Its is hard to find info on theses car, But this is a great post for info, Lets keep it going. I am helping with a SS barracuda build and trying to find info is not the easiest thing thats for sure. Looking for front rotors and alternator number, correct brake master offset bracket. Original master cylinder brake hoses to make the lines. How did they run the battery cable? I have a bunch more...

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

SS/B Barracuda project

- Thread starter SSing

- Start date

-

I also talked to HemiEddie on those headers He said they had no parts number on them, from my research all Hooker headers had numbers. What do you guys think?

SSing

Well-Known Member

Did you talk to Hemi Eddy on eBay that says he has an original pair of these headers for sale?

No, my mail address got blocked...

Of cause there are guys out there who can tell for sure. No rocket science here.

Friends or not... I started this thread to get info on some details I wasn´t sure about, and when I keep asking questions and get no respond, I see no point in continuing.

My big source of info, has turned out to be articles from old car magazines, and not many issues left now. Not saying the car is going to be correct in every little detail, but very close too... in this case, nothing beats a picture from 1968...

SSing

Well-Known Member

It seems some people still drop by and, well I don´t know how it works, but there have been a few new views it seems.

If this is the case and with respect for your interest in the build, I´ll show a few picks of what´s going on.

I´m starting where I left, with this article about Ramchargers, from 1969. Jere Stahl is Technical Editor so I´ll go with what is says.

If this is the case and with respect for your interest in the build, I´ll show a few picks of what´s going on.

I´m starting where I left, with this article about Ramchargers, from 1969. Jere Stahl is Technical Editor so I´ll go with what is says.

SSing

Well-Known Member

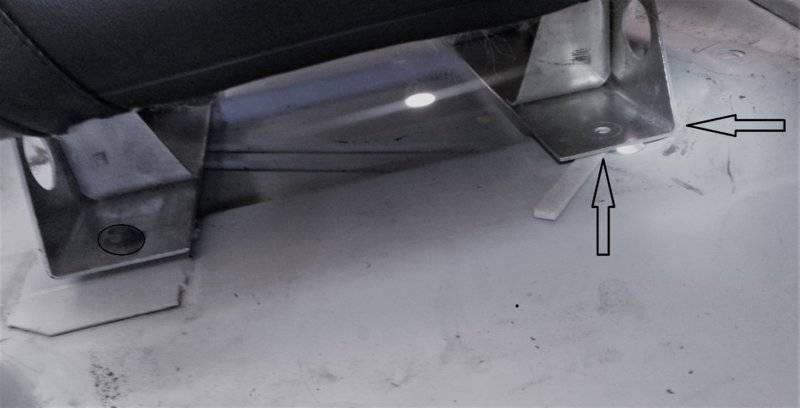

Seat Brackets… now let´s see…

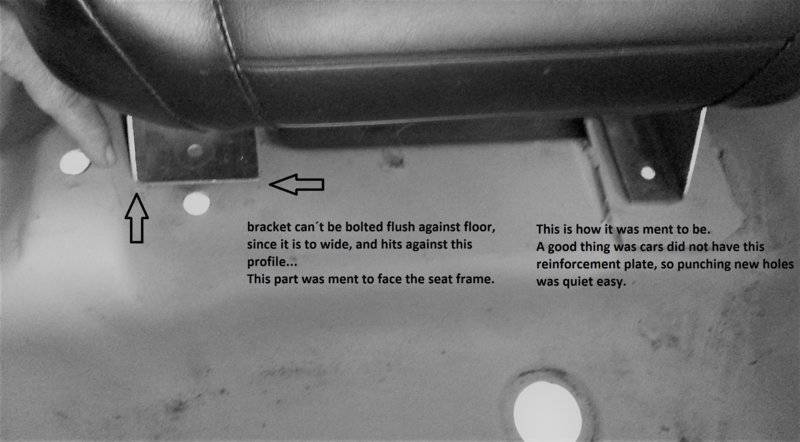

No, you can´t make these brackets fit properly.

