This will be a sticky and be locked when done. Please begin another thread for comments. Thanks.

I am building this 850 Thermoquad for Jeremy (JMacMopars) for his 318. This is a step by step how to on teardown and reassembly.

First, begin by turning the carburetor upside down and soaking the body screws through the back side on the under side of the base plate with P'Blaster. The screws are steel and the base plate is aluminum. They have a nasty habit of corroding.

I want to thank my beautiful wife Kitty for the great pictures. I couldn't have done it without her.

Next, begin removing all of the exterior accessories. Here, I am removing the choke pulloff/vacuum brake.

The retaining screw is up in the corner.

Next, remove the anti dieseling solenoid, if so equipped.

Next, remove the pump lever screw.

The air screws have a really nasty habit of corroding to the base plate soak the hell out of them with P'Blaster. I find trying to tighten them a little first helps break them loose. I was lucky. I got both of these out.

Next, remove the pump discharge nozzle retaining screw.

Then reach in and lift out the discharge nozzle.

There are two screws RIGHT in front of the rear of the choke horn on either side of center. Remove them.

Reach in with a good pair of needle nosed pliers and gently pull them out.

Next, remove the remaining body screws. You may need to tap firmly on the screwdriver with a small hammer to help break the screws loose. You'll thank yourself for the P'Blaster you used earlier.

Next, remove the main metering rod piston retaining screw and retainer.

We're getting to some small screws here. As a general rule, I like to replace the screws back where they go. Helps to keep up with them.

Remove the air cleaner stud next. This thing was a hermorpadite. 1/4" on the bottom and 5/16" on top.

Remove the choke linkage lever screw.

Replace the screw so you'll know where it is.

With the choke linkage now out of the way, you can now gently remove the metering piston and rod assembly.

Remove the primary piston spring.

Remove the metering rod covers. Make sure to replace the screws to keep up with them.

Remove the fuel fitting in the top of the case and filter if there is one.

CAREFULLY get something between the plastic body and top case and gently pry it apart.

This is one nasty carburetor. I am not certain it will live to be rebuilt. But don't worry, Jeremy, I have an 850 just like it in better shape if it does not.

Remove the secondary air baffle from the center section.

This is an important picture. ...and a common one for Thermoquads. Notice that BOTH main jet wells have broken off and are still in the base plate. that's ok though, because they fit like a glove where they belong. A little fuel proof epoxy and they will be good as new.

Note the direction of installation of the cam lever and remove it.

Remove the float retaining pins.

Sometimes you need to get a knife edge under the pin head to persuade it to move.

These beauties will be replaced with brass floats.

The first picture shows me prying the fuel transfer tube off with my knife. The second shows the transfer tube removed.

Remove the right and left jet covers. They unscrew with a wrench.

Remove the cap on the bottom of the pump housing. You have to destroy it to remove it. It's ok because you get a new one in the kit.

Never seen rubber rust to aluminum.........until now. I had to soak hell out of the acellerator pump just to get it out. But as you can see, I won.

It is imperative to remove all of the gasket material possible. Sometimes you just cannot get it all.

Next, remove the needle and seat assemblies. There is one of each on each side where the floats came off.

And that's that until probably Tuesday evening when I'll remove and rinse it off. Remember do not put the choke pulloff or solenoid in the cleaner. Nothing but metal should go into the cleaner. Stay tuned and I'll be going back together.

~Rob

First off, I want to apologize to Jeremy for me taking so long with this. You've been extremely patient and it's much appreciated.

As promised, here's the rest of the writeup. Sorry about the crappy pics. Mrs Kitty's at work so I plugged on and did it myself.

Here is the repaired main body. Both main jet wells were broken completely off upon disassembly. I use a product called "Seal All". It is available from Advance Auto Parts. It is gas and oil proof. Works real good.

The key to making this as easy as possible is to lay your parts out so that you can see everything. I like to use Borg Warner kits as they are pretty complete. See also the upgrade to brass floats. One thing I immediately do after rinsing and blowing the parts dry is spray all of the ferrous metal down with PBlaster to keep rusting to a minimum. That's why I have a rag under the parts, to soak it up and keep it damp.

