Maybe I've learned a good lesson . . .

Or maybe the answer is simpler and we just need to take a swim in how a chassis dyno is used?

Here's my thinking this morning.

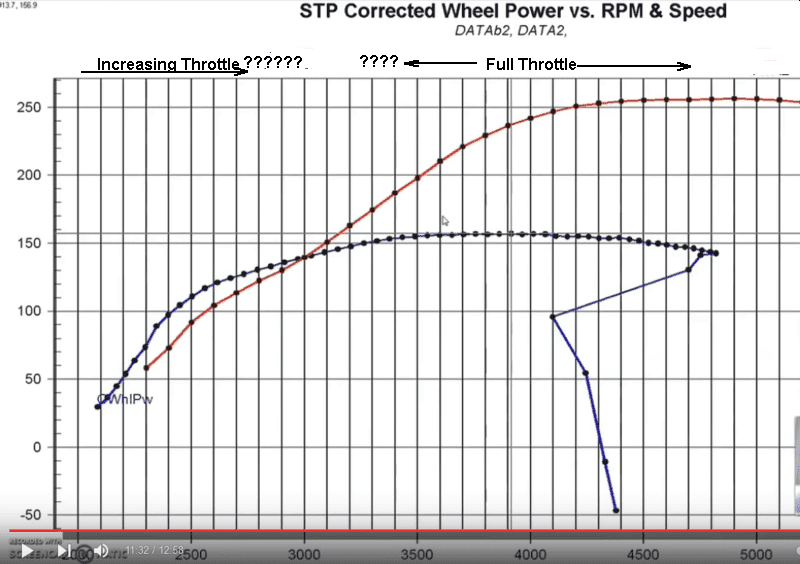

If this van has an automatic transmission (without a manual valve body) then the graph is showing both part throttle and full thottle,

and we don't know where that switches over.

When I've used a inertia dyno, the instructions are squeeze the throttle on to full throttle as quickly as possible without causing downshift.

I do this by using enough throttle to get it to upshift at a moderately high rpm and then squeeze the rest on quick so it won't downshift. Or I've run it so the 2-3 upshift is at full throttle. Then the results from the shift up are consistant. That technique isn't always going to work. On the dynojet I usually capture the at least the 2nd to 3rd shift.

So what we don't know in this chassis dyno chart is when full throttle was reached on the runs.

The software does some funky stuff when displaying the X-axis as rpm. Those points on the end of the blue line are pretty typical.

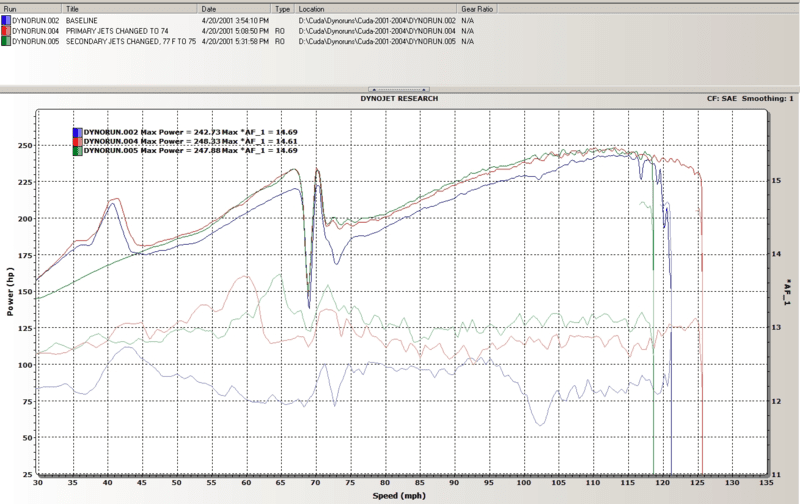

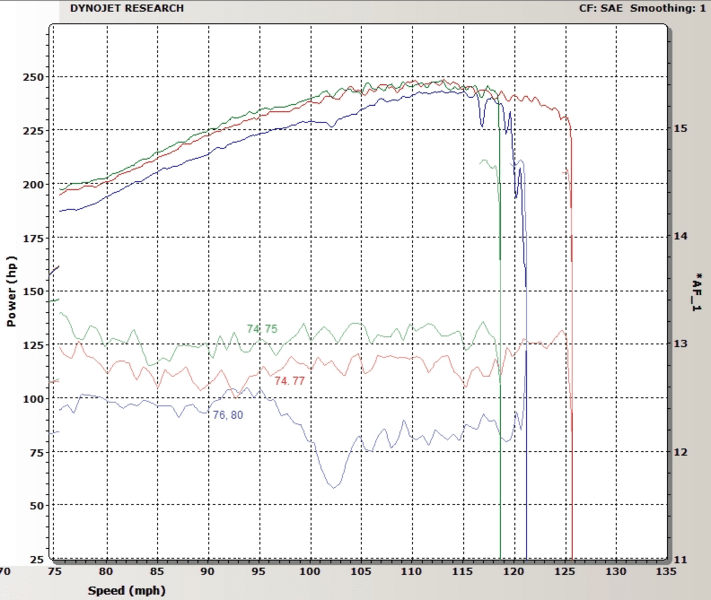

Here's some old runs of mine with full throttle 2-3 shift (again not the way its normally done AFAIK).

But the fair comparison begins at 75 mph or so.

yea yea yeah! Let's dive in!

Or maybe the answer is simpler and we just need to take a swim in how a chassis dyno is used?

Here's my thinking this morning.

If this van has an automatic transmission (without a manual valve body) then the graph is showing both part throttle and full thottle,

and we don't know where that switches over.

When I've used a inertia dyno, the instructions are squeeze the throttle on to full throttle as quickly as possible without causing downshift.

I do this by using enough throttle to get it to upshift at a moderately high rpm and then squeeze the rest on quick so it won't downshift. Or I've run it so the 2-3 upshift is at full throttle. Then the results from the shift up are consistant. That technique isn't always going to work. On the dynojet I usually capture the at least the 2nd to 3rd shift.

So what we don't know in this chassis dyno chart is when full throttle was reached on the runs.

The software does some funky stuff when displaying the X-axis as rpm. Those points on the end of the blue line are pretty typical.

Here's some old runs of mine with full throttle 2-3 shift (again not the way its normally done AFAIK).

But the fair comparison begins at 75 mph or so.