71autoxr

Well-Known Member

Well after years of spending time in the garage cutting, welding, grinding, fitting, blasting, priming, sanding, painting, cursing and drinking beer.....I finally have some noticeable progress. I have documented the progress along the way. I don't think any of you want to look through the thousands of pictures of minutia so I'll spare those details.

In April 2008 I made my first post and introduced the car and it's story:

http://www.forabodiesonly.com/mopar/showthread.php?t=34153

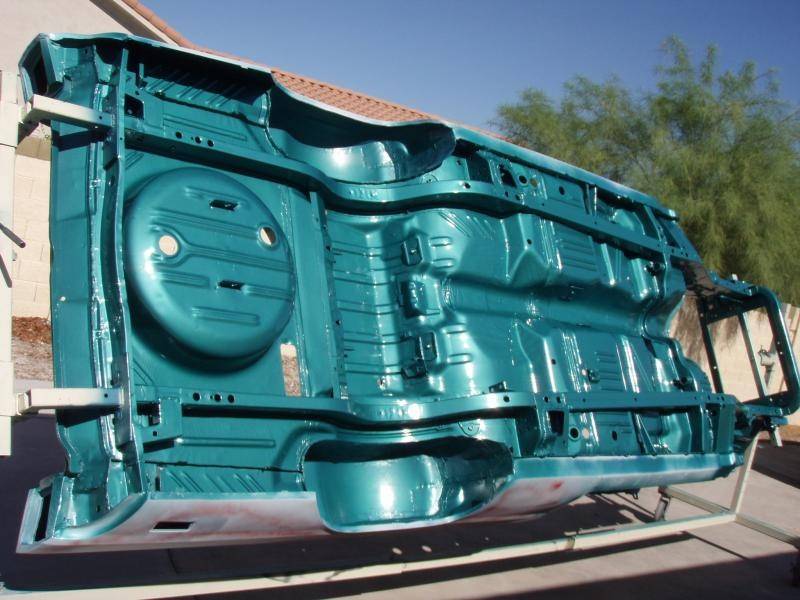

Since the first post I have spent countless hours cutting out all the rust and replacing with sheet metal from the blue rust free dart. The color I decided on is 1969 Q4 Light Turquoise Metallic. The car now has zero rust, no plastic filler and very little poly glaze. I used lead where I could and general hammer and dolly work to straighten each panel. Along the way I added the laser cut to the floor sub-frame connectors, and the XV Motorsports front radiator support. The torque boxes are factory for the convertible. The car went from bare steel to PPG epoxy primer (blue), to PPG K36 primer surfacer (white), and it's final coats of Acrylic Urethane Q4.

Over the years I have collected nearly every part I need to finish it up, save for some parts that are easily scored. Thanks to many FABO members for the deals and the many posts that I have read and learned from over that time. Within the next few weeks the car should come off the rotisserie with a temporary front and rear suspension, have all the body panels put on and aligned, then final paint. I am fortunate to have the space and tools as well as the know how to do everything I have done. It is not the first car I have done. But it sure is the most elaborate work I have ever done along with the most thorough. With the car having been torn apart at the spot welds, nearly every inch has been blasted and put in epoxy primer.

If I have it my way this car will never see anything more formal than a cruise night. From the minute I get the license plate I plan to drive the wheels off of it. It's first road trip will be from AZ to CT in the late summer/fall of 2011 as a tribute to it's rightful owned, John Dolan, who passed away 19 years ago.

As of this past weekend this is what it looks like, along with some along the way photos....

I'll fill a few more posts with interesting photos too.

In April 2008 I made my first post and introduced the car and it's story:

http://www.forabodiesonly.com/mopar/showthread.php?t=34153

Since the first post I have spent countless hours cutting out all the rust and replacing with sheet metal from the blue rust free dart. The color I decided on is 1969 Q4 Light Turquoise Metallic. The car now has zero rust, no plastic filler and very little poly glaze. I used lead where I could and general hammer and dolly work to straighten each panel. Along the way I added the laser cut to the floor sub-frame connectors, and the XV Motorsports front radiator support. The torque boxes are factory for the convertible. The car went from bare steel to PPG epoxy primer (blue), to PPG K36 primer surfacer (white), and it's final coats of Acrylic Urethane Q4.

Over the years I have collected nearly every part I need to finish it up, save for some parts that are easily scored. Thanks to many FABO members for the deals and the many posts that I have read and learned from over that time. Within the next few weeks the car should come off the rotisserie with a temporary front and rear suspension, have all the body panels put on and aligned, then final paint. I am fortunate to have the space and tools as well as the know how to do everything I have done. It is not the first car I have done. But it sure is the most elaborate work I have ever done along with the most thorough. With the car having been torn apart at the spot welds, nearly every inch has been blasted and put in epoxy primer.

If I have it my way this car will never see anything more formal than a cruise night. From the minute I get the license plate I plan to drive the wheels off of it. It's first road trip will be from AZ to CT in the late summer/fall of 2011 as a tribute to it's rightful owned, John Dolan, who passed away 19 years ago.

As of this past weekend this is what it looks like, along with some along the way photos....

I'll fill a few more posts with interesting photos too.