Indy/RHS Heads

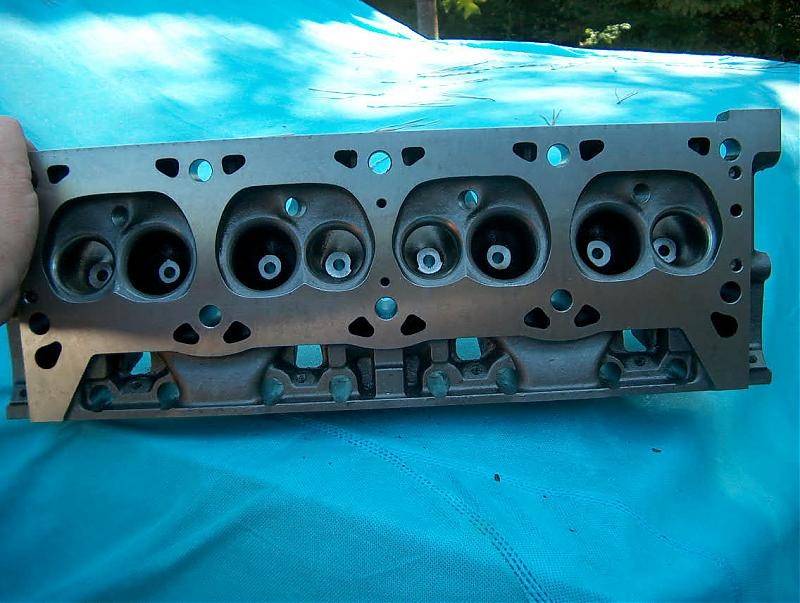

I recieved these heads from RHS, and I must say that I don't get impressed easily. But these recieved my attention. They are some very nice castings, clean and heavy, more so than a stock casted head. The machining on them was very good for production castings. The bowl area is as I figured it would be, very deep. The intake port window is about like a stock casted magnum head, with very little room to grow into.

The port shape is a good design, and has most of the work that generally needs to be done on most other heads is already done or casted with this work in mind. The head cc'd at 171 intake port runner 64 cc exh. runner and 62 cc chamber as recieved. With a stock 1.92 and 1.62 intake and exh. valves from a stock magnum head.

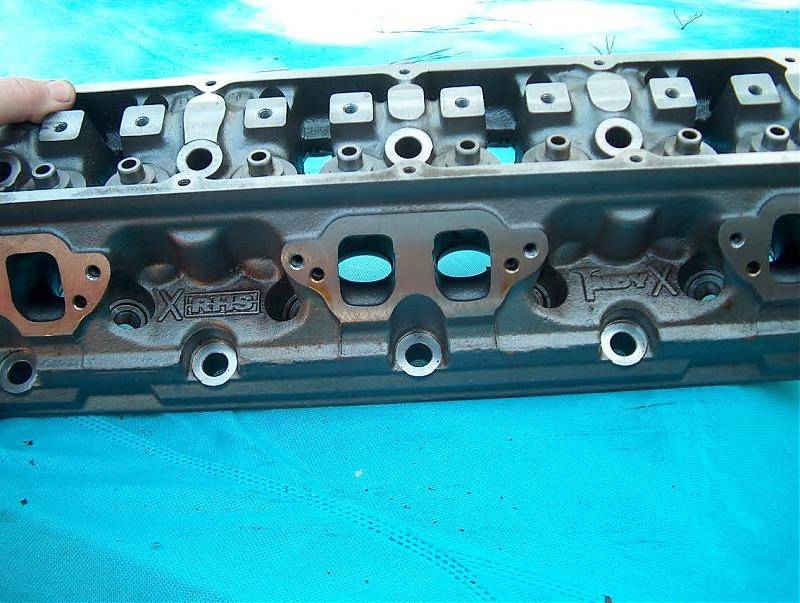

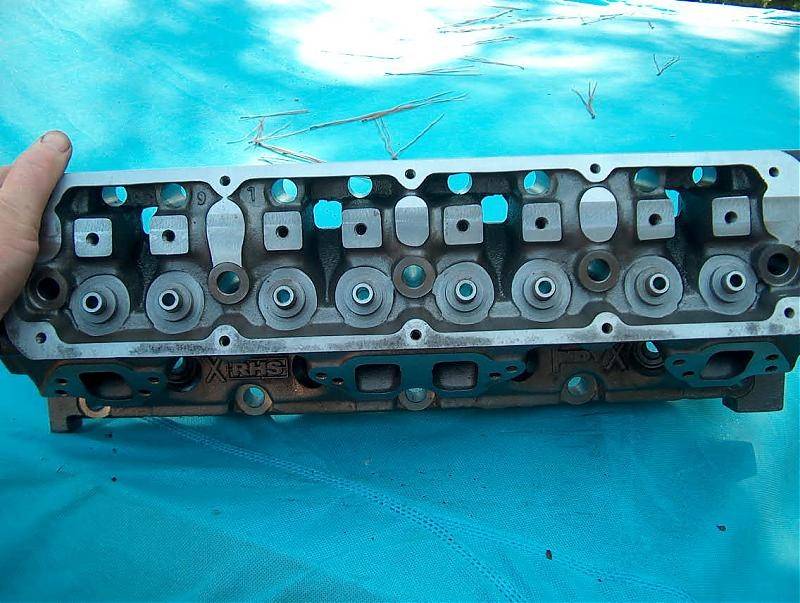

There are a few draw backs that I can see and one of them is the size of the rocker stud that they have for this head. They use a 5/16 thread for the head side and a 3/8 for the rocker side. This seems to be kind of wimpy to me, as the small block chevy's have a problem with breaking these with high lift cams with high durations at .050. The studs are about half the length of the std. stud for the chevy, as you can see in the pictures. There's no room for a stud girdle so it seems that the rocker jam nuts will be close to the top of the stud. IMO I think it really needs to be improved with something beefier, and at least equal to the sbc stuff.

