I have a Champion 4 core 228221; radiator that has performed well in my new 416 stroker small block. I've put 3458 miles on the motor in 1 ½ years and driven a few times 80 miles @3700rpm to/from Willow Springs Raceway racing 60 laps/150 miles going about 130 mph @ 5800 rpm on straights. Radiator looks great inside, no rust, and no measured electrolysis. I run distilled water and Justice Brothers Radiator Cooler (RC/22P) and Justice Brothers Cooling System Protector ( CSP/1P). No major cooling problems, but I don't run a fan shroud.

Once in 88 degree heat I got stuck in road construction barely moving for 20 minutes. Motor got up to 215 degrees. The fan by itself just could not pull enough air without the car moving. Time for a shroud.

When we first built the motor, the Champion upper radiator hose mounted way too close to the center and hit my 5 blade MP fan kit. So I cut off each blade of a 5 blade and made a fan. The car still performed pretty darn good with a skimpy looking fan and no shroud. I run the short Jaguar fan clutch (Hayden #2765) because of the thick radiator and 70-up taller aluminum water pump.

The upper hose inlet tube had to be moved outward to fit any fan shroud. Radiator Works in Northridge, Ca did that and added a aluminum tab on top to help attach a shroud.

The factory 68-69 and 70-72 V-8 shrouds needed cutting to end up with a marginal shroud. So I traded some parts with Troy and he said he'd make me a shroud if I helped.

Here's the pictures that tell the story.

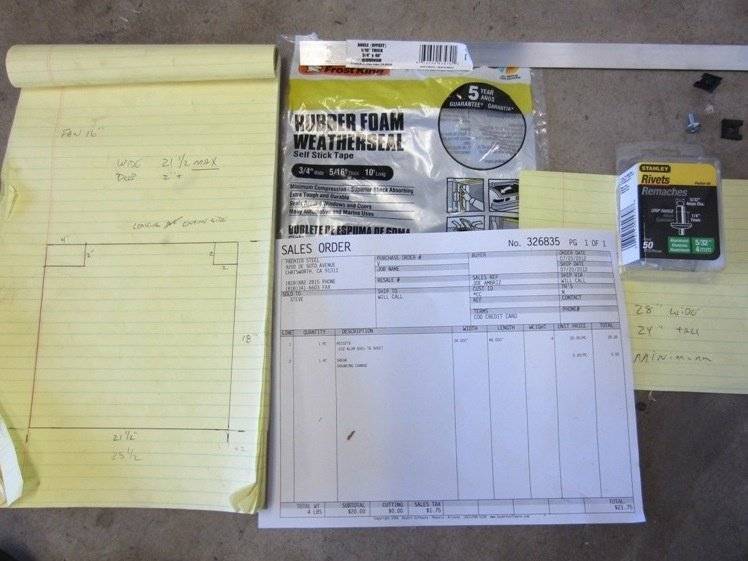

That aluminum angle is 1/16" thick and 3/4" by 1/2". 48" long piece. The 20 gauge aluminum sheet was $21.75 for a 24" x 48" piece.

-

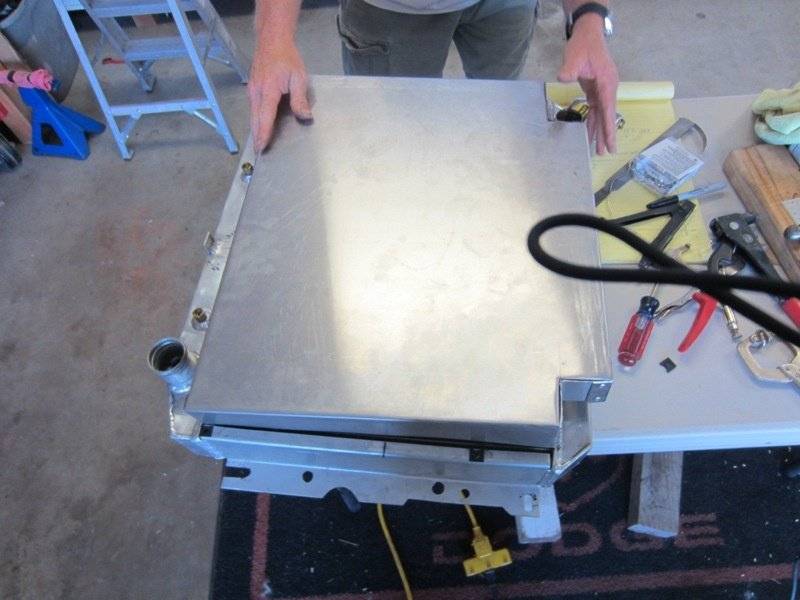

We put these on the existing Champion holes. But the aluminum was too thick for them even after I bent them out some. So we thinned the aluminum out some and also made the shroud end rails fit more flush.

When the radiator was still in the car I marked the centerline of the water pump translated to the radiator itself. This way we would know where to start the center of the fan shroud opening later. I also had the upper shroud tab welded onto the radiator along this centerline.

