lelo, that was my next question, if i port the heads i have based on the head porting sticky on here and have them milled slightly that should be a big help theyre supposed to be 60-62 cc's am i correct in this thinking. and does anyone other than kb make a higher compression piston for the 318?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

302 heads

- Thread starter ktcnn94

- Start date

-

Whoa! I didn't know the KBs cost that much! I don't think I paid near that much, think it was 250-300ish a few years ago. I totally understand. I think you are correct with the 62cc and yes I think you could get good results with your stock heads. But I won't pretend to be some kind of porting pro or anything there are a lot of people around here more knowledgeable than me about that sort of thing.

yeah theyre crazy high. ive read that porting sticky on here a couple of times. I think I can do it. im not afraid to try .but what ever is best bang for the buck, if I do end up running across a 360 on the cheap some how (ive found em around here for $400-$600 and theyre smog motors seems high to me for a core but I may be wrong anyone that knows feel free to chime in, im always open to suggestions and thoughts) anyway, are there any necessary changes or parts I need to change from 318 to 360 like different mounts, flexplate, convertor etc.

Treblig

Well-Known Member

NO, the 308 heads are OPEN chamber

According to the "How To Hot Rod Small Block Mopar Engine's" Book the 308s were swirl port just like the 302s:

Treblig

Attachments

It sounds to me like the 302's will be fine for what you're planning on doing. Just get a clean set and try to avoid dumping a bunch of money into rebuilding them. I wouldn't cut them much either, as that will end up costing you a bunch with custom length pushrods and milling the intake.

The 302's came on 318's from '85-'89, if you can find a set in the junkyard you'll pay a lot less for them. I would just have them magnafluxed to be sure they're free of cracks, get a valve job and a quick surface cut just to true them up. Run them with a set of Mr Gasket 1121G head gaskets, they're .028" compressed, to bump the compression a little more.

If that's all you do to them, and you're not looking for anything much over 300 hp, the 302's will be great. Just don't be tempted to sink a bunch of money into them trying to make them performance heads, otherwise you'll spend more money than a new set of heads will cost.

The 302's came on 318's from '85-'89, if you can find a set in the junkyard you'll pay a lot less for them. I would just have them magnafluxed to be sure they're free of cracks, get a valve job and a quick surface cut just to true them up. Run them with a set of Mr Gasket 1121G head gaskets, they're .028" compressed, to bump the compression a little more.

If that's all you do to them, and you're not looking for anything much over 300 hp, the 302's will be great. Just don't be tempted to sink a bunch of money into them trying to make them performance heads, otherwise you'll spend more money than a new set of heads will cost.

According to the "How To Hot Rod Small Block Mopar Engine's" Book the 308s were swirl port just like the 302s:

Treblig

Yes, they are swirl PORT heads. Ports are not chambers. The 308's are also open chamber, and have the larger 360 sized ports. The section right after the bit you highlighted says the chambers are similar to the earlier 340/360 heads, which are open chambers.

This is a picture of the 308's on my 340. They're obviously open chambers. In fact, the only reason I used the 308's and had them ported was because they are open chambers and would clear the pistons in my 340, which are .018" proud of the deck. You can just about make out the "308" casting number as well, it's upside down on the top right.

Treblig

Well-Known Member

Yes, they are swirl PORT heads. Ports are not chambers. The 308's are also open chamber, and have the larger 360 sized ports. The section right after the bit you highlighted says the chambers are similar to the earlier 340/360 heads, which are open chambers.

This is a picture of the 308's on my 340. They're obviously open chambers. In fact, the only reason I used the 308's and had them ported was because they are open chambers and would clear the pistons in my 340, which are .018" proud of the deck. You can just about make out the "308" casting number as well, it's upside down on the top right.

I hear that when you properly cook "crow" it tastes pretty good. Pass the salt please!! YUM< YUM!!!

Treblig

I hear that when you properly cook "crow" it tastes pretty good. Pass the salt please!! YUM< YUM!!!

