Hi All,

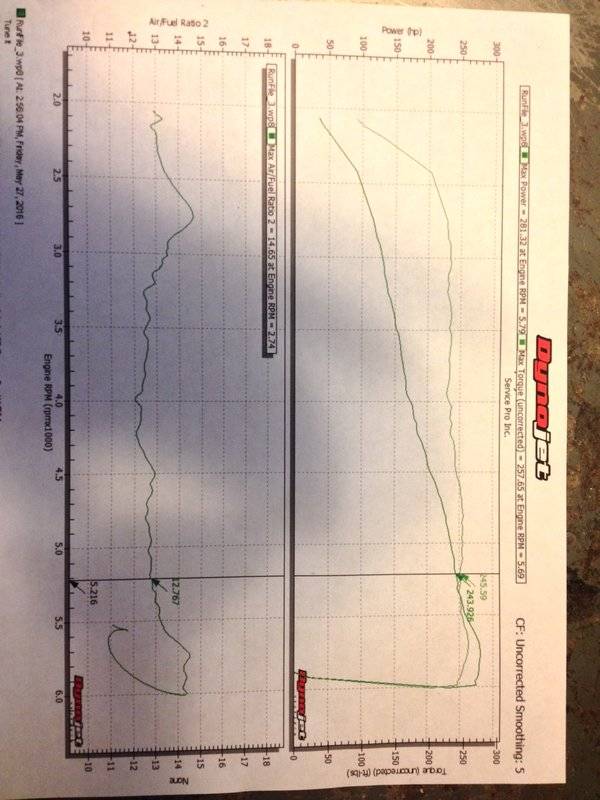

I've got a 318 built to zero deck with forged 1.8 compression height pistons .040 over. Indy RHS heads @62cc's with about 9.5:1 compression. Eddy air gap intake and holly 650 carb. It has a comp XE268H cam and stock rockers. Very noisy valve train...don't like it. I rebuild motors...more like assemble them after machining at my favorite machine shop. I'm not too savy on cam choice. The XE268H has 110* lobe separation and 106* intake centerline. Attached is a dyno sheet of the motor after about 3000 miles.

I would like to increase the torque at a lower rpm, have less overlap so my clothes dont smell like exhaust and I need more vacuum to run my vac assist brakes. a quieter valve train would be nice too...

Any ideas as to a better cam choice. Have about .050 thick head gasket so I can put a thinner one in to raise the compression a bit and take better advantage of the quench area.

I've got a 318 built to zero deck with forged 1.8 compression height pistons .040 over. Indy RHS heads @62cc's with about 9.5:1 compression. Eddy air gap intake and holly 650 carb. It has a comp XE268H cam and stock rockers. Very noisy valve train...don't like it. I rebuild motors...more like assemble them after machining at my favorite machine shop. I'm not too savy on cam choice. The XE268H has 110* lobe separation and 106* intake centerline. Attached is a dyno sheet of the motor after about 3000 miles.

I would like to increase the torque at a lower rpm, have less overlap so my clothes dont smell like exhaust and I need more vacuum to run my vac assist brakes. a quieter valve train would be nice too...

Any ideas as to a better cam choice. Have about .050 thick head gasket so I can put a thinner one in to raise the compression a bit and take better advantage of the quench area.