I think vendor who made these brackets messed up…

Look at the pics and see for yourself.

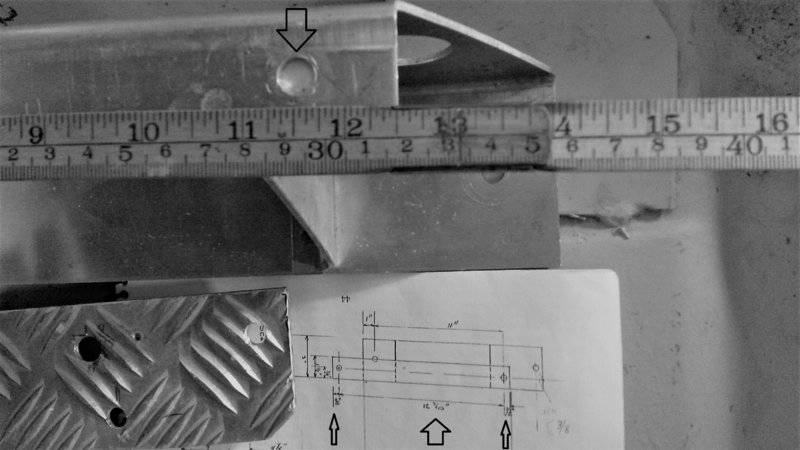

Blueprint in the ´68 SS Hemi Guide says 12 3/10” between holes. Same measurement as in the floor. This narrower part of the bracket was meant to face towards floor. Not like Hurst had to bolt them, because Vendor made them wrong.

Measurement between holes in bracket is some 11 9/16”.

Alu stripe to left is something I use between bracket and seat frame.

Holes should have been drilled half an inch from end.

Another picture of what went wrong. Holes should have been drilled a little further apart in the bracket.

Distance between holes in floor is 12 3/10” like blueprint says bracket should have had.

Time and money was ruling this whole project now, once it was on the go...

"Just bolt the darn seats to the floor".

No, you can´t make these brackets fit properly.

I think vendor who made these brackets messed up…

Look at the pics and see for yourself.

Blueprint in the ´68 SS Hemi Guide says 12 3/10” between holes. Same measurement as in the floor. This narrower part of the bracket was meant to face towards floor. Not like Hurst had to bolt them, because Vendor made them wrong.

Measurement between holes in bracket is some 11 9/16”.

Alu stripe to left is something I use between bracket and seat frame.

Holes should have been drilled half an inch from end.

Another picture of what went wrong. Holes should have been drilled a little further apart in the bracket.

Distance between holes in floor is 12 3/10” like blueprint says bracket should have had.

Time and money was ruling this whole project now, once it was on the go...

"Just bolt the darn seats to the floor".

Last edited:

SSing

Well-Known Member

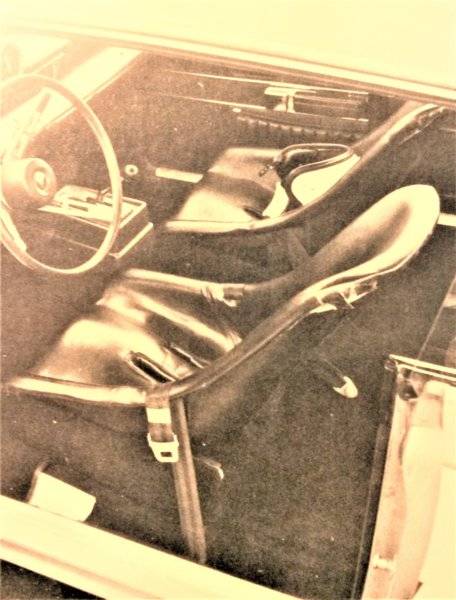

Well, I´m going to rant some more about these alu. seat brackets that I doubt was made for the A-100 seats used.

I think everything was planned and checked as to how these cars was to be build, prior to the final decision Chrysler made to go ahead and do it. It means Tarozzi or whoever made the blueprint did not have the A-100 seat in mind at the time. This is late 1967 I suppose.

