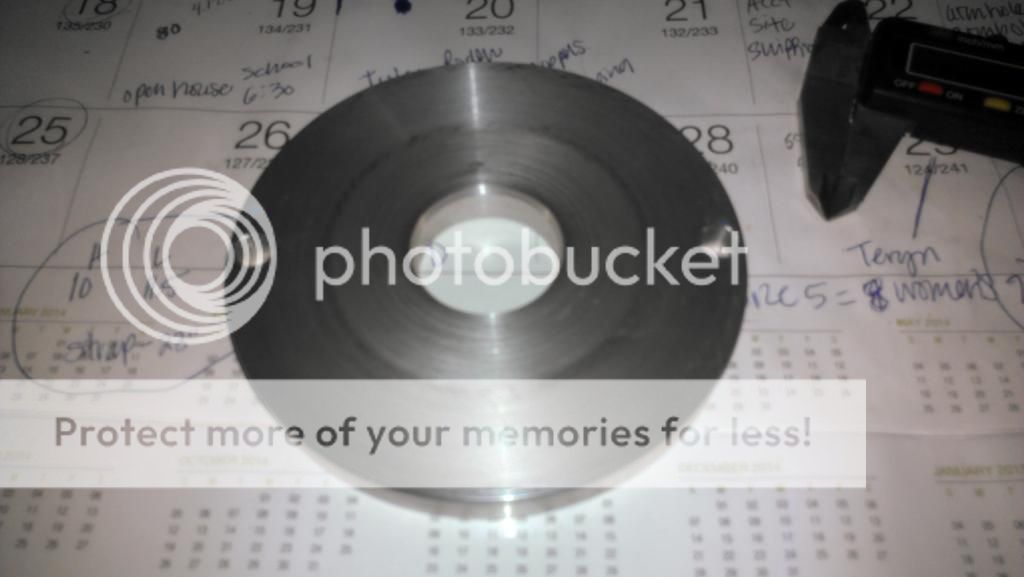

If you need to back up the Trans a half inch, use a scollop ring spacer instead of cutting the input shaft. Unless that puts your shifter out of place. I did that on my ford for both the v6 and big block. I got my set-up from McLeod. However, you could get a piece of .5" aluminum plate and cut a ring and drill to match the clutch adapter (Trans front) and fit between the bell adapter and clutch adapter with a set of long pins.

Have to say, I haven't done any research on available parts since I got mine figured out. But if you go to McLeod Racing site under bell housings and click on one of the sets it will enlarge enough to see the ring I'm talking about.

I was looking at a Magnum XL which is the new HD Trans for the new 'Stangs, to replace the OEM Getrag that won't handle the high HP. As it is configured like the LS1 with the shifter all the way back on top of the tail shaft. But, they are many$ and come as a complete kit, out of which I only needed the tranny.

Good luck,

MikeH

Have to say, I haven't done any research on available parts since I got mine figured out. But if you go to McLeod Racing site under bell housings and click on one of the sets it will enlarge enough to see the ring I'm talking about.

I was looking at a Magnum XL which is the new HD Trans for the new 'Stangs, to replace the OEM Getrag that won't handle the high HP. As it is configured like the LS1 with the shifter all the way back on top of the tail shaft. But, they are many$ and come as a complete kit, out of which I only needed the tranny.

Good luck,

MikeH