Treblig

Hey it happens. Just don't microwave it too long. :violent2:

There's more than a couple of my old posts on here that I wish I could delete. ;)

yeah theyre crazy high. ive read that porting sticky on here a couple of times. I think I can do it. im not afraid to try .but what ever is best bang for the buck, if I do end up running across a 360 on the cheap some how (ive found em around here for $400-$600 and theyre smog motors seems high to me for a core but I may be wrong anyone that knows feel free to chime in, im always open to suggestions and thoughts) anyway, are there any necessary changes or parts I need to change from 318 to 360 like different mounts, flexplate, convertor etc.

Were you planning on rebuilding you 318? Does it run good now? Do you have headers, dual exhaust, & 4 barrel? Those are good places to start and will increase performance. I think speed-pro has some better than stock compression pistons.

it has an edelbrock performer intake and an edelbrock 4bbl, it has duals on it no headers, my original plan was to put headers on it and stick an ex268 cam in it for the summer and then do an engine overhaul or replacement next winter and since it wouldn't get a bunch of miles on it I coud just reuse the cam on the fresh build. (ive spent this winter working on the interior). when I posted a thread inquiring opinions on that cam it opened up this whole thing on the compression and cylinder head issues so I was gonna try to find me a set of heads and go from there. it does run ok at this point, no noises (a little smoke on start up) but doesn't seem to be using any oil. ive been told so many things and I know everyone means well and has their own opinions but now im not sure what to do I may just put headers on it and ride it this summer and collect parts throughout the summer as I get the money, while doing more research. I like the 318 but everyone keeps saying 360.

According to the "How To Hot Rod Small Block Mopar Engine's" Book the 308s were swirl port just like the 302s:

Treblig

Swirl port has nothing to do with the chamber type. 302s are close chamber. 308s are open chamber.

Also, if you read the MP engine manual....and I have said this ALOT, Larry Shepard clearly talks about when they "accidentally" found "swirl port" heads and it was LONG before the 308s were even thought about. He never cites a casting number, but from the context he was clearly talking about the early 70s. So that pretty much means all the heads through the 70s were actually swirl port heads. It's in the book. Read it.

lelo, that was my next question, if i port the heads i have based on the head porting sticky on here and have them milled slightly that should be a big help theyre supposed to be 60-62 cc's am i correct in this thinking. and does anyone other than kb make a higher compression piston for the 318?

I had my virgin 714's (302' twin sister 1990 d150) milled .010 then I polished the chambers using just sand paper. The chambers ranged from 59.8 to 61.6.

Attachments

I wouldn't get to stressed out about compression of course it's gonna run better with more cr but it's all about compromises, 318 are low to mid 8's:1 but as long you don't want to go to crazy with cam, your cam choice is probably on the edge of what will work acceptably with a stock long block. But if 302's fit with your future plans for your car then go for it but if not I'd spend the money on gears or something else.

I think the headers will give you a increase in power you could actually feel and will work with other small blocks if you decide to swap motors. Dougs on sale is the ticket. Chambered mufflers can give you that sound you are looking for. I usually look for flow = more power. If you love your teener then keep it, it can be a strong running motor.

Louie70Dart

Southern IL. Complete opposite of k-town

302's are for cars, but isn't there the same style heads that were used for truck engines?

walk1169

New Member

Just build it the way u want to.302,308,blah,blah,blah.cam it them run it....

302's are for cars, but isn't there the same style heads that were used for truck engines?

302's came in trucks too. The 302's I have are on a 318 out of a truck. In fact, I had to come up with another transmission because it was a 4x4.

Just build it the way u want to.302,308,blah,blah,blah.cam it them run it....

An excellent way to end up with an overcammed, low compression engine that doesn't perform as intended.

Two7T3Dart

....

. I bet some of yall have never run the damn things before. I have. On both a 318 and 360. They ran fine.

Hey Rusty....how did they work on a 360? I was considering this as a cheap way to up compression on a stock '79 360.....

ktcnn94; From what it sounds like what you want, you will be very happy with a set of 302s. I have run them on a stock 318 with a cam(headers, x-pipe, 4 barrel...) and it ran really good.

I do however agree don't put bigger valves in them. No need. They will be good for decent power without and that costs too much. Do a valve job, maybe a mill to clean the up, the self pocket port and run them with a decent cam, and thin head gaskets(Like said). Then in the future get a better set of heads like the LAX, if you want to make 400hp.

