My 273 turned out to be a 318...what did I buy?

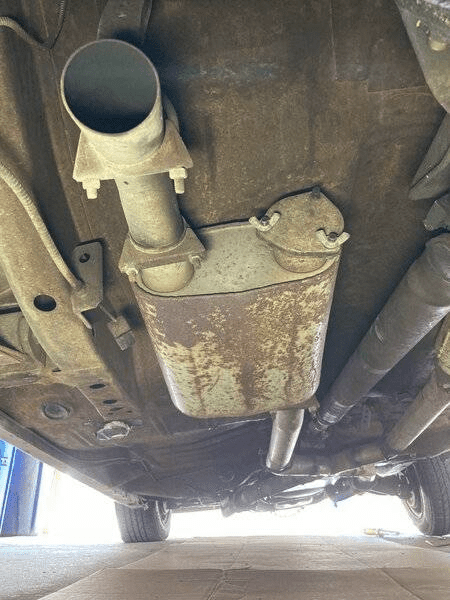

Looks like the connecting and right side parking brake cables missing

Good news - steel wasn't cut.

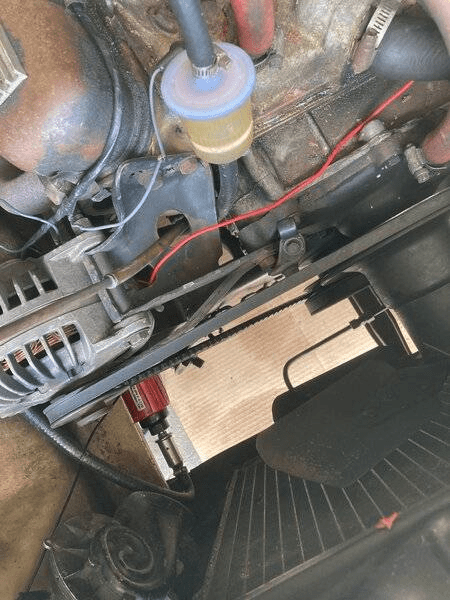

If it was me, I'ld look up the specifications on the pump for 1) fuel line connections, 2) electric power draw at X Volts for the range of flow and pressure 3) pressure flow relations and what if any maximum pressure it will create when dead headed (no flow out)

The use of fuel hose and lack of supports for it, and the lack of support for the electric power line are my main safety concerns. If they move around and touch something they will get cut or melted. If the wire vibrates the joints by the connecting terminals will weaken and eventually fail.

Plastic fuel filters were used by the factory and alone don't concern me. But they have to be well supported. Cuorrent location and orientation is OK - in fact close to factory on some engines. Its the lack of support that is concerning. Plastic can melt or get cut even though its a better insulator than steel or aluminum.

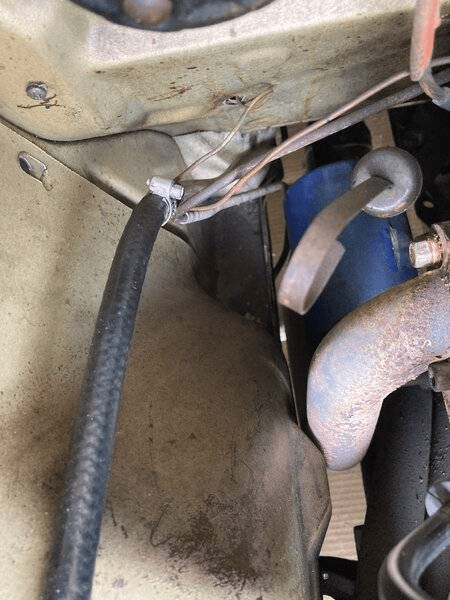

Wire to the temperature sender needs repair. if this breaks and touches ground, the gage can be damaged

Wire to the alternator field needs to be supported. If this gets grounded, the internal fuse in the votlage regulator will melt (if its a mechanical regulator)

Re: Brake lines. Lots of good ideas. The exhaust heat near the lines is not ideal but depending on placement and airflow probaly OK. The areas where its very close seem limited to heat sources. Brake fluid should be good to 300 *F. On the other hand portions of the fuel begins to vaporize at just over 100 F. By 130 F, a significant proportion will be vaporized - espeically winter fuel. Obviously danger of fire is much higher too.

