I don't even use the cork gaskets anymore. If you remove the little pin that holds them in place, which you usually have to do with an aftermarket intake to keep the pin from keeping the intake from sitting all the way down, the cork will slide out of position when you torque the manifold down. The gap is usually pretty small there using aftermarket intakes, so I just run a few beads of RTV at the front and rear of the manifold. Works better.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Father-Son 1974 Duster Project

- Thread starter DusterDaddy

- Start date

-

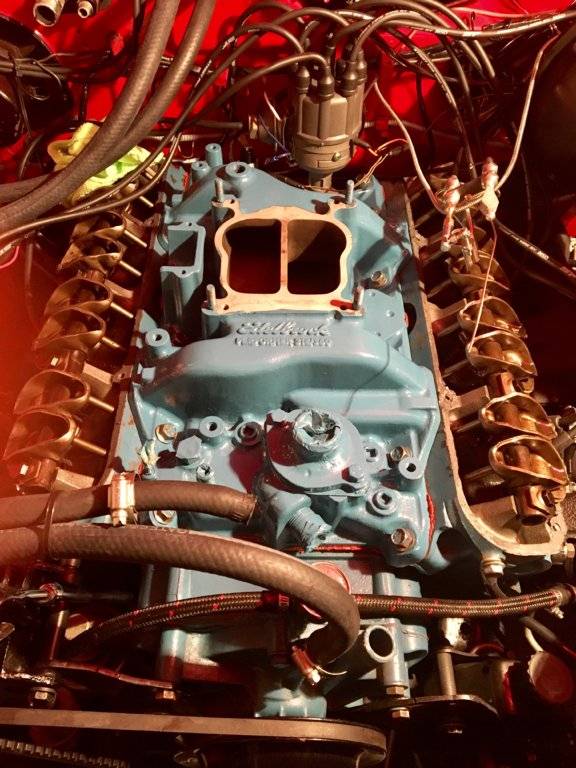

The motor is a fresh build and it hadnt been fired yet when I bought it. It has a performer intake. The seller got it in a swap he did for a guy who bought a nearly complete project Demon but wanted a big block.

He pulled the intake to show that the cam still had assembly lube on it. He just dropped the intake back on and stuck the bolts back in the holes. And I didn't know or check. DAMN IT!!!

Here is a pic when I bought it before I painted the intake....

He pulled the intake to show that the cam still had assembly lube on it. He just dropped the intake back on and stuck the bolts back in the holes. And I didn't know or check. DAMN IT!!!

Here is a pic when I bought it before I painted the intake....

Last edited:

Just put a new gasket on there, it will be fine.

It looks like the dowel pins were removed from the china walls, that is a good thing, because that intake will crack if they are not removed.

It looks like the dowel pins were removed from the china walls, that is a good thing, because that intake will crack if they are not removed.

Just as I suspected. The front and back seals were non existant. After I removed carb and miscilanious, and removed the bolts the intake lifted right off no bond at all from the RTV which confirms it was lifted off and then put back on as I suspected.Just put a new gasket on there, it will be fine.

It looks like the dowel pins were removed from the china walls, that is a good thing, because that intake will crack if they are not removed.

What gaskets are going to be good to use? Only loosened the passenger valve cover to get intake off. Should I get new valve cover gaskets too?

While intake is off I'll redo the oil pressure T I wasn't crazy about. Anyone know where I can get an OEM style connector for the stock oil pressure sender? I used a female spade connector but it does not stay tight. Also need to find the OEM style boot connector for factory temp sensor. I have been using an alligator clip until

I locate one.

While intake is off I'll redo the oil pressure T I wasn't crazy about. Anyone know where I can get an OEM style connector for the stock oil pressure sender? I used a female spade connector but it does not stay tight. Also need to find the OEM style boot connector for factory temp sensor. I have been using an alligator clip until

I locate one.

Last edited:

Just squeeze the spade connector to make it tighter.

Use a ring connector on the temp with a machine nut.

Use a ring connector on the temp with a machine nut.

Pardon my ignorance but what is the center port on each side of the intake for? should I put RTV on both sides of the gasket like they had it or only on the ends and around the water jacket ports?

The center ports are for the exhaust heat crossover to make the oem choke work.

Another question. What is a good way to remove the remains of the old valve cover gaskets so the bits and pieces won't fall into the heads where the valve springs are?

the gaskets came off pretty well, but some material was left behind on the heads here and there. I am planning on being super careful but there must be some trick...

the gaskets came off pretty well, but some material was left behind on the heads here and there. I am planning on being super careful but there must be some trick...

Put rags in/over... Shop vac as you scrape.Another question. What is a good way to remove the remains of the old valve cover gaskets so the bits and pieces won't fall into the heads where the valve springs are?

the gaskets came off pretty well, but some material was left behind on the heads here and there. I am planning on being super careful but there must be some trick...