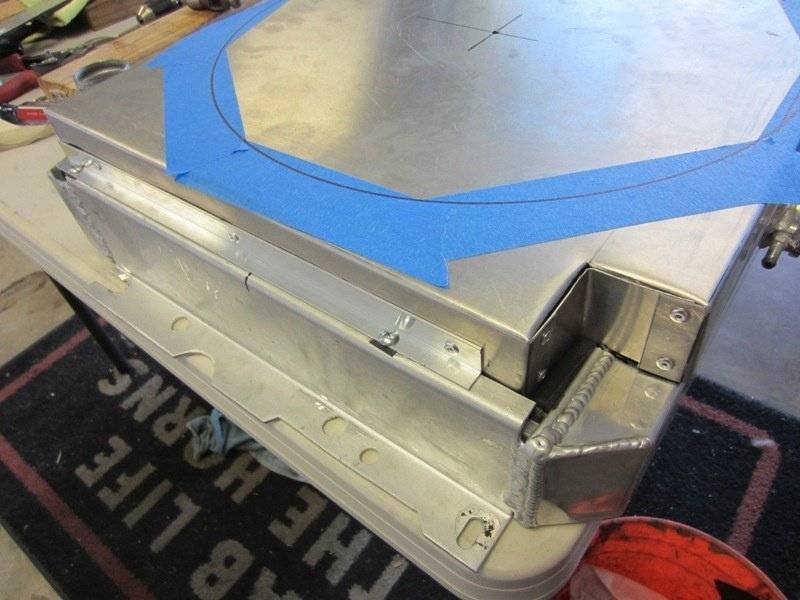

We added foam to make a tight seal and to protect the shroud from rubbing into the radiator tubes/fins.

Foam detail

Side rail angles not installed yet.

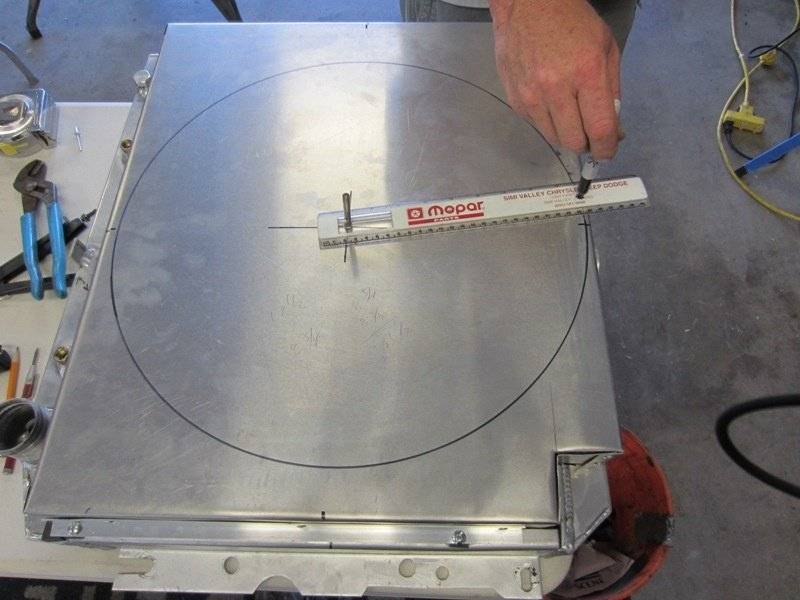

The optimum hole diameter for shroud take the fan diameter and add 10% of the fan diameter. So for my 16" fan I added 1.6" to 16" and cut my hole at 17.6".

The optimum depth of the shroud is when the pitch of the fan blades are showing 1/2 in and 1/2 out of the shroud.

That info came from a past employee of a large automobile and industrial radiator manufacture explained to me the design of a fan shroud.

Troy cut the hole with a handheld jigsaw. The tape is so the aluminum doesn't get all scratched up from the jigsaw bouncing on it. I have a little hand held notcher. Neat, but would have taken me forever to cut something this large.

Here's the detail of the foam on the bottom of the shroud.

I wanted a durable finish on the shroud that didn't need the maintenance of bare aluminum. So I painted it VHT wrinkle paint baked in an oven. I can run my fingernail against this paint enough to file it and it will not scratch.

The fan for my system is very small. Like I said before it's a MP 5 blade fan cut down 1" so it would clear the inlet tube and be lower than the top of the radiator (don't cut my fingers off). This was done 1 1/2 years and 3458 miles ago.

The 1" cut really takes a lot of meat off the fan. Five 1" cuts stacked on the right next to the C-clamp pictured below. I'm really shocked it cooled so well without the fan shroud. I guess I could say it's low drag for increased horsepower.

Here's the anorexic looking fan mocked up with freshly painted shroud.

This shows the idea of the fan blade being 1/2 in and 1/2 out of the shroud

Here's a picture of the fan shroud installed.

The JAZ over flow bottle on the right has a valve so you can drain it when and where you want. Not that its ever had anything overflow into it of significance.

I refilled the radiator with distilled water and Justice Brothers Radiator Cooler (RC/22P) and Justice Brothers Cooling System Protector ( CSP/1P) to give me the best cooling and resistance to electrolysis.

So I got it all together and tested it. It was 92 degrees in my garage when I started it up.

