72Dart6pack

Harder Better Faster Stronger.

I recently bought Comp Cam 1622-16

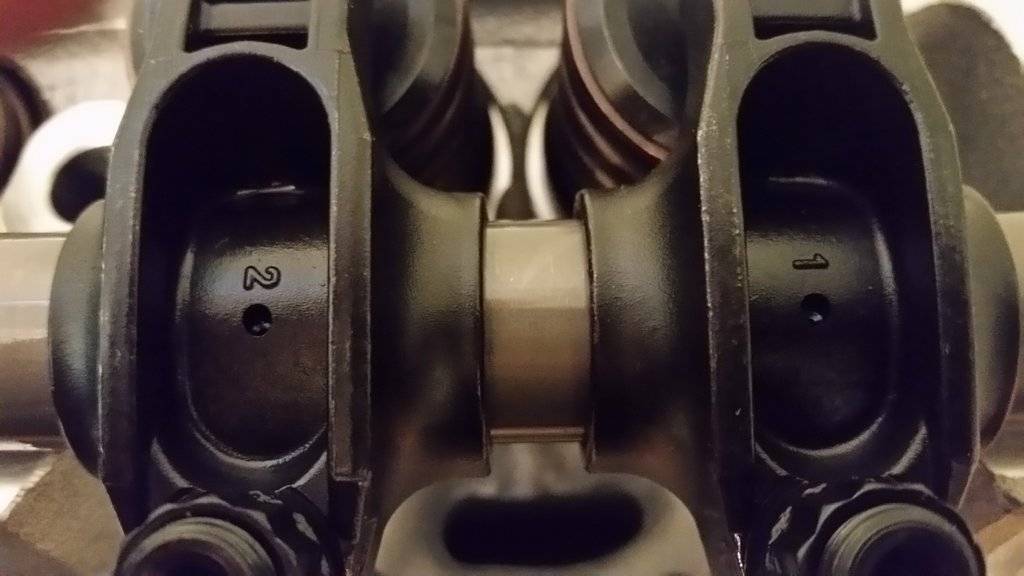

Pro Magnum rockers. I have 8 rocker arms with a #1 & 8 with the #2 cast in to them as in the photo. Is one number for intake & the other number for exhaust? If so which is which? They came on the shafts in no particular order or reason. Can anyone help me out? Thanks!

Pro Magnum rockers. I have 8 rocker arms with a #1 & 8 with the #2 cast in to them as in the photo. Is one number for intake & the other number for exhaust? If so which is which? They came on the shafts in no particular order or reason. Can anyone help me out? Thanks!