rmchrgr

Skate And Destroy

I bought my '71 Duster in the spring of 2012. I sold a few cars and parts to have enough funds to get it. I wanted a rust-free car and this was one is. When I started looking, I thought I wanted a good starting point for a project that I would build myself but ended up buying a good running car. It was a good choice. The previous owner said the car went a best of 11.97 but was normally a 12.0-12.1 car. That was good enough for me since that was my intended performance goal.

I bought the car from someone on here. I noticed it when it was first put up for sale but didn't think it was for me at the time. I kept re reading it though and the more I looked at the ad, the more I started to realize it was exactly what I had been looking for. The cars I had sold prior to buying this one were impulse buys ('65 Valiant, '71 Dart) that I regretted. I'd buy them, start messing with them, lose interest and sell at a loss. My wife thought I was crazy (what else is new) and was very wary (what else is new) when I told her I was looking at another one. Really though, I wanted a Duster and not a Dart or Valiant. Took me a while to figure that out. I even bought and sold a '70 Duster in between that I didn't do anything with. The only things I did with that one were pulling it in to the garage and out when I sold it. Finally though I was in the right place at the right time and fortunate enough to be able to buy it. I pulled the trigger and did the deal.

Its mostly built the way I would have done it myself - W2 340 with a solid cam, 750 DP, Victor W2 intake, TTi 1 7/8 headers which runs on a mix of pump 93 and Cam 2 100 unleaded when I can get it. Drivetrain consists of a low gear, forward pattern 904 with a B&M Pro Ratchet and 4.30 gears. Chassis is your basic street/strip setup - skinny front wheels and 275 drag radials on the back, offset shackles, S/S springs, frame connectors, battery in the trunk, CE shocks. The car still retained the OE drum brakes all around. Manual steering.