With minor bowl blending and a gasket match as far as I dare go, the heads performed fairly well, and really better than what I expected. But with such a large bowl they really need to be used on a 390 or larger CI engine. These heads are a very good or should be very good performers on engines of this size. The intake port window is or looks really small but it works just fine. I could see doing some moving of the pushrods and running a set of offset rockers and getting flows in the 320-340 range, and port volumes in the 190-200 cc range. Overall these heads would be a very good starting point for most any stroker engine. The selection of valves is rather slim at this time so a change to 11/32 valves should cure this problem. The stock guide size is 8mm so a simple reaming of the guide takes care of this. And now this opens up a good selection of componets to be used.

The spring seat is already 1.550 so cutting the guides down for seals and clearence is about all it needs here. With the bead locks on the factory 8mm valves it has enough clearence for a .550 lift cam without any additional work. But if changing to 11/32 stem valves you will need to get them .150 long as the stock 8mm valves are the same length as the stock sbc valves but the locks are in a different location. This may be able to be cured by using .050 tall locks and .050 taller retainers. The stock installed height is 1.64 with the factory valves, so a longer valve I think would be better than cutting the spring pad down .100 and taking strength out of the heads at this point. Even though I know they say to cut it there and that much.

So from what I see this has to be one of the better flowing heads from a cost effective stand point. I would recommend them, and this is saying alot from me. I personally would rather have a set of these than a set of Eddy's, even though they'er heavier. Any way here are some flow #'s after doing some bowl and gasket work. Keep in mind that this is with the 8mm stem valves so this is going to change with the 11/32 stuff.

lift.............Int...........Exh

.100...........85............82

.200..........138..........130

.300..........212..........193

.400..........243..........204

.500..........289..........205

.600..........296..........205

.700..........293..........205

The exhaust side was just cleaned up from the seat to the guide and the rest was as cast.

I recieved these heads from RHS, and I must say that I don't get impressed easily. But these recieved my attention. They are some very nice castings, clean and heavy, more so than a stock casted head. The machining on them was very good for production castings. The bowl area is as I figured it would be, very deep. The intake port window is about like a stock casted magnum head, with very little room to grow into.

The port shape is a good design, and has most of the work that generally needs to be done on most other heads is already done or casted with this work in mind. The head cc'd at 171 intake port runner 64 cc exh. runner and 62 cc chamber as recieved. With a stock 1.92 and 1.62 intake and exh. valves from a stock magnum head.

There are a few draw backs that I can see and one of them is the size of the rocker stud that they have for this head. They use a 5/16 thread for the head side and a 3/8 for the rocker side. This seems to be kind of wimpy to me, as the small block chevy's have a problem with breaking these with high lift cams with high durations at .050. The studs are about half the length of the std. stud for the chevy, as you can see in the pictures. There's no room for a stud girdle so it seems that the rocker jam nuts will be close to the top of the stud. IMO I think it really needs to be improved with something beefier, and at least equal to the sbc stuff.

With minor bowl blending and a gasket match as far as I dare go, the heads performed fairly well, and really better than what I expected. But with such a large bowl they really need to be used on a 390 or larger CI engine. These heads are a very good or should be very good performers on engines of this size. The intake port window is or looks really small but it works just fine. I could see doing some moving of the pushrods and running a set of offset rockers and getting flows in the 320-340 range, and port volumes in the 190-200 cc range. Overall these heads would be a very good starting point for most any stroker engine. The selection of valves is rather slim at this time so a change to 11/32 valves should cure this problem. The stock guide size is 8mm so a simple reaming of the guide takes care of this. And now this opens up a good selection of componets to be used.

The spring seat is already 1.550 so cutting the guides down for seals and clearence is about all it needs here. With the bead locks on the factory 8mm valves it has enough clearence for a .550 lift cam without any additional work. But if changing to 11/32 stem valves you will need to get them .150 long as the stock 8mm valves are the same length as the stock sbc valves but the locks are in a different location. This may be able to be cured by using .050 tall locks and .050 taller retainers. The stock installed height is 1.64 with the factory valves, so a longer valve I think would be better than cutting the spring pad down .100 and taking strength out of the heads at this point. Even though I know they say to cut it there and that much.

So from what I see this has to be one of the better flowing heads from a cost effective stand point. I would recommend them, and this is saying alot from me. I personally would rather have a set of these than a set of Eddy's, even though they'er heavier. Any way here are some flow #'s after doing some bowl and gasket work. Keep in mind that this is with the 8mm stem valves so this is going to change with the 11/32 stuff.

lift.............Int...........Exh

.100...........85............82

.200..........138..........130

.300..........212..........193

.400..........243..........204

.500..........289..........205

.600..........296..........205

.700..........293..........205

The exhaust side was just cleaned up from the seat to the guide and the rest was as cast.