I do however agree don't put bigger valves in them. No need. They will be good for decent power without and that costs too much. Do a valve job, maybe a mill to clean the up, the self pocket port and run them with a decent cam, and thin head gaskets(Like said). Then in the future get a better set of heads like the LAX, if you want to make 400hp.

CPDave

Spin Cycle

Thought I'd add a little data to this discussion. First we all know that bigger, better flowing heads make more power, but there is a lot of other stuff that has to go into the combination to exploit heads that flow 270-320 CFM @ 0.600" & 28" of water.

So, say your running a dual plain intake, and 8.8-10.5:1 compression, want to run pump gas, have a nice wide torque curve, don't want to spin the motor past 7000, and aren't running a stroker... Now a smaller head may begin to make more sense. So how much power can you get out of a ...302 casting? That depends on the flow available at the intake valve, so here are some numbers (all @ 28" of water):

STOCK 302 1.78"/1.5" (Shady Dell)

0.100" 62.8 NA

0.200" 125.6 70.9

0.300" 158.4 92.8

0.400" 169.3 99.6

0.450" 170.6 101.0

0.500" 170.6 102.4

0.550" 170.6 102.4

0.600" 170.6 102.4

As Cast "302" 1.78"/1.50" (MD Performance Center)

0.100 51.8 36.5

0.200 92.5 70.7

0.300 130.1 104.3

0.400 163.9 113.2

0.450 169.1 115.2

0.500 170.4 117.3

0.550 172.2 119.0

0.600 172.5 120.4

Ported

"302" 2.02"/1.60" (Shady Dell)

0.100 71.8 42.5

0.200 148.4 86.3

0.300 212.2 113.9

0.400 241.5 131.1

0.450 244.6 137.7

0.500 246.7 139.7

0.550 242.6 144.9

0.600 240.8 144.9

Ported "...302" Heads 1.94"/1.60" (Shady Dell)

on a 4.040" Bore (heads currently on my Dart's

0.050 over 318 (326Cid):

LIFT IN / Out

0.100" 66.1 / 48.4

0.200" 132.8 / 90.4

0.300" 189.9 / 126.2

0.400" 218.4 / 148.8

0.450" 227.9 / 152.9

0.500" 232.8 / 159.8

0.550" 238.0 / 163.9

0.600" 239.1 / 169.8

Same 1.94/1.6 302 head on MPC's bench on a 4.030" Bore

LIFT IN / EX

0.100" 65.7 / 49.6

0.200" 128.6 / 94.5

0.300" 174.7 / 130.6

0.400" 208.6 / 157.5

0.450" 216.6 / 166.0

0.500" 205.7 / 171.1

0.550" 210.0 / 173.3

0.600" 213.1 / 173.2

Some other Small chamber heads:

273 Cleanup Port/Valve Job 1.78"/1.50"

(pretty much a "stock" class vavle job)

0.100" 49 43

0.200" 98 85

0.250" 124 100

0.300" 145 112

0.350" 162 120

0.400" 179 125

0.450" 188 129

0.500" 190 132

0.550" 185 134

0.600" 177 135

273 Ported 1.88"/1.60" (note the biggest intake

gains are at lower lift, suspect the intake valve get's

shrouded against the side of the combustion

chamber at higher lifts):

0.100" 60.93 48.78

0.200" 122.75 99.78

0.300" 179.68 137.16

0.400" 197.02 157.11

0.500" 185.91 168.20

0.600" 187.24 179.29

So how much power can a stock 302 head support? Well they flow roughly 170 CFM @ 0.500 & 28" of water, the thumb rule for this is:

Horsepower per cylinder = .43 x airflow @ 10" of water,

.275 x airflow @ 25" of water, or

.26 x airflow @ 28" of water.

So 0.26 x 170 x 8 = 353 HP at the crank (if everything is optimized you

might be able to 10% better, say 385 HP).

What is the impact of porting on this? Taking the average of MPC and Shady Dell's numbers we get 226 CFM @ 0.600" and 28" of water:

0.26 x 226 x 8 = 470 HP at the crank (again, if everything is optimized you

might be able to do 10% better, say 523 HP).