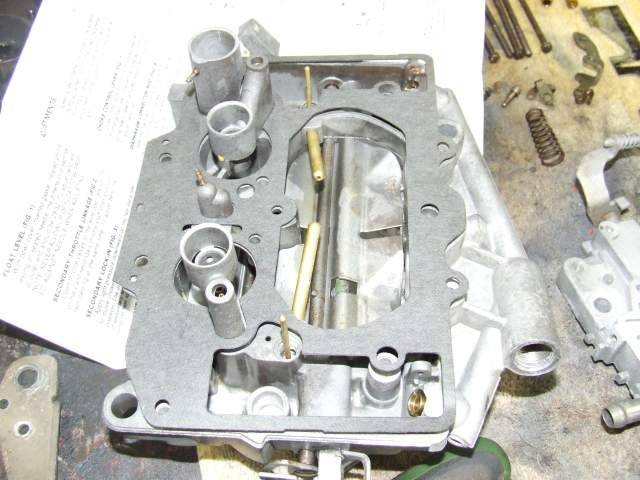

The first thing I always do on these is assemble the top plate first. Find your needles and seats and the seat gaskets in the kit. It is imperative that you look into the wells where the seats screw into the top plate to make SURE the old gaskets are not still there. These were, so I blew them out with air. Put the new seat gaskets on and screw the seats into the top plate. At this time, you will also want to install the top plate gasket. It may seem premature, but the gasket must be installed now, because installation of future parts will prevent installing it later.

Spray the accelerator pump with lubricant to avoid tearing the rubber seal when you install it. install the spring with the small end TOWARD the pump piston. Then install the assembly into the accelerator pump well. Find the new accelerator pump check valve/cover in the kit and gently tap it in place with a small hammer. Next, reinstall the small "S" linkage through the hole in the accelerator pump rod on the outside of the top plate. Then, find the pump transfer tube in the kit. Spray each nipple with lubricant and install the transfer tube. Be careful because it is fragile. It is the small black hose in the picture. Install it so that a good portion of each end goes over each barb, or it WILL come off.

Install the seats and the floats as shown. Make sure you install the float pins from the inside, not the outside, as the pin heads will interfere with the top plate bolting down. Adjust the float so that the flat portion that's actually the bottom at the very front is 29/32" from the gasket surface. Yes, those are the deestruckshuns in the background. If you find a carburetor man says he doesn't need them, you better run.

Next, install both jet covers and you're pretty much done with the inside of the top plate.

Now install the primary piston step in the base plate. Next, install the accelerator pump check valve in the top plate, then the gasket and the pump squirter and retaining screw.

Install the main body to base plate gasket on the base plate and then the plastic main body on the base plate. Now, CAREFULLY lower the top plate down on the main body. You just made a Thermoquad sammich.

Now, here is one thing I do on these particular carburetors that a lot of people do not. I coat every long bolt with prematex. This does two things. It seals the bolts from leaking vacuum and it keeps them from corroding steel on aluminum. In other words, you can get them out next time. Install each main screw and tighten from the inside out.

Now find the primary piston and lube it up. I like to use permatex anti sieze. Don't glop it on because you actually want the piston to WORK. Next, install the primary piston spring. Then lube the two titties up on the metering rod bar. The titties on the bar scrub the back of the choke horn and it doesnt hurt to put some lubricant there. Now lower the metering rods STRAIGHT down onto the rod holes and make sure they fall ALL the way down...and STRAIGHT. That means they are in the main jets. Take the metering rod bar and gently depress it down just enough to install the primary piston retainer and screw. Now, with needle nose pliers, gently lift the metering rods up just enough to install them into the holes in each end of the metering rod bar. You may need to tweak the bar ends to get the rods installed. Do NOT bend the rods themselves. After you're done with that, gently depress the metering rod bar and primary piston assembly down until it seats softly and hold it there. Take a small screwdriver and adjust the metering rid screw in the middle until the entire metering rod bar JUST stops going down. Now, turn the screw and adjust the bar until it JUST stops coming up and that is your base line adjustment. There are many other adjustments, but since I don't have a test mule, I cannot go over those.

