68val_100

Member

Heyguys and gals. I have a 68 valiant with a 170 and a column 3spd. Original motor. I am enrolled at my local college and in my engine machining class my shop teacher gave me a short block 170 someone left there over 5 yrs now. I opened it up and everything is new or no miles since rebuilt. Crank, cam, 40 over pistons, bearings, and timing chain. I am going to tear it all back down and clean out the grime from sitting all these years and reassemble.

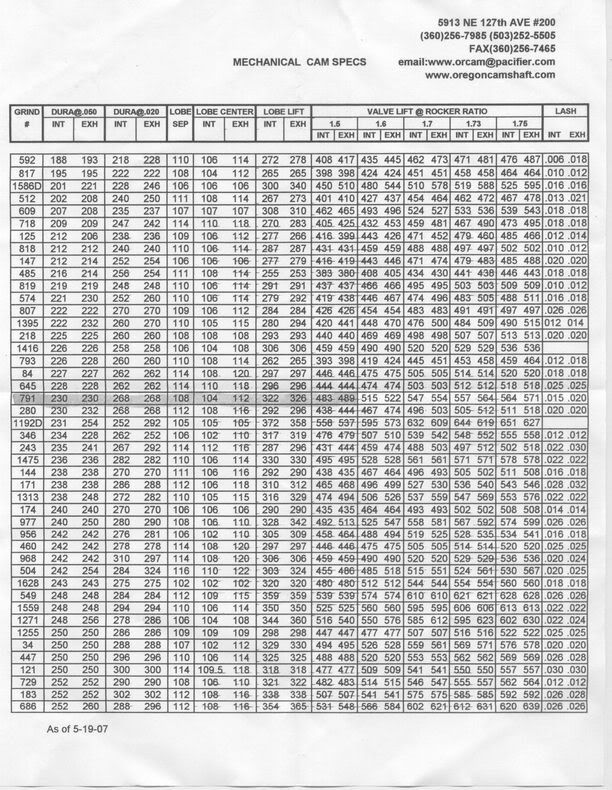

Now I am asking what else should I do for performance wise? I plan on a 4 barrel setup and dutra manifolds. Mill the head and block? Get the cam reground and what specs for a more agressive sound and performance? And this car is my daily driver.

And this is what its going in.

Now I am asking what else should I do for performance wise? I plan on a 4 barrel setup and dutra manifolds. Mill the head and block? Get the cam reground and what specs for a more agressive sound and performance? And this car is my daily driver.

And this is what its going in.