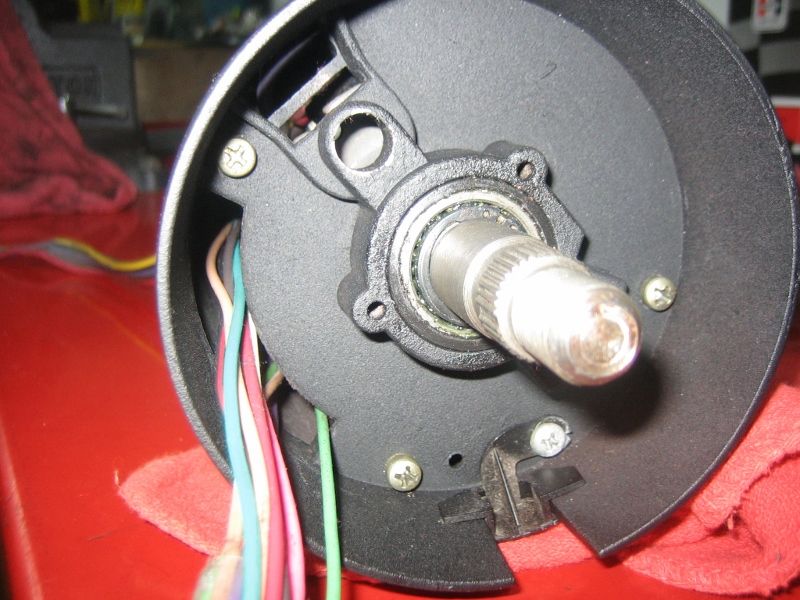

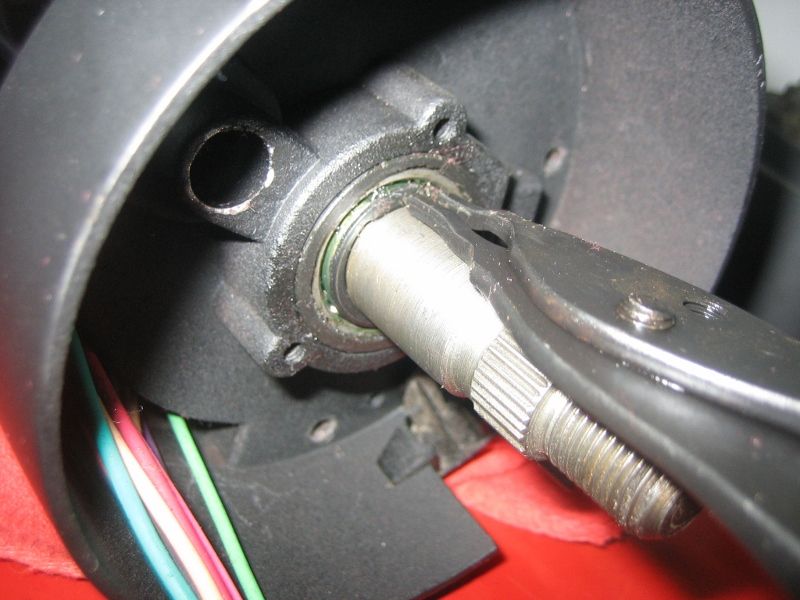

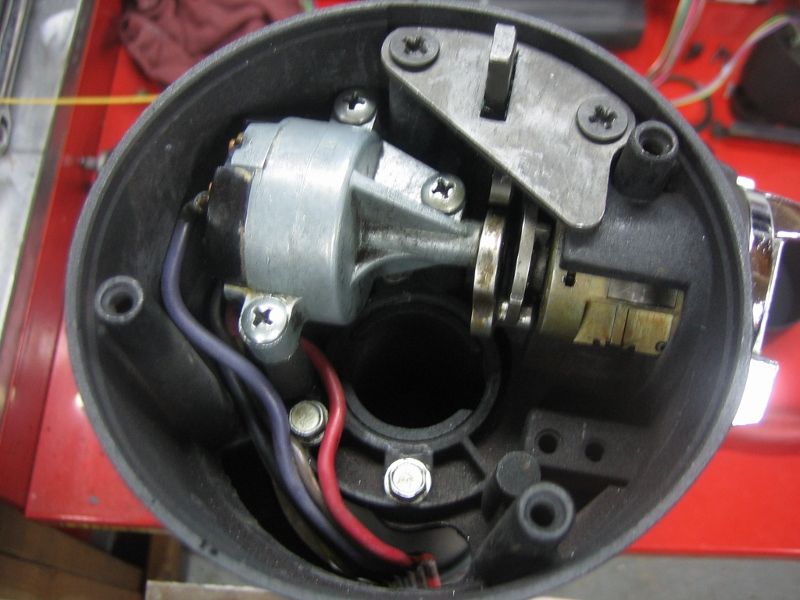

Interior is original but in very nice condition. Black vinyl bench with low end trim. AM radio, heater but no A/C. All the glass is good, door panels are good, trim is a little worn but not trashed. The column still had the column shift parts on it and the basic steering wheel. The carpet was passable but had a hole in it. Cheapo Auto Gauge gauges and tach. Pretty sure it was built in the early 90s and stayed that way.

I drove it for most of last year up until about December. It was really fun to drive on the street. I took it out for many blasts down a back road near my house and it feels really quick. I've never had a car that shifts at 7K - its hard to describe what that feels like if you don't know but the first time I did it, I knew I was home. Took it to a few cruise ins and didn't get a lot of attention. Its kind of a sleeper I think even though it has Centerline Auto Drags and drag radials. My 2nd kid was born last May so I was a little busy and never got to take it down the track.

The more I drove it, the more I began to realize that there was a lot of stuff that was worn out. The front end was shot and almost every bushing was disintegrated. The drum brakes were shot. The fuel system was working but was not installed very cleanly and the fuel pressure was high. The 4.30 gears were a little too much. And on and on.

Besides those things, I've had an ongoing vision for whatever cars I've had over the years - stripped down, light and simple. No extra gee gaws, creature comforts or flashy stuff. Made to go but not ratty or gutted and somewhat 'factory correct'. So that means the accessories got the ax - radio, heater stuff, bench seat etc. I managed to find all the correct delete plates and parts to cover up the vacant spots - heater, radio, blower motor. I even found two (yes, two) super-rare driver's side heater delete fresh air vent boxes. No fiberglass body parts. Got rid of the heavy steel bumper brackets in front and replaced those with a very light set of aluminum ones I got from a Moparts member.

So basically what I'm saying here is that I got a good car which I'm trying to put my own stamp on. So far, I've changed a lot of stuff but stopped short of completely disassembling the car. It doesn't really need any body work so all the upgrades are mechanical and/or performance related.

I've been involved in the hobby for a while but not at the level I'm at now. Being a Chrysler dealer tech for several years has given me the skills and the confidence to tackle most of the older car stuff with ease. I have basically all the tools and equipment I need at home. As a side note, my shop has also come together which is something I never had before I bought my house in 2009. No more working in the street in Brooklyn, NY or at my dads house an hour away.