View attachment 1715095169

OEM is body color with no paint on the bottom side, here is a set of originals I dug out of my stash.I have the support braces. Just need to figure out what color they should be. This guy did his in black. I am modeling my bay after this one.

View attachment 1715093026

OK

1. Just glanced at the new Felpro gaskets. Do the raised stampings face the intake or the head? If they only go one way sorry for asking a stupid question. I know to use RTV only on the front and back of the manifold and to go around the water jacket ports with RTV on both sides of the port hole in the gasket.

2. Should I use RTV on both sides of the gasket around the center crossover ports as it was done on the original install of this manifold?

3. When all back together, what should I set the initial timing for with the advance unplugged from vacuum? (I know I asked this before...)

While I can get at things I will be reworking the tee I installed for oil pressure senders ( stock light and gauge )

I will also be installing a tee in the vacuum port of the manifold for power brakes and heat/ac vacuum stuff.

1. Just glanced at the new Felpro gaskets. Do the raised stampings face the intake or the head? If they only go one way sorry for asking a stupid question. I know to use RTV only on the front and back of the manifold and to go around the water jacket ports with RTV on both sides of the port hole in the gasket.

2. Should I use RTV on both sides of the gasket around the center crossover ports as it was done on the original install of this manifold?

3. When all back together, what should I set the initial timing for with the advance unplugged from vacuum? (I know I asked this before...)

While I can get at things I will be reworking the tee I installed for oil pressure senders ( stock light and gauge )

I will also be installing a tee in the vacuum port of the manifold for power brakes and heat/ac vacuum stuff.

Last edited:

The raised bead goes against the head, and the manifold to head gaskets go on first-run your bead around the water jacket ports and then lay them in place. I use the cork gaskets for the manifold to block, but they must be the peel and stick type. Make sure the surfaces are clean and dry and stick them down carefully. Apply a dab of rtv to the four corners where the gaskets meet and run a bead around each water passages this time on the gasket surface. Then line up and lay that manifold on straight and careful.

The cork pieces that came with my set are not self stick. 3M Spray 90 is single or 2 surface adhesive that I can use to keep the cork in place during manifold install. Same type of glue as double face tape etc. Just a spritz will do the job. What do you think @TF360 ?The raised bead goes against the head, and the manifold to head gaskets go on first-run your bead around the water jacket ports and then lay them in place. I use the cork gaskets for the manifold to block, but they must be the peel and stick type. Make sure the surfaces are clean and dry and stick them down carefully. Apply a dab of rtv to the four corners where the gaskets meet and run a bead around each water passages this time on the gasket surface. Then line up and lay that manifold on straight and careful.

bkd

No more Scoops

Yes, I have a mopar friend that does this and he has never had problems using that.

While intake was off I reworked the tee for oil pressure gauges. Had a long nipple off the block and even though the sender for the oil light was on the side of the tee and the tubing to the gauge came off the top the vac advance came really close. This way everything is closer to the block and there is plenty of clearance

Got the manifold back on. Put a fresh coat of paint on while it was off. I used the cork seals on the front and back and the Spray 90 worked good. Used red RTV in a caulk tube for the corners, water ports and on top of the cork.

Didn't have a provision for vacuum to run the heat and AC actuators. Put in this tee to solve that and it eliminates a 90* bend in the tubing to the brake booster.

So even though I didn't want to deal with taking this all apart to reinstall a gasket, I did make some small but needed improvements along the way.

Got the manifold back on. Put a fresh coat of paint on while it was off. I used the cork seals on the front and back and the Spray 90 worked good. Used red RTV in a caulk tube for the corners, water ports and on top of the cork.

Didn't have a provision for vacuum to run the heat and AC actuators. Put in this tee to solve that and it eliminates a 90* bend in the tubing to the brake booster.

So even though I didn't want to deal with taking this all apart to reinstall a gasket, I did make some small but needed improvements along the way.

For some ridiculous reason, I cant find wire looms that will work with the posts on my stock valve covers. Any tips where to get some?

Theres this website I know that has a parts wanted area, you might try there, its called...

Sorry, had to

Honestly, I never thought to ask in the want ads! Gunna do it now.Sorry, had to

Taking part of a day off to help my son drag his old W150 to upstate New York tomorrow.

He traded it for a 73 Javelin. He has the Silverado now so he figured he could let the old Dodge go...

He traded it for a 73 Javelin. He has the Silverado now so he figured he could let the old Dodge go...

Last edited:

Duh! Posted in parts wanted and my OEM wire looms are on the way!Honestly, I never thought to ask in the want ads! Gunna do it now.

Hoping I can get everything reassembled on Sunday. Mama has a honey do list for me tomorrow...

-