SS Lancer

Well-Known Member

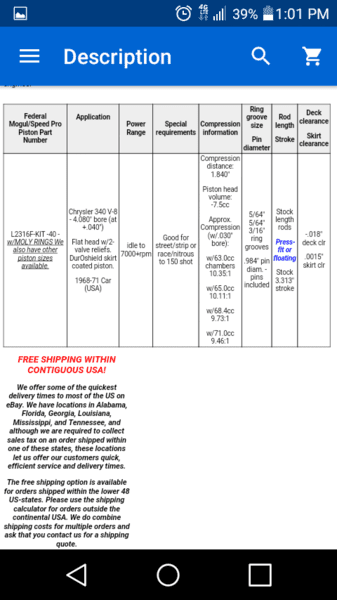

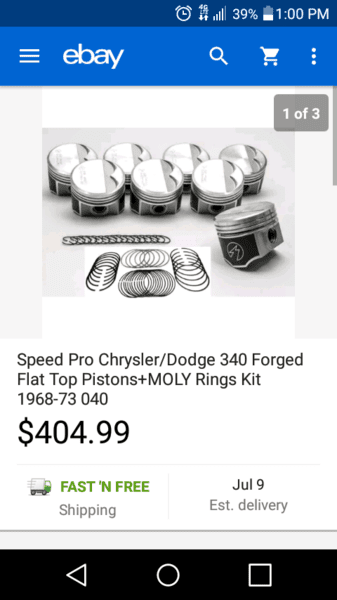

I have a 40 over 340 block 4.080 - and cant find pistons with compression level I want without having them custom made I wanted 11 or 11.50.1 compression and the most I can find are these but these slugs are heavy .

What gasket thickness do you suppose they are using to get these compression levels ???

What gasket thickness do you suppose they are using to get these compression levels ???