I figure if I went this far, I was really going to test it. I've been a S-O-B to this car for 19 years, why should I stop now ....

I let it idle for 25 minutes not moving it an inch in the garage!

The front of the car was 1 1/2 ft from my washer and dryer. So no wind to help it. Even with an open garage door, after 25 minutes my eyes would tear up if I stayed in there too long and the car raised the temp in the whole garage to 98 degrees.

1) After 10 minutes idling, temp measured on heat gun was 160 deg. at the temp sender.

2) After 25 minutes idling, temp measured on heat gun was only 203 deg. at the temp sender. Turned it off and no boilover whatsoever. I didn't think that was bad given the extreme abuse. It was a fricken nauseous sauna in there.

I think it did really well for such an extreme test!

Here's a picture showing the suction of a paper towel on my grille at idle and the ambient temperature there.

Once in 88 degree heat I got stuck in road construction barely moving for 20 minutes. Motor got up to 215 degrees. The fan by itself just could not pull enough air without the car moving. Time for a shroud.

When we first built the motor, the Champion upper radiator hose mounted way too close to the center and hit my 5 blade MP fan kit. So I cut off each blade of a 5 blade and made a fan. The car still performed pretty darn good with a skimpy looking fan and no shroud. I run the short Jaguar fan clutch (Hayden #2765) because of the thick radiator and 70-up taller aluminum water pump.

The upper hose inlet tube had to be moved outward to fit any fan shroud. Radiator Works in Northridge, Ca did that and added a aluminum tab on top to help attach a shroud.

The factory 68-69 and 70-72 V-8 shrouds needed cutting to end up with a marginal shroud. So I traded some parts with Troy and he said he'd make me a shroud if I helped.

Here's the pictures that tell the story.

That aluminum angle is 1/16" thick and 3/4" by 1/2". 48" long piece. The 20 gauge aluminum sheet was $21.75 for a 24" x 48" piece.

-

We put these on the existing Champion holes. But the aluminum was too thick for them even after I bent them out some. So we thinned the aluminum out some and also made the shroud end rails fit more flush.

When the radiator was still in the car I marked the centerline of the water pump translated to the radiator itself. This way we would know where to start the center of the fan shroud opening later. I also had the upper shroud tab welded onto the radiator along this centerline.

We added foam to make a tight seal and to protect the shroud from rubbing into the radiator tubes/fins.

Foam detail

Side rail angles not installed yet.

The optimum hole diameter for shroud take the fan diameter and add 10% of the fan diameter. So for my 16" fan I added 1.6" to 16" and cut my hole at 17.6".

The optimum depth of the shroud is when the pitch of the fan blades are showing 1/2 in and 1/2 out of the shroud.

That info came from a past employee of a large automobile and industrial radiator manufacture explained to me the design of a fan shroud.

Troy cut the hole with a handheld jigsaw. The tape is so the aluminum doesn't get all scratched up from the jigsaw bouncing on it. I have a little hand held notcher. Neat, but would have taken me forever to cut something this large.

Here's the detail of the foam on the bottom of the shroud.

I wanted a durable finish on the shroud that didn't need the maintenance of bare aluminum. So I painted it VHT wrinkle paint baked in an oven. I can run my fingernail against this paint enough to file it and it will not scratch.

The fan for my system is very small. Like I said before it's a MP 5 blade fan cut down 1" so it would clear the inlet tube and be lower than the top of the radiator (don't cut my fingers off). This was done 1 1/2 years and 3458 miles ago.

The 1" cut really takes a lot of meat off the fan. Five 1" cuts stacked on the right next to the C-clamp pictured below. I'm really shocked it cooled so well without the fan shroud. I guess I could say it's low drag for increased horsepower.

Here's the anorexic looking fan mocked up with freshly painted shroud.

This shows the idea of the fan blade being 1/2 in and 1/2 out of the shroud

Here's a picture of the fan shroud installed.

The JAZ over flow bottle on the right has a valve so you can drain it when and where you want. Not that its ever had anything overflow into it of significance.

I refilled the radiator with distilled water and Justice Brothers Radiator Cooler (RC/22P) and Justice Brothers Cooling System Protector ( CSP/1P) to give me the best cooling and resistance to electrolysis.

So I got it all together and tested it. It was 92 degrees in my garage when I started it up.

I figure if I went this far, I was really going to test it. I've been a S-O-B to this car for 19 years, why should I stop now ....

I let it idle for 25 minutes not moving it an inch in the garage!

The front of the car was 1 1/2 ft from my washer and dryer. So no wind to help it. Even with an open garage door, after 25 minutes my eyes would tear up if I stayed in there too long and the car raised the temp in the whole garage to 98 degrees.

1) After 10 minutes idling, temp measured on heat gun was 160 deg. at the temp sender.

2) After 25 minutes idling, temp measured on heat gun was only 203 deg. at the temp sender. Turned it off and no boilover whatsoever. I didn't think that was bad given the extreme abuse. It was a fricken nauseous sauna in there.

I think it did really well for such an extreme test!

Here's a picture showing the suction of a paper towel on my grille at idle and the ambient temperature there.