A look at the seat used in the Mule Car seems to be the seat used in the Porsche Speedster and looks like this.

Seat bracket looks to be covered by something, but could very well be something similar to what they than looked like.

Than something happened, and Chrysler change their mind about the seat and used the A-100 seat. Maybe weight was already down enough. Maybe cost of the Porsche seat was to high??

Again, the wide part of the bracket does not fit the seat rail. But if you look at the ´65 SS cars, wide side is up and narrow side of the bracket is bolted to floor.

Pic of what the Speedster seat looks underneath.

The narrow part of the bracket do fit the seat rail, but not in the utter nuts, so not in an optimal way. Probably by pure coincidence, or by a last minute change at the vendor.

Enough of this now, since this will not change the way I´m going to bolt these seats. Just would interesting to know how all this came to be.

I think everything was planned and checked as to how these cars was to be build, prior to the final decision Chrysler made to go ahead and do it. It means Tarozzi or whoever made the blueprint did not have the A-100 seat in mind at the time. This is late 1967 I suppose.

A look at the seat used in the Mule Car seems to be the seat used in the Porsche Speedster and looks like this.

Seat bracket looks to be covered by something, but could very well be something similar to what they than looked like.

Than something happened, and Chrysler change their mind about the seat and used the A-100 seat. Maybe weight was already down enough. Maybe cost of the Porsche seat was to high??

Again, the wide part of the bracket does not fit the seat rail. But if you look at the ´65 SS cars, wide side is up and narrow side of the bracket is bolted to floor.

Pic of what the Speedster seat looks underneath.

The narrow part of the bracket do fit the seat rail, but not in the utter nuts, so not in an optimal way. Probably by pure coincidence, or by a last minute change at the vendor.

Enough of this now, since this will not change the way I´m going to bolt these seats. Just would interesting to know how all this came to be.

ns1rm21

Well-Known Member

- Joined

- Feb 22, 2008

- Messages

- 655

- Reaction score

- 624

Interesting....

I used the repop brackets but I don’t remember who’s they are. To me they did fit the contour of the floor and the seat but I did need to relocate the holes. I welded up the holes....drilled new ones and I was done. Sorry your having these problems.

I used the repop brackets but I don’t remember who’s they are. To me they did fit the contour of the floor and the seat but I did need to relocate the holes. I welded up the holes....drilled new ones and I was done. Sorry your having these problems.

SSing

Well-Known Member

Interesting....

I used the repop brackets but I don’t remember who’s they are. To me they did fit the contour of the floor and the seat but I did need to relocate the holes. I welded up the holes....drilled new ones and I was done. Sorry your having these problems.

Well, not a problem really. Just an observation. What you did, what I´m going to do and what Hurst did is basically the same thing. Put the parts together, fitting or not, PUNCH (yes according to a reliable source) holes in the floor and bolt the seat tight.

My observations are correct, but how it all came to be this way, no idea of cause... but yes interesting.

SSing

Well-Known Member

A couple more pics of the bucket seat less upholstery from the Porsche 356 Speedster.

SSing

Well-Known Member

Yes, you said that, but what I meant was the guys at Hurst fixed whatever problem occurred.

As for the seat brackets, I´m quite sure Hurst did not touched them in terms of drilling new holes…

As for the seat brackets, I´m quite sure Hurst did not touched them in terms of drilling new holes…

