You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

'76 Dart Lite -- Budget Boost Build

- Thread starter Backtobasics

- Start date

-

Backtobasics

Well-Known Member

Alright ladies and germs, tonight's update:

I took a piece of 5 inch scrap stainless, and some wire. Using what is left of my math memory, I took 5" x 3.14 (Pi), to get the circumference of the 5" pipe. I did the same with my target collector diameter of 2.5 x 3.14. I cut a wedge piece out of the 5" approximately 10 inches long, and used the wire, to squeeze the pipe down to the desired 2.5 side on the smaller end. I cut both ends straight, and trued on a band saw.

I took a piece of white paper and held it up to the turbo outlet housing and rubbed along the flange to make a paper gasket outline. I cut it out and transferred to the flat steel. I plasma cut the bulk of the center, cleaned it up a bit on the mill, and then welded the cone to the steel stock that has the opening of the flange on the hot side of the turbo, to make my own home - made down pipe stub.

Now, on to the pictures:

Sadly, this is all I was able to get done, but with the exception of drilling the holes and bolting it to the back of the turbo, this is most of the "to do" stuff I wanted to get done before I left the job.

I need to make gaskets, drill holes in the down pipe, and use my personal angle grinder to port the opening of the down pipe, and port the adapter for smooth flow out of the exhaust manifold and into the turbo housing.

I took a piece of 5 inch scrap stainless, and some wire. Using what is left of my math memory, I took 5" x 3.14 (Pi), to get the circumference of the 5" pipe. I did the same with my target collector diameter of 2.5 x 3.14. I cut a wedge piece out of the 5" approximately 10 inches long, and used the wire, to squeeze the pipe down to the desired 2.5 side on the smaller end. I cut both ends straight, and trued on a band saw.

I took a piece of white paper and held it up to the turbo outlet housing and rubbed along the flange to make a paper gasket outline. I cut it out and transferred to the flat steel. I plasma cut the bulk of the center, cleaned it up a bit on the mill, and then welded the cone to the steel stock that has the opening of the flange on the hot side of the turbo, to make my own home - made down pipe stub.

Now, on to the pictures:

Sadly, this is all I was able to get done, but with the exception of drilling the holes and bolting it to the back of the turbo, this is most of the "to do" stuff I wanted to get done before I left the job.

I need to make gaskets, drill holes in the down pipe, and use my personal angle grinder to port the opening of the down pipe, and port the adapter for smooth flow out of the exhaust manifold and into the turbo housing.

Backtobasics

Well-Known Member

And now, to answer questions that I have overlooked.

For now, I am going to stick with what I have. If it all proves to work, I might do a 2nd version on a spare slant 6 I have lying around.That will be sweet. I'd go wIth a bigger turbo did I were you. Something in the 60 mm range

Good stuff. I plan on lower boost, 6 sounds like a decent number. I am still researching carb's abilities. A secondary option, is using a pulse width modulator, to raise and lower voltage, on an alky / gas injection system. We are toying with using this and a MAP sensor, to trigger a nozzle injection setup above carb, to add the additional fuel under boost. The low cost idea, is a washer fluid pump setup, that injects just before the impeller. While this would be far from ideal, I can't imagine it being any worse in terms of distribution then the woeful stock intake, woeful stock head, woeful stock compression, etcYou might want to enclose the carburetor in a box to minimize pressurization modifications.

Will the stock float stand up to boost?

Is the Dart Lite distributor compatible with running boost, the advance curve is very different from a "normal" slant.

The BOV could be as simple as a low pressure radiator cap (6 PSI) plumbed into the tubing.

Just a few thoughts from someone else that has considered such a thing.

I did not see anywhere how much psi you plan on running, I assume since it is on a budget maybe 6 pounds? I think if your running around 6 pounds you can get away without a BOV.

Not sure what you could do about timing. maybe weld up the advance slots to limit the advance? I know they have things to retard timing when boost comes on but this is a budget build.:finga:

I can't wait to see how this turns out.

I don't know how the Dart Lite distributor will come into play, if at all, yet. This may not have the stock distributor? The car started and ran, so I never got crazy into the distributors vacuum advance canister, etc.What are you planning to do for fuel and timing?

