rapidtransitric

LX/LC platform a body swap pioneer

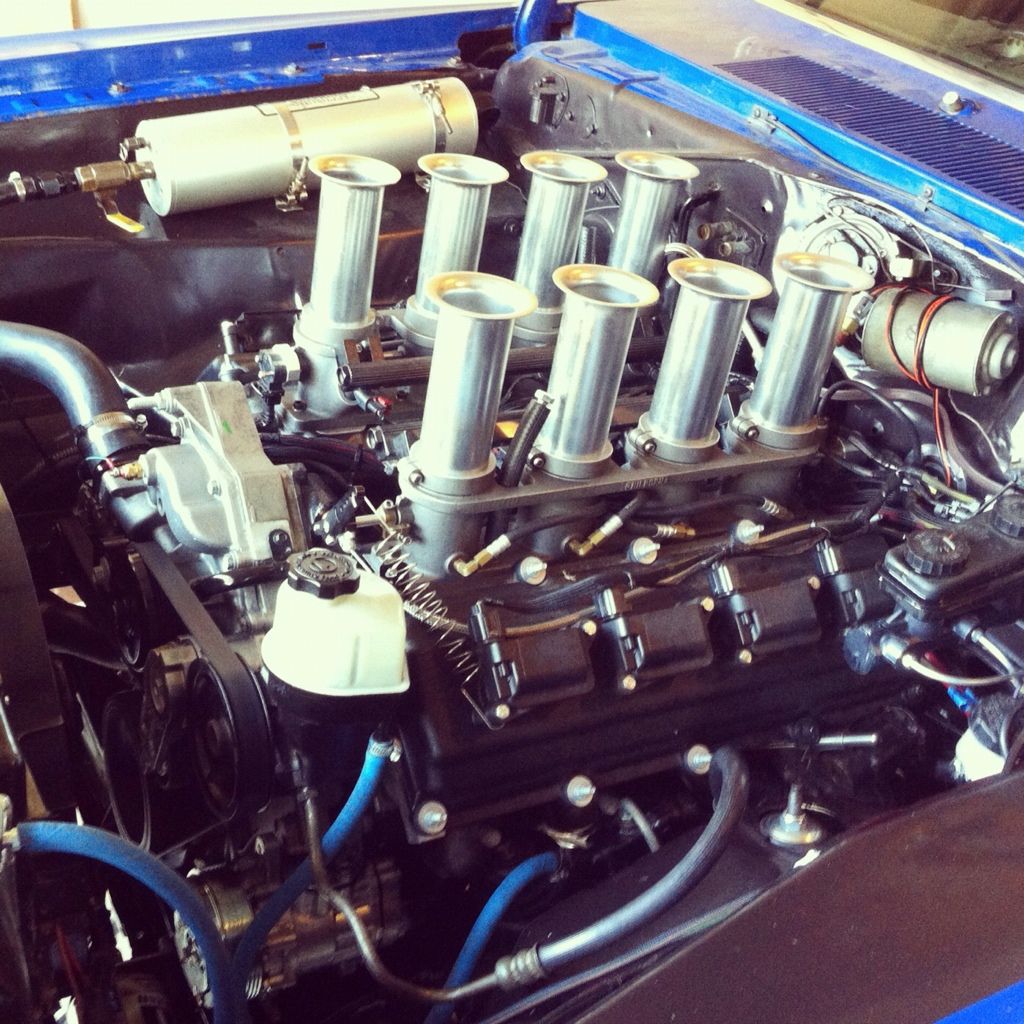

Still need to change the wiper motor to a 3 speed so the hilborn fits, fit exhaust mid pipes, run fuel lines, brake lines, oil cooler/accusump lines, hydraulic clutch lines, radiator hoses, make a top radiator mount, and wire the entire car, including the megasquirt 3x harnesses.

have you got the power steering dialed in with a good fit?