Reconnect the choke linkage and reinstall the choke pull off/vacuum break and the carburetor is done.

Jeremy, I will get this out to you as soon as I can. Please don't be frustrated if it is hard to tune. Call me. You have my number. I will walk you through it and if it is something I need to redo, I stand behind my work 100%. Bear with me since I don't have a test mule. I am hoping to have one soon and then I can really do something.

Here it is in all its glory. I think it turned out pretty good considering it was a nasty beeotch. lol

I am building this 850 Thermoquad for Jeremy (JMacMopars) for his 318. This is a step by step how to on teardown and reassembly.

First, begin by turning the carburetor upside down and soaking the body screws through the back side on the under side of the base plate with P'Blaster. The screws are steel and the base plate is aluminum. They have a nasty habit of corroding.

I want to thank my beautiful wife Kitty for the great pictures. I couldn't have done it without her.

Next, begin removing all of the exterior accessories. Here, I am removing the choke pulloff/vacuum brake.

The retaining screw is up in the corner.

Next, remove the anti dieseling solenoid, if so equipped.

Next, remove the pump lever screw.

The air screws have a really nasty habit of corroding to the base plate soak the hell out of them with P'Blaster. I find trying to tighten them a little first helps break them loose. I was lucky. I got both of these out.

Next, remove the pump discharge nozzle retaining screw.

Then reach in and lift out the discharge nozzle.

There are two screws RIGHT in front of the rear of the choke horn on either side of center. Remove them.

Reach in with a good pair of needle nosed pliers and gently pull them out.

Next, remove the remaining body screws. You may need to tap firmly on the screwdriver with a small hammer to help break the screws loose. You'll thank yourself for the P'Blaster you used earlier.

Next, remove the main metering rod piston retaining screw and retainer.

We're getting to some small screws here. As a general rule, I like to replace the screws back where they go. Helps to keep up with them.

Remove the air cleaner stud next. This thing was a hermorpadite. 1/4" on the bottom and 5/16" on top.

Remove the choke linkage lever screw.

Replace the screw so you'll know where it is.

With the choke linkage now out of the way, you can now gently remove the metering piston and rod assembly.

Remove the primary piston spring.

Remove the metering rod covers. Make sure to replace the screws to keep up with them.

Remove the fuel fitting in the top of the case and filter if there is one.

CAREFULLY get something between the plastic body and top case and gently pry it apart.

This is one nasty carburetor. I am not certain it will live to be rebuilt. But don't worry, Jeremy, I have an 850 just like it in better shape if it does not.

Remove the secondary air baffle from the center section.

This is an important picture. ...and a common one for Thermoquads. Notice that BOTH main jet wells have broken off and are still in the base plate. that's ok though, because they fit like a glove where they belong. A little fuel proof epoxy and they will be good as new.

Note the direction of installation of the cam lever and remove it.

Remove the float retaining pins.

Sometimes you need to get a knife edge under the pin head to persuade it to move.

These beauties will be replaced with brass floats.

The first picture shows me prying the fuel transfer tube off with my knife. The second shows the transfer tube removed.

Remove the right and left jet covers. They unscrew with a wrench.

Remove the cap on the bottom of the pump housing. You have to destroy it to remove it. It's ok because you get a new one in the kit.

Never seen rubber rust to aluminum.........until now. I had to soak hell out of the acellerator pump just to get it out. But as you can see, I won.

It is imperative to remove all of the gasket material possible. Sometimes you just cannot get it all.

Next, remove the needle and seat assemblies. There is one of each on each side where the floats came off.

And that's that until probably Tuesday evening when I'll remove and rinse it off. Remember do not put the choke pulloff or solenoid in the cleaner. Nothing but metal should go into the cleaner. Stay tuned and I'll be going back together.

~Rob

First off, I want to apologize to Jeremy for me taking so long with this. You've been extremely patient and it's much appreciated.

As promised, here's the rest of the writeup. Sorry about the crappy pics. Mrs Kitty's at work so I plugged on and did it myself.