At this point, the car has been down since January. I had hoped to finished with this stuff but due to some unforseen circumstances, I have not had as much time to work on it as I would have liked. The hope though is to be driving it again before the end of the summer. I managed to re-do the fuel system and get it running again before I took it apart but I will try to include some of that here as well.

So on to the pics. I'll try to break it down into sections and update stuff as it gets completed. Thanks for looking.

Here's how it looked when I first got it.

More to come! Thanks for looking.

I bought the car from someone on here. I noticed it when it was first put up for sale but didn't think it was for me at the time. I kept re reading it though and the more I looked at the ad, the more I started to realize it was exactly what I had been looking for. The cars I had sold prior to buying this one were impulse buys ('65 Valiant, '71 Dart) that I regretted. I'd buy them, start messing with them, lose interest and sell at a loss. My wife thought I was crazy (what else is new) and was very wary (what else is new) when I told her I was looking at another one. Really though, I wanted a Duster and not a Dart or Valiant. Took me a while to figure that out. I even bought and sold a '70 Duster in between that I didn't do anything with. The only things I did with that one were pulling it in to the garage and out when I sold it. Finally though I was in the right place at the right time and fortunate enough to be able to buy it. I pulled the trigger and did the deal.

Its mostly built the way I would have done it myself - W2 340 with a solid cam, 750 DP, Victor W2 intake, TTi 1 7/8 headers which runs on a mix of pump 93 and Cam 2 100 unleaded when I can get it. Drivetrain consists of a low gear, forward pattern 904 with a B&M Pro Ratchet and 4.30 gears. Chassis is your basic street/strip setup - skinny front wheels and 275 drag radials on the back, offset shackles, S/S springs, frame connectors, battery in the trunk, CE shocks. The car still retained the OE drum brakes all around. Manual steering.

Interior is original but in very nice condition. Black vinyl bench with low end trim. AM radio, heater but no A/C. All the glass is good, door panels are good, trim is a little worn but not trashed. The column still had the column shift parts on it and the basic steering wheel. The carpet was passable but had a hole in it. Cheapo Auto Gauge gauges and tach. Pretty sure it was built in the early 90s and stayed that way.

I drove it for most of last year up until about December. It was really fun to drive on the street. I took it out for many blasts down a back road near my house and it feels really quick. I've never had a car that shifts at 7K - its hard to describe what that feels like if you don't know but the first time I did it, I knew I was home. Took it to a few cruise ins and didn't get a lot of attention. Its kind of a sleeper I think even though it has Centerline Auto Drags and drag radials. My 2nd kid was born last May so I was a little busy and never got to take it down the track.

The more I drove it, the more I began to realize that there was a lot of stuff that was worn out. The front end was shot and almost every bushing was disintegrated. The drum brakes were shot. The fuel system was working but was not installed very cleanly and the fuel pressure was high. The 4.30 gears were a little too much. And on and on.

Besides those things, I've had an ongoing vision for whatever cars I've had over the years - stripped down, light and simple. No extra gee gaws, creature comforts or flashy stuff. Made to go but not ratty or gutted and somewhat 'factory correct'. So that means the accessories got the ax - radio, heater stuff, bench seat etc. I managed to find all the correct delete plates and parts to cover up the vacant spots - heater, radio, blower motor. I even found two (yes, two) super-rare driver's side heater delete fresh air vent boxes. No fiberglass body parts. Got rid of the heavy steel bumper brackets in front and replaced those with a very light set of aluminum ones I got from a Moparts member.

So basically what I'm saying here is that I got a good car which I'm trying to put my own stamp on. So far, I've changed a lot of stuff but stopped short of completely disassembling the car. It doesn't really need any body work so all the upgrades are mechanical and/or performance related.

I've been involved in the hobby for a while but not at the level I'm at now. Being a Chrysler dealer tech for several years has given me the skills and the confidence to tackle most of the older car stuff with ease. I have basically all the tools and equipment I need at home. As a side note, my shop has also come together which is something I never had before I bought my house in 2009. No more working in the street in Brooklyn, NY or at my dads house an hour away.

At this point, the car has been down since January. I had hoped to finished with this stuff but due to some unforseen circumstances, I have not had as much time to work on it as I would have liked. The hope though is to be driving it again before the end of the summer. I managed to re-do the fuel system and get it running again before I took it apart but I will try to include some of that here as well.

So on to the pics. I'll try to break it down into sections and update stuff as it gets completed. Thanks for looking.

Here's how it looked when I first got it.

More to come! Thanks for looking.