1967formulaS

Well-Known Member

Get some 4.3 gears for the rear and you will be fine.

....i can't believe any body would select a 383 over a 440

Cubic inch builds torque not Horsepower, 383 is in a slight disadvantage in the hp department because of the slightly smaller bore which cost some potential airflow

(Horsepower).

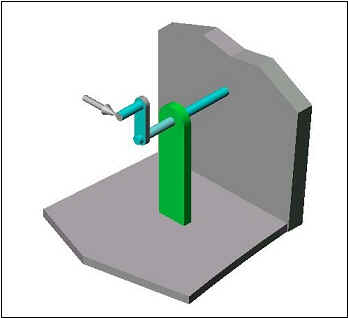

Figure 1

Figure 1

....i can't believe any body would select a 383 over a 440

m383???

i wouldn't select either myself,i'm small block all the way.But it has always been my understanding that a 440 will out perform a 383 in every way...maybe i'm wrong.

m

maybe, but a 383 will out perform a smallblock any day all day.

but that isn't what this thread is about.

Damn skippy^^^^^^^

Horsepower is calculated from a measured torque reading...they are essentially the same. If you don't understand this relationship, do yourself a favor and read

... the original question was which engine would be best for the old girl?

do we have a winner?

Long live the 383. Coincidentally, I just picked one up tonight for scrap money. He was gonna scrap it! Heavens to Mergatroid!