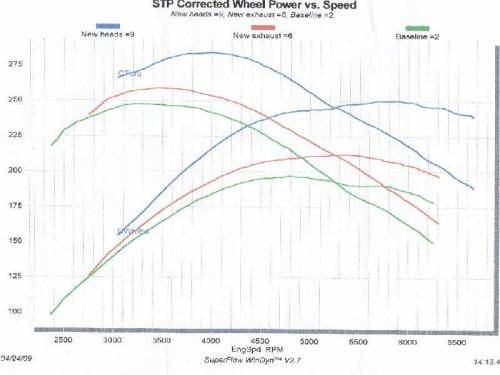

So that's theory, how'd it really work out? Below are a series of chassis dyno plots (all for the same short block and intake manifold (LD4B)). The first set of three shows a baseline (Green) with 9.1:1 compression, unported 302 heads, 0.420" lift mech cam, and stock early A-body exhaust manifolds dumping into a single 3" exhaust, 750 Holley. The Red trace shows the impact of TTI headers, 3"-in-2.5"-out X-pipe, glass packs dumping in front of the rear wheels, and Hughes roller rockers. Next (Blue) is the swap to the ported 302 castings, with a 0.005" clean up cut these cc'd slightly smaller than the unmolested 302s and bumped the compression to 9.25:1. A tidy gain of 54 Hp and 46 FtLb without so much as pulling off the water pump. So Time for a Cam...

The Existing cam was a flat tappet Mechanical:

Intake Exhaust

Valve Lift 0.420" 0.420"

Advertised Dur: 262° 262°

Dur @ 0.05" Lift: 219° 219°

Lobe Sep: 110°

Intake Center Line: 106°

The new cam is a Comp Cams Mech Roller:

Lift: 0.630" 0.630"

Dur@0.050": 254° 260°

AdvDur(@0.006"): 284° 292°

LSA: 107°

Int Center Line: 102°

Lash: 0.022"-0.024".

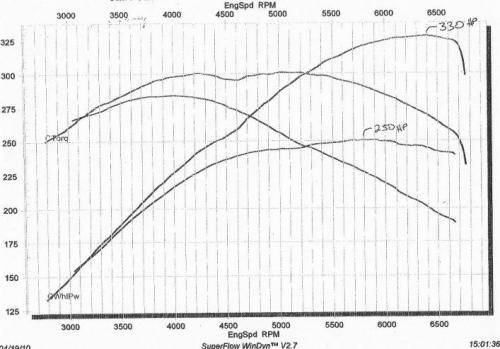

Additionally the heads were milled 0.030, which netted roughly a 10.1:1 CR, and we replaced the vacuum secondary 750 Holley with a QFT 750 Double pumper... The second image below (black & white plot) compares the blue plot from the previous graph to the results of the cam, compression, and carb change; net 85 HP & 15 FtLb

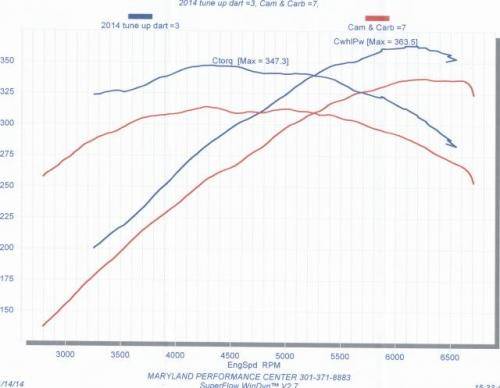

Sooo, then I hurt the motor and we rebuilt it with lighter forged pistons (previously was 0.045"over KBs about 0.020" down the bore), a 0.050" over bore (only needed a 0.005" hone to clean up), a compression ratio of 10.25:1, and Harland Sharp rockers replacing the Hughes rockers which were getting tired too quickly in this application (road race/street). I added a 0.5 partially open carb spacer and we also replaced glass packs with some 16" long oval Borla mufflers (quieter!). This netted another 33 Hp and 47 FtLb (the blue traces on the final graph). Still digests pump 93 gas.

Is there more there with better heads and intake, you bet, but this is plenty to pull to 150MPH on the front straight at Summit Point. My rule book is a little restrictive, I have to use a 273/318/destroked 340 (less than 5000cc), Iron heads, and one of the following manifolds: LD4B, LD340, Performer, or Performer RPM.