Good info. I built the down pipe to 2.5 for ease of connecting to existing exhaust, but it wouldn't be too hard to open up to 3 inches. The stock manifold opening is so small, I am not sure it will make a huge difference either way. The way I see it, the little exhaust opening coupled with the small turbo housing are probably going to be the limitations on the horsepower of this build.Hey Backtobasics, awesome thread. All of a sudden /6's don't sound so bad after all. Just my 2 cents on the downpipe-2.5 inches may be a little too small, especially if you're gonna have a crush-bend exhaust made for the car. In my experience with imports, turbo engines don't like back pressure and the bigger/shorter exhausts work best. Just to give you an idea, I run a 2.5 inch exhaust on my all motor civic and my buddy has an rb20det in his 240sx with a 3 inch downpipe, 3 inch mandrel bent pipe going into a dynomax bullet and dumping right before the rear axle. Just my 2 cents. Keep up the great work!!!

Sadly, this is all I was able to get done, but with the exception of drilling the holes and bolting it to the back of the turbo, this is most of the "to do" stuff I wanted to get done before I left the job.

I need to make gaskets, drill holes in the down pipe, and use my personal angle grinder to port the opening of the down pipe, and port the adapter for smooth flow out of the exhaust manifold and into the turbo housing.

I believe that that's a super-nice solution to a really difficult problem. I think you should celebrate at a steak house with a nice filet mignon to honor this piece of excellent craftsmanship!

If this is any indication of your prowess as a fabricator, I don't think the rest if this build will offer ANY significant challenges to you!

That's an amazing piece of work; Congratlations!!!:hello1:

Backtobasics

Well-Known Member

Dear Gawd Bill, what are you doing up at this hour? I am only awake cause they pay me to be here, and you seem to be up at all hours?!!!

I don't fancy myself a fabricator. The nice shop tools help, but I believe all of this could be done at home with basic tools. I have a couple more nights, and then the night job is a DONE.

I don't fancy myself a fabricator. The nice shop tools help, but I believe all of this could be done at home with basic tools. I have a couple more nights, and then the night job is a DONE.

Dear Gawd Bill, what are you doing up at this hour? I am only awake cause they pay me to be here, and you seem to be up at all hours?!!!

I don't fancy myself a fabricator. The nice shop tools help, but I believe all of this could be done at home with basic tools. I have a couple more nights, and then the night job is a DONE.

I live alone, so nobody cares when I sleep. I'm retired, so I don't have to get up at any particular hour, and TV is better late at night than any other time (I watch a lot of "Law and Order and "Numbers" re-runs... LOL)

So, I stay up late...

Almost all my adult life, I worked nights (newspaper production,) so I'm used to it.

Face it; you have considerable skills as a fabricator. Not a bad realization to come to... lol!

73golddusterkid

Gold Duster Kid

Any updates?

jos51700

Green Bearing thread connoisseur

If you need it, I have plenty of scrap around and plenty of fab facilities available.

Might try one of the two-pickup triggers from a mid-80's Dodge Ram for timing needs. U-pull had two of 'em last time I was there. Time one trigger for boost, one for not, with a boost switch to change them.

And you can boost reference the stock mechanical pump at those low pressures. Piece of cake.

Good luck with it! I still have my "Cobra" carb enclosure for my Dart. I need to get cracking on that!

Might try one of the two-pickup triggers from a mid-80's Dodge Ram for timing needs. U-pull had two of 'em last time I was there. Time one trigger for boost, one for not, with a boost switch to change them.

And you can boost reference the stock mechanical pump at those low pressures. Piece of cake.

Good luck with it! I still have my "Cobra" carb enclosure for my Dart. I need to get cracking on that!

SirDan

Well-Known Member

And you can boost reference the stock mechanical pump at those low pressures. Piece of cake.

Could you provide more info on doing that? I would like to know and I bet the original poster would benefit from knowing.

Can't wait to see more of this build, I hope it is not on the backburner.

jos51700

Green Bearing thread connoisseur

Could you provide more info on doing that? I would like to know and I bet the original poster would benefit from knowing.

Can't wait to see more of this build, I hope it is not on the backburner.

The mechanical pump has a breather hole on the body, and part of the function besides venting is that mechanical fuel pressure is regulated according to atmospheric pressure (as if carbureted cars aren't rich enough at high altitude, who wants the pump over-pumping?).

Drill and tap carefully for a pipe-thread hose nipple and connect to boost above the carb. At lower boost pressure it can't overload the pump. At higher pressure (at 8+ I'd watch it carefully for awhile) it may rupture the diaphragm.

Attached is the instructions from Paxton for Rustangs, but I found similar instructions at one time for the Mr. Norm's kit, and they were similar. Page 19.

Attachments

Backtobasics

Well-Known Member

Its not dead, just sitting in the garage.

