Did a leak down test on the 273 today and took some pics on how I did it for the next guy that searches it. Please add any , corrections, advice, or tips.

1. Find Top Dead Center on Piston #1. I used a piston stop to make sure the balancer hadn't shifted.

Using a small level I made horizontal and vertical marks:

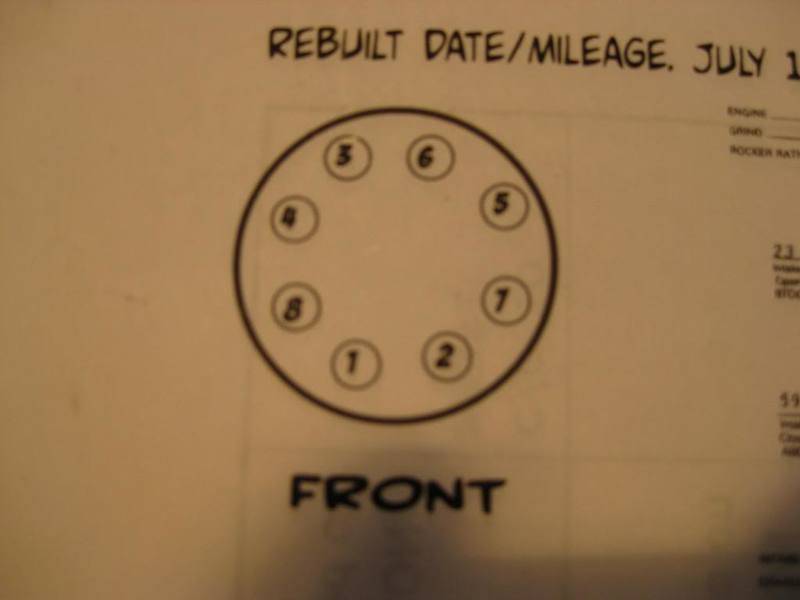

Each 1/4 turn of the crank will put the next cylinder in the firing order at top dead center. Firing Order: 1 8 4 3 6 5 7 2

Next I checked the gap (solid, non hydraulic lifters) to make sure the valves were fully closed. I could also just remove the rocker arms completely.

Then I used the piston stop on the cylinder opposite the firing order to prevent the crank from turning under the air pressure. Opposite pistons: 1:6, 2:3, 4:7, 5:8

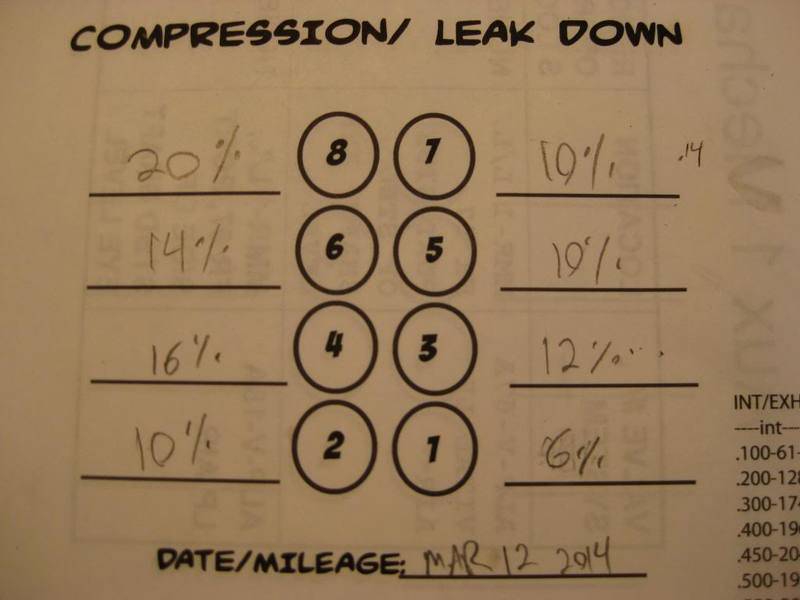

Then Applied 100PSI to get the first reading. Number 8 cylinder is losing 20%.

Then I put the spark plugs into the neighboring cylinders to help rule out a head gasket breach between cylinders.

Next I use a piece of hose to my ear and listen to locate where the 20% of air is going to.

Carb: Intake Valve

Exhaust:Exhaust Valve

Dip Stick (Crankcase): Past the piston rings (Normal)

Radiator: Cracked head or cylinder wall.

I wrote down all the results:

Might be time for a rebuild, what do you think?

1. Find Top Dead Center on Piston #1. I used a piston stop to make sure the balancer hadn't shifted.

Using a small level I made horizontal and vertical marks:

Each 1/4 turn of the crank will put the next cylinder in the firing order at top dead center. Firing Order: 1 8 4 3 6 5 7 2

Next I checked the gap (solid, non hydraulic lifters) to make sure the valves were fully closed. I could also just remove the rocker arms completely.

Then I used the piston stop on the cylinder opposite the firing order to prevent the crank from turning under the air pressure. Opposite pistons: 1:6, 2:3, 4:7, 5:8

Then Applied 100PSI to get the first reading. Number 8 cylinder is losing 20%.

Then I put the spark plugs into the neighboring cylinders to help rule out a head gasket breach between cylinders.

Next I use a piece of hose to my ear and listen to locate where the 20% of air is going to.

Carb: Intake Valve

Exhaust:Exhaust Valve

Dip Stick (Crankcase): Past the piston rings (Normal)

Radiator: Cracked head or cylinder wall.

I wrote down all the results:

Might be time for a rebuild, what do you think?