with impact set on low setting. Then torqued to 150 ft/pounds. Removed holding tool still no inch pounds to rotate. So went ahead and torqued to 175 ft pounds. Still no inch pounds torque to rotate. But rotation was nice felt like it did with old yoke. 1969 Factory Service Manual for 489 case for seal replacement says min nut torque is 170. I went to 175 so I feel its good should not be any issues.

Holding tool is 5/16" thick, two holes drilled, and a small half circle to clear the socket. Metal used to be a frame for a pull behind lawn roller, you know, one of those steam roller looking things you fill with water from Sears to smooth out rough lawns? Kept that steel around for a few decades now came in handy today!

Will be ordering driveshaft now and once that comes ALL parts to get the car moving under its own power will be on hand.

The 1350 yoke and u-bolts are Strange from Summit Racing.