Rods in my Head, Part 2

Interesting one here about the Slant 6 block casting. They mention the wires.

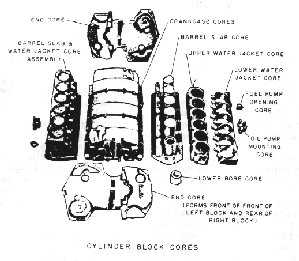

The RGFC blocks were cast 2 at a time, in a single sand mold made up of a cavity "rammed-up" into a box of "green sand", with several sand cores added, which create the hollow sections of the casting. The blocks were cast camshaft side down, crankcase to crankcase. Each mold cavity was loaded with over 20 "cores" made of baked oil sand. The major cores formed the crankcase, the cylinder deck-bores-valve tappet chamber, the water jacket, and the front and rear of the block. The main bearing webs and the crankcase pockets were made for both blocks by 3 large cores assembled together. The core that forms the front bay of one block forms the rear bay of the other, in other words, each end core formed the water pump scroll and the timing chain cavity on one block and the rear bell housing flange on the other. The water jacket cores were assembled to the crankcase and barrel slab cores using core wires. After the small cores for the fuel and oil pump pads are placed, the crankcase / water jacket / barrel slab core assembly was lowered into the outer sand mold and then the end cores were added to hold everything in place.

Here's a link to the article. Playing With Blocks

Interesting one here about the Slant 6 block casting. They mention the wires.

The RGFC blocks were cast 2 at a time, in a single sand mold made up of a cavity "rammed-up" into a box of "green sand", with several sand cores added, which create the hollow sections of the casting. The blocks were cast camshaft side down, crankcase to crankcase. Each mold cavity was loaded with over 20 "cores" made of baked oil sand. The major cores formed the crankcase, the cylinder deck-bores-valve tappet chamber, the water jacket, and the front and rear of the block. The main bearing webs and the crankcase pockets were made for both blocks by 3 large cores assembled together. The core that forms the front bay of one block forms the rear bay of the other, in other words, each end core formed the water pump scroll and the timing chain cavity on one block and the rear bell housing flange on the other. The water jacket cores were assembled to the crankcase and barrel slab cores using core wires. After the small cores for the fuel and oil pump pads are placed, the crankcase / water jacket / barrel slab core assembly was lowered into the outer sand mold and then the end cores were added to hold everything in place.

Here's a link to the article. Playing With Blocks