SSing

Well-Known Member

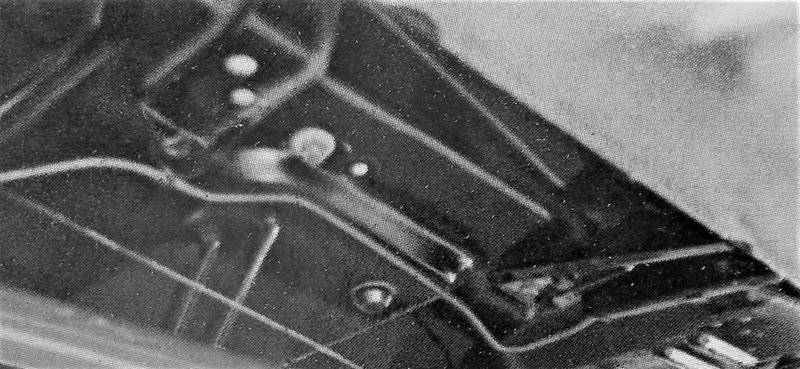

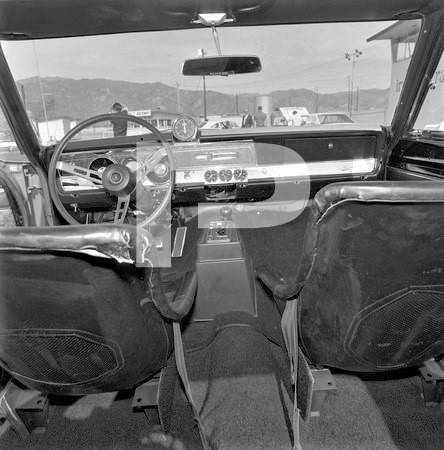

One would think at least one bolt and a hole in the floor should match, but due to the width of the bracket and how they are bolted to the seat, it rides on the tunnel and profile on witch bench seat is to be bolted. But I let the pictures show what I´m trying to explain.

Here is how bracket is bolted to the seat.

the rail along the side of the seat is lower than rail going across front and back of the seat. This means alu bracket is not bolted level to seat, since rear of bracket is bolted in the rail going across of the seat in the back. Anyway this give holes (to floor) in the bracket a certain "bolt pattern" witch is important.

I use an alu plate to level bracket to the seat. Since my project is as raced first season, this my very well have been done to move seat in a more comfortable position. I can now move seat on brackets without unbolt the brackets to the floor if I want to move seat forward.

This is how Hurst bolted the seat. Front right bolt in original hole in floor.

"Someone" very recently told me a spacer/pad may have been used. (No all cars may have been alike as we know) I assume this is way. To clear left side (right on photo) of the bracket to the floor profile.

A new hole just behind and to the right (left in pic)of the original hole (arrows) in floor was punched. See last picture.

Very early picture of driver side bracket showing inner edge of bracket is not bolted down in carpet. Spacer is used?

This also show front of (left) bracket is tucked up in seat as described in first pic.

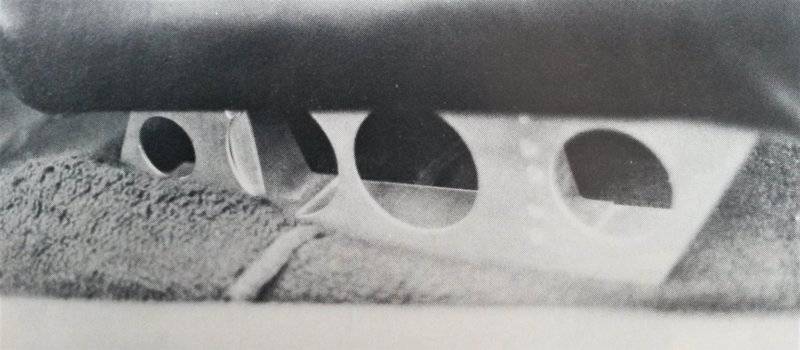

This is driver side left bracket mounting holes seen from underneath.

This very early picture shows exactly that. The larger hole in the center of the reinforcement is original hole in floor. Next empty hole just behind and to the right was done at Hurt (compare second pic above) The owner of this car has moved the seat back 2 some inches.

Also looks like a new hole in the alu bracket has been drilled in the rear of the bracket to use reinforcement in the floor.

Here is how bracket is bolted to the seat.

the rail along the side of the seat is lower than rail going across front and back of the seat. This means alu bracket is not bolted level to seat, since rear of bracket is bolted in the rail going across of the seat in the back. Anyway this give holes (to floor) in the bracket a certain "bolt pattern" witch is important.