So the final question might be, what would the stock 302 heads be like on a 360? Another Thumb rule says:

RPM at peak horsepower = (N / one cylinder displacement (ci)) x CFM

N = 2,000 @ 10" of water

N = 1,267 @ 25" of water

N = 1,196 @ 28" of water

So a 0.030" over 360 cylinder = 45.66 ci

(1,196 / 45.66) 170 = 4452 RPM

and Ported:

(1,196 / 45.66) 226 = 5919

and a .045 over 318 = 40.66 ci

(1,196 / 40.66) 170 = 5000 RPM (in the real world with headers it peaked about 5300)

and Ported:

(1,196 / 40.66) 226 = 6647 (ITRW It peaked about 6300)

So yes, you could make more power with better heads, but looking at the torque curves and considering the throttle response that a high flowing but smaller port can provide, the high turbulence/quench combustion chambers also provide greater efficiency and tolerance for lower octane fuel, so there is a place for the 302 head in a street performance or moderate competition build.

Dave

View attachment DrtEng20141119sml.jpg

View attachment DRTDYN3.jpg

View attachment DRTDYN4.jpg

So, say your running a dual plain intake, and 8.8-10.5:1 compression, want to run pump gas, have a nice wide torque curve, don't want to spin the motor past 7000, and aren't running a stroker... Now a smaller head may begin to make more sense. So how much power can you get out of a ...302 casting? That depends on the flow available at the intake valve, so here are some numbers (all @ 28" of water):

STOCK 302 1.78"/1.5" (Shady Dell)

0.100" 62.8 NA

0.200" 125.6 70.9

0.300" 158.4 92.8

0.400" 169.3 99.6

0.450" 170.6 101.0

0.500" 170.6 102.4

0.550" 170.6 102.4

0.600" 170.6 102.4

As Cast "302" 1.78"/1.50" (MD Performance Center)

0.100 51.8 36.5

0.200 92.5 70.7

0.300 130.1 104.3

0.400 163.9 113.2

0.450 169.1 115.2

0.500 170.4 117.3

0.550 172.2 119.0

0.600 172.5 120.4

Ported

"302" 2.02"/1.60" (Shady Dell)

0.100 71.8 42.5

0.200 148.4 86.3

0.300 212.2 113.9

0.400 241.5 131.1

0.450 244.6 137.7

0.500 246.7 139.7

0.550 242.6 144.9

0.600 240.8 144.9

Ported "...302" Heads 1.94"/1.60" (Shady Dell)

on a 4.040" Bore (heads currently on my Dart's

0.050 over 318 (326Cid):

LIFT IN / Out

0.100" 66.1 / 48.4

0.200" 132.8 / 90.4

0.300" 189.9 / 126.2

0.400" 218.4 / 148.8

0.450" 227.9 / 152.9

0.500" 232.8 / 159.8

0.550" 238.0 / 163.9

0.600" 239.1 / 169.8

Same 1.94/1.6 302 head on MPC's bench on a 4.030" Bore

LIFT IN / EX

0.100" 65.7 / 49.6

0.200" 128.6 / 94.5

0.300" 174.7 / 130.6

0.400" 208.6 / 157.5

0.450" 216.6 / 166.0

0.500" 205.7 / 171.1

0.550" 210.0 / 173.3

0.600" 213.1 / 173.2

Some other Small chamber heads:

273 Cleanup Port/Valve Job 1.78"/1.50"

(pretty much a "stock" class vavle job)

0.100" 49 43

0.200" 98 85

0.250" 124 100

0.300" 145 112

0.350" 162 120

0.400" 179 125

0.450" 188 129

0.500" 190 132

0.550" 185 134

0.600" 177 135

273 Ported 1.88"/1.60" (note the biggest intake

gains are at lower lift, suspect the intake valve get's

shrouded against the side of the combustion

chamber at higher lifts):

0.100" 60.93 48.78

0.200" 122.75 99.78

0.300" 179.68 137.16

0.400" 197.02 157.11

0.500" 185.91 168.20

0.600" 187.24 179.29

So how much power can a stock 302 head support? Well they flow roughly 170 CFM @ 0.500 & 28" of water, the thumb rule for this is:

Horsepower per cylinder = .43 x airflow @ 10" of water,

.275 x airflow @ 25" of water, or

.26 x airflow @ 28" of water.

So 0.26 x 170 x 8 = 353 HP at the crank (if everything is optimized you

might be able to 10% better, say 385 HP).