Check out the Master Tech booklets for Disk Brakes and Hydraulics both with a single resevoiur master cylinder and with tandem MC. Master Technician Service Conference - Chrysler's Training for Mechanics

Look under 1966 for the disk hydraulics arrangment with single piston mc, session 219 p. 6

and then the ones in 1967 for the new tandem MC system.

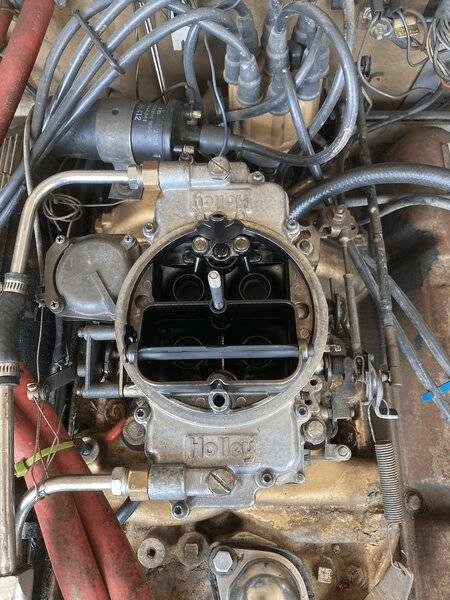

That carb is showing significant reversion.

It's probably running richer than it has to - that's not the cause of the black - that's because reversion sends exhaust back into the combustion chamber.

First. Check fuel levels.

Second. Clean the carb. Make sure the passages are clear of debris, varnish etc. and then map out the restrictions, jets, etc as best you can. There's some old threads on RFS forum about these carbs, and comparing them with their Autolite cousins. It's a decent design and Holley's execution seems to be mostly OK. Its just a lot less common aftermarket carb.

Also just as important, measure and write down the mechanical timing from as low an rpm as you can measure to as high as you feel comfortable. From slow idle to at least 2000 is the imprtant rpms to see what type of curve is in there. With that info, you'll have a baseline and

Pushing more than sucking is usually easier on pumps. On the other hand relocating electric back there is a project.

Looks like the connecting and right side parking brake cables missing

Good news - steel wasn't cut.

If it was me, I'ld look up the specifications on the pump for 1) fuel line connections, 2) electric power draw at X Volts for the range of flow and pressure 3) pressure flow relations and what if any maximum pressure it will create when dead headed (no flow out)

The use of fuel hose and lack of supports for it, and the lack of support for the electric power line are my main safety concerns. If they move around and touch something they will get cut or melted. If the wire vibrates the joints by the connecting terminals will weaken and eventually fail.

Plastic fuel filters were used by the factory and alone don't concern me. But they have to be well supported. Cuorrent location and orientation is OK - in fact close to factory on some engines. Its the lack of support that is concerning. Plastic can melt or get cut even though its a better insulator than steel or aluminum.

Wire to the temperature sender needs repair. if this breaks and touches ground, the gage can be damaged

Wire to the alternator field needs to be supported. If this gets grounded, the internal fuse in the votlage regulator will melt (if its a mechanical regulator)

Re: Brake lines. Lots of good ideas. The exhaust heat near the lines is not ideal but depending on placement and airflow probaly OK. The areas where its very close seem limited to heat sources. Brake fluid should be good to 300 *F. On the other hand portions of the fuel begins to vaporize at just over 100 F. By 130 F, a significant proportion will be vaporized - espeically winter fuel. Obviously danger of fire is much higher too.

Check out the Master Tech booklets for Disk Brakes and Hydraulics both with a single resevoiur master cylinder and with tandem MC. Master Technician Service Conference - Chrysler's Training for Mechanics

Look under 1966 for the disk hydraulics arrangment with single piston mc, session 219 p. 6

and then the ones in 1967 for the new tandem MC system.

That carb is showing significant reversion.

It's probably running richer than it has to - that's not the cause of the black - that's because reversion sends exhaust back into the combustion chamber.

First. Check fuel levels.

Second. Clean the carb. Make sure the passages are clear of debris, varnish etc. and then map out the restrictions, jets, etc as best you can. There's some old threads on RFS forum about these carbs, and comparing them with their Autolite cousins. It's a decent design and Holley's execution seems to be mostly OK. Its just a lot less common aftermarket carb.

Also just as important, measure and write down the mechanical timing from as low an rpm as you can measure to as high as you feel comfortable. From slow idle to at least 2000 is the imprtant rpms to see what type of curve is in there. With that info, you'll have a baseline and