I use an alu plate to level bracket to the seat. Since my project is as raced first season, this my very well have been done to move seat in a more comfortable position. I can now move seat on brackets without unbolt the brackets to the floor if I want to move seat forward.

This is how Hurst bolted the seat. Front right bolt in original hole in floor.

"Someone" very recently told me a spacer/pad may have been used. (No all cars may have been alike as we know) I assume this is way. To clear left side (right on photo) of the bracket to the floor profile.

A new hole just behind and to the right (left in pic)of the original hole (arrows) in floor was punched. See last picture.

Very early picture of driver side bracket showing inner edge of bracket is not bolted down in carpet. Spacer is used?

This also show front of (left) bracket is tucked up in seat as described in first pic.

This is driver side left bracket mounting holes seen from underneath.

This very early picture shows exactly that. The larger hole in the center of the reinforcement is original hole in floor. Next empty hole just behind and to the right was done at Hurt (compare second pic above) The owner of this car has moved the seat back 2 some inches.

Also looks like a new hole in the alu bracket has been drilled in the rear of the bracket to use reinforcement in the floor.

SSing

Well-Known Member

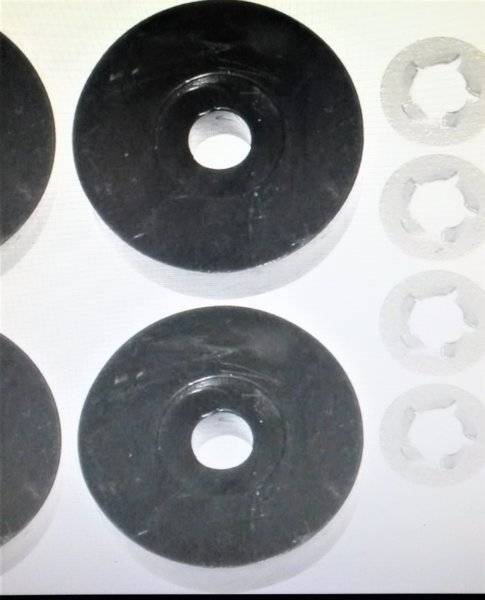

And this is what the seat mounting pads look like.

As I understand Chrysler used these for the bench seat mounting in their production cars. I have never seem them before.

Picture is taken from Classic Industries.

As I understand Chrysler used these for the bench seat mounting in their production cars. I have never seem them before.

Picture is taken from Classic Industries.

famous bob

mopar misfit

And this is what the seat mounting pads look like.

As I understand Chrysler used these for the bench seat mounting in their production cars. I have never seem them before.

Picture is taken from Classic Industries.

View attachment 1715232665

NOT FACTORY CORRECT BUT SHOCK ABSORBER RUBBERS WORK FOR THAT TOO.

HemiSSDart

Dartus Interuptus

And this is what the seat mounting pads look like.

As I understand Chrysler used these for the bench seat mounting in their production cars. I have never seem them before.

Picture is taken from Classic Industries.

View attachment 1715232665

I have several of those spacers that I found under seats of other A-Body's, they are kind of a fiberglass/plastic mix. My Hemi Dart is just going to be a mix of old race parts and hacked-up junk that people used to make these cars light and fast without thought to the way it looked...

SSing

Well-Known Member

NOT FACTORY CORRECT BUT SHOCK ABSORBER RUBBERS WORK FOR THAT TOO.

Yes, that´s what you normally do on your old Hot Rod, but I found them on Eb for $14 some and didn´t know the height so almost fun to order something this cheap

SSing

Well-Known Member

Got to spend some time in the garage on Sunday. Funny when you think you achieved something great just bolting up a bucket seat. But in this case it has taken some figuring before I finally drilled those holes. And when I look at it now I get this good yes-that's-how-it-was-done feeling…

Someone messed up the aluminium brackets to a point where almost none of the original holes in floor could be used, witch is an achievement in it self. Front right bolt can use existing hole though.