Here is the repaired main body. Both main jet wells were broken completely off upon disassembly. I use a product called "Seal All". It is available from Advance Auto Parts. It is gas and oil proof. Works real good.

The key to making this as easy as possible is to lay your parts out so that you can see everything. I like to use Borg Warner kits as they are pretty complete. See also the upgrade to brass floats. One thing I immediately do after rinsing and blowing the parts dry is spray all of the ferrous metal down with PBlaster to keep rusting to a minimum. That's why I have a rag under the parts, to soak it up and keep it damp.

The first thing I always do on these is assemble the top plate first. Find your needles and seats and the seat gaskets in the kit. It is imperative that you look into the wells where the seats screw into the top plate to make SURE the old gaskets are not still there. These were, so I blew them out with air. Put the new seat gaskets on and screw the seats into the top plate. At this time, you will also want to install the top plate gasket. It may seem premature, but the gasket must be installed now, because installation of future parts will prevent installing it later.

Spray the accelerator pump with lubricant to avoid tearing the rubber seal when you install it. install the spring with the small end TOWARD the pump piston. Then install the assembly into the accelerator pump well. Find the new accelerator pump check valve/cover in the kit and gently tap it in place with a small hammer. Next, reinstall the small "S" linkage through the hole in the accelerator pump rod on the outside of the top plate. Then, find the pump transfer tube in the kit. Spray each nipple with lubricant and install the transfer tube. Be careful because it is fragile. It is the small black hose in the picture. Install it so that a good portion of each end goes over each barb, or it WILL come off.

Install the seats and the floats as shown. Make sure you install the float pins from the inside, not the outside, as the pin heads will interfere with the top plate bolting down. Adjust the float so that the flat portion that's actually the bottom at the very front is 29/32" from the gasket surface. Yes, those are the deestruckshuns in the background. If you find a carburetor man says he doesn't need them, you better run.

Next, install both jet covers and you're pretty much done with the inside of the top plate.

Now install the primary piston step in the base plate. Next, install the accelerator pump check valve in the top plate, then the gasket and the pump squirter and retaining screw.

Install the main body to base plate gasket on the base plate and then the plastic main body on the base plate. Now, CAREFULLY lower the top plate down on the main body. You just made a Thermoquad sammich.

Now, here is one thing I do on these particular carburetors that a lot of people do not. I coat every long bolt with prematex. This does two things. It seals the bolts from leaking vacuum and it keeps them from corroding steel on aluminum. In other words, you can get them out next time. Install each main screw and tighten from the inside out.

Now find the primary piston and lube it up. I like to use permatex anti sieze. Don't glop it on because you actually want the piston to WORK. Next, install the primary piston spring. Then lube the two titties up on the metering rod bar. The titties on the bar scrub the back of the choke horn and it doesnt hurt to put some lubricant there. Now lower the metering rods STRAIGHT down onto the rod holes and make sure they fall ALL the way down...and STRAIGHT. That means they are in the main jets. Take the metering rod bar and gently depress it down just enough to install the primary piston retainer and screw. Now, with needle nose pliers, gently lift the metering rods up just enough to install them into the holes in each end of the metering rod bar. You may need to tweak the bar ends to get the rods installed. Do NOT bend the rods themselves. After you're done with that, gently depress the metering rod bar and primary piston assembly down until it seats softly and hold it there. Take a small screwdriver and adjust the metering rid screw in the middle until the entire metering rod bar JUST stops going down. Now, turn the screw and adjust the bar until it JUST stops coming up and that is your base line adjustment. There are many other adjustments, but since I don't have a test mule, I cannot go over those.

Reconnect the choke linkage and reinstall the choke pull off/vacuum break and the carburetor is done.

Jeremy, I will get this out to you as soon as I can. Please don't be frustrated if it is hard to tune. Call me. You have my number. I will walk you through it and if it is something I need to redo, I stand behind my work 100%. Bear with me since I don't have a test mule. I am hoping to have one soon and then I can really do something.

Here it is in all its glory. I think it turned out pretty good considering it was a nasty beeotch. lol