Admittedly, I am strongly considering abandoning the 6 and moving to small block combo. I have lead local on 360/727/8.75 A body with big bolt pattern. Really leaning towards picking it up, pulling out the running gear, and parting rest. I want disk brakes on the Dart before I drive consistently, and the new job is close enough that MPG is kinda moot. I miss the 4 barrel kick, miss the older hot rod feel.

I dunno. To top it off, the Mustang that I am doing paint and body work just showed up today.

Admittedly, I am strongly considering abandoning the 6 and moving to small block combo. I have lead local on 360/727/8.75 A body with big bolt pattern. Really leaning towards picking it up, pulling out the running gear, and parting rest. I want disk brakes on the Dart before I drive consistently, and the new job is close enough that MPG is kinda moot. I miss the 4 barrel kick, miss the older hot rod feel.

I dunno. To top it off, the Mustang that I am doing paint and body work just showed up today.

Backtobasics

Well-Known Member

Bringing it back from the dead. The city decided it would look better in the front yard, then out back, under the deck.

The car needed some work to wake it up: Carb (RockAuto), plugs, wires, cap, rotor, coil. Fixed tail light wiring. Replaced headlight switch. The car is now running and driving. Drove it to work today.

I am torn, between small block, big block, or boosted 6. Right now, it it is nice to drive it frequently. Updates to come.

The car needed some work to wake it up: Carb (RockAuto), plugs, wires, cap, rotor, coil. Fixed tail light wiring. Replaced headlight switch. The car is now running and driving. Drove it to work today.

I am torn, between small block, big block, or boosted 6. Right now, it it is nice to drive it frequently. Updates to come.

Backtobasics

Well-Known Member

I am kicking myself for letting this slip away. I had forgotten how far long I was.

Oh well.

New idea that came to me....

Oh well.

New idea that came to me....

Backtobasics

Well-Known Member

The supercharger was given to me. I am going to see if I can make it draw-thru. I am going to pick up some plate steel at metal by the foot as an adapter / base. It needs to be big enough to bolt the supercharger to, and then bolt to the intake manifold. I have a 2 barrel unit that I might use instead. I am going to run round tube U off the back of the supercharger, and position the carburetor next to the body of the supercharger.