As for the bolts I´m not sure the ordinary 1,25" were used other than fasten the seat enough for the driver to pick up the car. The utter two bolts I´m sure have to be longer as I in order to get the seat (backrest) in line with the door jambs, had to drill through the u-bracket used as a reinforcement for the seat underneath the floor.

This I sure can vary from car to car, and if I had chosen to turn the seat just a hair, drill would have missed this bracket.

Since the GTS base modell came with bench seat, there was no reinforcement needed. I hope the BB Formula S was the same or I screwed this up.

I suppose body plugs were used since ordinary holes weren´t used, but you never know...

Someone messed up the aluminium brackets to a point where almost none of the original holes in floor could be used, witch is an achievement in it self. Front right bolt can use existing hole though.

As for the bolts I´m not sure the ordinary 1,25" were used other than fasten the seat enough for the driver to pick up the car. The utter two bolts I´m sure have to be longer as I in order to get the seat (backrest) in line with the door jambs, had to drill through the u-bracket used as a reinforcement for the seat underneath the floor.

This I sure can vary from car to car, and if I had chosen to turn the seat just a hair, drill would have missed this bracket.

Since the GTS base modell came with bench seat, there was no reinforcement needed. I hope the BB Formula S was the same or I screwed this up.

I suppose body plugs were used since ordinary holes weren´t used, but you never know...

Last edited:

famous bob

mopar misfit

A couple more pics of the bucket seat less upholstery from the Porsche 356 Speedster.

View attachment 1715229198

View attachment 1715229199

Are these seats available any where/ are they wider in the but area than the little boy lite weight poly seats of today ?

SSing

Well-Known Member

Well I don´t know much about these seats other than what I have seen on picks and for the size I recon they are tight like most thing in a sports car like this...Are these seats available any where/ are they wider in the but area than the little boy lite weight poly seats of today ?

SSing

Well-Known Member

Mirror Delete Plate.

There is a $300.00 difference here. Not very obvious, but repop to the left has slightly smother edges.

Original is a hair longer, but the obvious difference is back side.

Fastener for the original plate is this nut that looks to made of tin metal and has a washer to it and should´t be to hard to find. Gasket though I guess you can forget to even look for.

In all this is a very good copy and it was sheer luck I found this NOS Plate, not really looking for one, at a very good price witch will makes it easier to get rid of repop piece.

There is a $300.00 difference here. Not very obvious, but repop to the left has slightly smother edges.

Original is a hair longer, but the obvious difference is back side.

Fastener for the original plate is this nut that looks to made of tin metal and has a washer to it and should´t be to hard to find. Gasket though I guess you can forget to even look for.

In all this is a very good copy and it was sheer luck I found this NOS Plate, not really looking for one, at a very good price witch will makes it easier to get rid of repop piece.

SSing

Well-Known Member

POST 331

Well, I´m going to rant some more about these alu. seat brackets that I doubt was made for the A-100 seats used.

I think everything was planned and checked as to how these cars was to be build, prior to the final decision Chrysler made to go ahead and do it. It means Tarozzi or whoever made the blueprint did not have the A-100 seat in mind at the time. This is late 1967 I suppose.

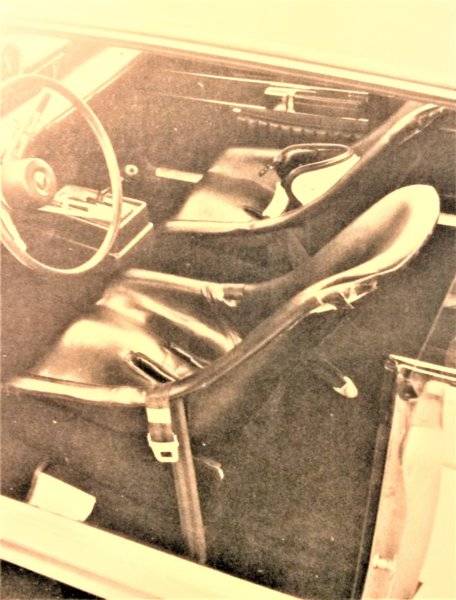

A look at the seat used in the Mule Car seems to be the seat used in the Porsche Speedster and looks like this.