What is the impact of porting on this? Taking the average of MPC and Shady Dell's numbers we get 226 CFM @ 0.600" and 28" of water:

0.26 x 226 x 8 = 470 HP at the crank (again, if everything is optimized you

might be able to do 10% better, say 523 HP).

So that's theory, how'd it really work out? Below are a series of chassis dyno plots (all for the same short block and intake manifold (LD4B)). The first set of three shows a baseline (Green) with 9.1:1 compression, unported 302 heads, 0.420" lift mech cam, and stock early A-body exhaust manifolds dumping into a single 3" exhaust, 750 Holley. The Red trace shows the impact of TTI headers, 3"-in-2.5"-out X-pipe, glass packs dumping in front of the rear wheels, and Hughes roller rockers. Next (Blue) is the swap to the ported 302 castings, with a 0.005" clean up cut these cc'd slightly smaller than the unmolested 302s and bumped the compression to 9.25:1. A tidy gain of 54 Hp and 46 FtLb without so much as pulling off the water pump. So Time for a Cam...

The Existing cam was a flat tappet Mechanical:

Intake Exhaust

Valve Lift 0.420" 0.420"

Advertised Dur: 262° 262°

Dur @ 0.05" Lift: 219° 219°

Lobe Sep: 110°

Intake Center Line: 106°

The new cam is a Comp Cams Mech Roller:

Lift: 0.630" 0.630"

Dur@0.050": 254° 260°

AdvDur(@0.006"): 284° 292°

LSA: 107°

Int Center Line: 102°

Lash: 0.022"-0.024".

Additionally the heads were milled 0.030, which netted roughly a 10.1:1 CR, and we replaced the vacuum secondary 750 Holley with a QFT 750 Double pumper... The second image below (black & white plot) compares the blue plot from the previous graph to the results of the cam, compression, and carb change; net 85 HP & 15 FtLb

Sooo, then I hurt the motor and we rebuilt it with lighter forged pistons (previously was 0.045"over KBs about 0.020" down the bore), a 0.050" over bore (only needed a 0.005" hone to clean up), a compression ratio of 10.25:1, and Harland Sharp rockers replacing the Hughes rockers which were getting tired too quickly in this application (road race/street). I added a 0.5 partially open carb spacer and we also replaced glass packs with some 16" long oval Borla mufflers (quieter!). This netted another 33 Hp and 47 FtLb (the blue traces on the final graph). Still digests pump 93 gas.

Is there more there with better heads and intake, you bet, but this is plenty to pull to 150MPH on the front straight at Summit Point. My rule book is a little restrictive, I have to use a 273/318/destroked 340 (less than 5000cc), Iron heads, and one of the following manifolds: LD4B, LD340, Performer, or Performer RPM.

So the final question might be, what would the stock 302 heads be like on a 360? Another Thumb rule says:

RPM at peak horsepower = (N / one cylinder displacement (ci)) x CFM

N = 2,000 @ 10" of water

N = 1,267 @ 25" of water

N = 1,196 @ 28" of water

So a 0.030" over 360 cylinder = 45.66 ci

(1,196 / 45.66) 170 = 4452 RPM

and Ported:

(1,196 / 45.66) 226 = 5919

and a .045 over 318 = 40.66 ci

(1,196 / 40.66) 170 = 5000 RPM (in the real world with headers it peaked about 5300)

and Ported:

(1,196 / 40.66) 226 = 6647 (ITRW It peaked about 6300)

So yes, you could make more power with better heads, but looking at the torque curves and considering the throttle response that a high flowing but smaller port can provide, the high turbulence/quench combustion chambers also provide greater efficiency and tolerance for lower octane fuel, so there is a place for the 302 head in a street performance or moderate competition build.

Dave

View attachment DrtEng20141119sml.jpg

View attachment DRTDYN3.jpg

View attachment DRTDYN4.jpg

Hey Rusty....how did they work on a 360? I was considering this as a cheap way to up compression on a stock '79 360.....

Real good. It was a truck engine I built for my 73 D100. I had the Summit 6900 cam in it, performer intake, TQ and headers. I would imagine had it been much more, the heads might have been a factor, but it pulled very strong.

Very nice Dave. Thanks for the input.

-