Backtobasics

Well-Known Member

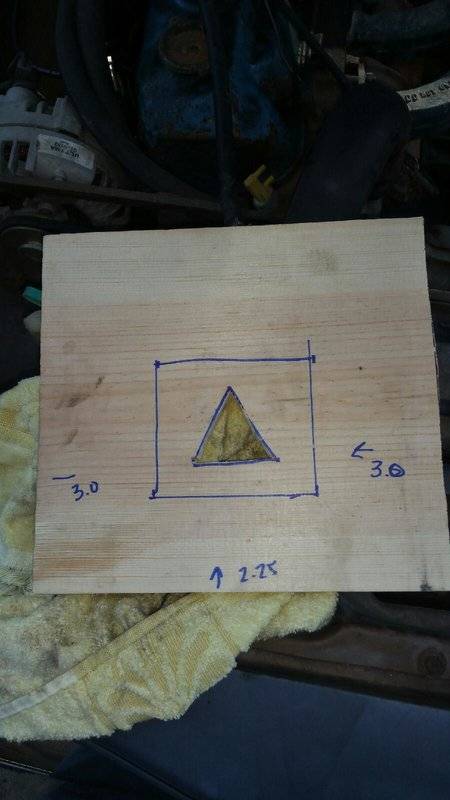

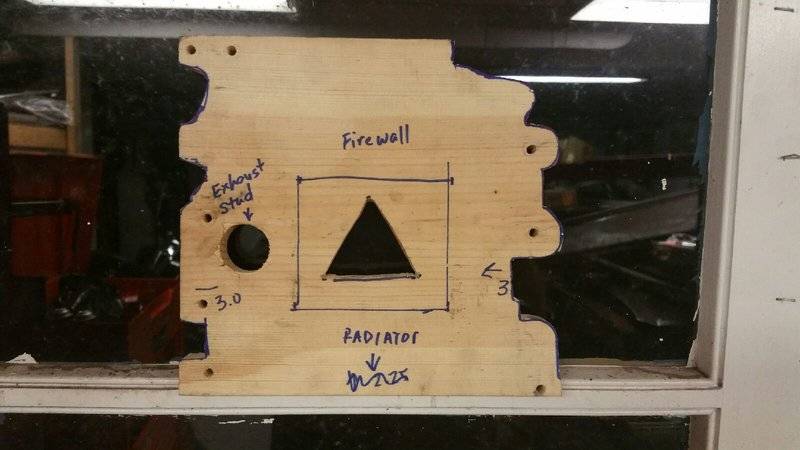

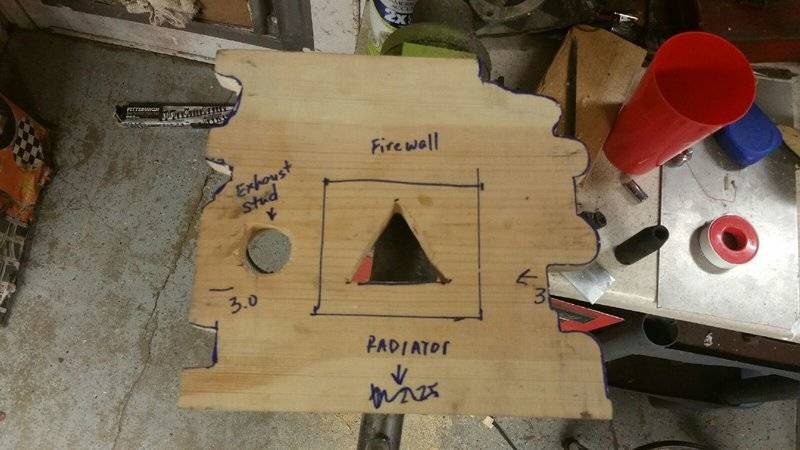

Mock up pictures for the adapter to between the intake manifold and the supercharger.

Last edited:

Backtobasics

Well-Known Member

I pulled the carb and studs. The supercharger appears that it will clear the dipstick nicely. I might have to do a a little trimming of the choke well on the exhaust manifold, and make a small extension for the bolt and nut that protrude through the intake manifold from the exhaust. I will need to build an extension to the front of the supercharger for the belt drive. I used a piece of wood as my template, and measured and mocked up what will bolt to the intake, and act as the base for the supercharger itself. I need to pick up some metal, and build the adapter. Once that is set up and ready, I will build a stand that uses the motor mount to the bottom of the super charger, as a support for the additional weight and leverage that will be hanging off the side of the engine.

Backtobasics

Well-Known Member

The triangle in the wood is an approximate shape of the opening on the underside of the supercharger, that is close to the size of the 1 barrel opening. It will allow me to position the discharge of the supercharger right above the opening of the intake.

I have a 2 barrel intake that I have had sitting for some time. I toyed with using that under the supercharger, but I am keeping the 1 barrel for now, because the discharge of the s/c is about the same as the 1 barrel, plus it saves me breaking the intake and exhaust apart, inviting an exhaust leak. To be honest, I don't know in a forced induction application of this size, that there will be a difference in intake performance between 1 and 2 barrel if the outlet of the s/c is smaller than the 2 barrel. Since I am going to be draw-thru, the 1 barrel might be too small, at which time I can go larger.

I have a 2 barrel intake that I have had sitting for some time. I toyed with using that under the supercharger, but I am keeping the 1 barrel for now, because the discharge of the s/c is about the same as the 1 barrel, plus it saves me breaking the intake and exhaust apart, inviting an exhaust leak. To be honest, I don't know in a forced induction application of this size, that there will be a difference in intake performance between 1 and 2 barrel if the outlet of the s/c is smaller than the 2 barrel. Since I am going to be draw-thru, the 1 barrel might be too small, at which time I can go larger.

Backtobasics

Well-Known Member

More Progress:

I used anti-seize on the bottom of a core carburetor to make a template that will match the intake manifold...

I used anti-seize on the bottom of a core carburetor to make a template that will match the intake manifold...

Backtobasics

Well-Known Member

Positions the template at the base of the supercharger outlet

Backtobasics

Well-Known Member

Stages of the adapter template, from initial cut out, to final version with carb positioning and drilled for fasteners

Backtobasics

Well-Known Member

Eliminating the factory air by pass that is built into the supercharger.

Backtobasics

Well-Known Member

Planned layout of carburetor next to supercharger, in front of master cylinder. I have ordered a 2.5 tight bend that will connect to the bottom of the carburetor to the tubing that snakes around the back of the supercharger.

From turbo to supercharge. Commitment issues? Just kidding. Great work! Can't wait to see how it turns out.

CichliDart

Well, where is it now?

The supercharger was given to me. I am going to see if I can make it draw-thru. I am going to pick up some plate steel at metal by the foot as an adapter / base. It needs to be big enough to bolt the supercharger to, and then bolt to the intake manifold. I have a 2 barrel unit that I might use instead. I am going to run round tube U off the back of the supercharger, and position the carburetor next to the body of the supercharger.

Any idea what this came from?

Subscribed!

-