Seat bracket looks to be covered by something, but could very well be something similar to what they than looked like.

Than something happened, and Chrysler change their mind about the seat and used the A-100 seat. Maybe weight was already down enough. Maybe cost of the Porsche seat was to high??

Again, the wide part of the bracket does not fit the seat rail. But if you look at the ´65 SS cars, wide side is up and narrow side of the bracket is bolted to floor.

Pic of what the Speedster seat looks underneath.

The narrow part of the bracket do fit the seat rail, but not in the utter nuts, so not in an optimal way. Probably by pure coincidence, or by a last minute change at the vendor.

Enough of this now, since this will not change the way I´m going to bolt these seats. Just would interesting to know how all this came to be.

SURE ENOUGH...

This picture from 1968 and the Mule Car explains the mystery of the Aluminum Seat Brackets, and show how the brackets were meant to be bolted to the Porsche seat. Wide side up.

Aluminum Seat Bracket mystery. Check.

Source: Peterson Publishing photo archive "Woodward Garage"

Well, I´m going to rant some more about these alu. seat brackets that I doubt was made for the A-100 seats used.

I think everything was planned and checked as to how these cars was to be build, prior to the final decision Chrysler made to go ahead and do it. It means Tarozzi or whoever made the blueprint did not have the A-100 seat in mind at the time. This is late 1967 I suppose.

A look at the seat used in the Mule Car seems to be the seat used in the Porsche Speedster and looks like this.

Seat bracket looks to be covered by something, but could very well be something similar to what they than looked like.

Than something happened, and Chrysler change their mind about the seat and used the A-100 seat. Maybe weight was already down enough. Maybe cost of the Porsche seat was to high??

Again, the wide part of the bracket does not fit the seat rail. But if you look at the ´65 SS cars, wide side is up and narrow side of the bracket is bolted to floor.

Pic of what the Speedster seat looks underneath.

The narrow part of the bracket do fit the seat rail, but not in the utter nuts, so not in an optimal way. Probably by pure coincidence, or by a last minute change at the vendor.

Enough of this now, since this will not change the way I´m going to bolt these seats. Just would interesting to know how all this came to be.

SURE ENOUGH...

This picture from 1968 and the Mule Car explains the mystery of the Aluminum Seat Brackets, and show how the brackets were meant to be bolted to the Porsche seat. Wide side up.

Aluminum Seat Bracket mystery. Check.

Source: Peterson Publishing photo archive "Woodward Garage"

Last edited:

SSing

Well-Known Member

INNER FENDER HAMMERING

Once I found good pics of what it looked like, it wasn´t that hard to do it.

Key words here are crude and brutal and not to over work it, but rather give the inner fender that final BFH-kiss to make it look real bad.

Cut inner fender and fold to free shock absorber bracing.

Heat and hammer away.

And finally weld shut.

Not sure the bar to support the sa bracing was necessary though...

Once I found good pics of what it looked like, it wasn´t that hard to do it.

Key words here are crude and brutal and not to over work it, but rather give the inner fender that final BFH-kiss to make it look real bad.

Cut inner fender and fold to free shock absorber bracing.

Heat and hammer away.

And finally weld shut.

Not sure the bar to support the sa bracing was necessary though...

ns1rm21

Well-Known Member

- Joined

- Feb 22, 2008

- Messages

- 655

- Reaction score

- 624

That looks real good. I have seen several pictures of how this was done and I have seen two different ways. One way is the way you did it......by slicing the inner fenderwell and moving it up. The other way was buy heating up the area including the actual shock mount and beating it down. Your way is the correct way and I think the workers just got lazy I the third batch of cars.

Hemisurfer

Active Member

Chrysler’s intention to use Porsche Speedster seats in a limited production run for Super Stock was dubious and pushing the intention of the production available rules that pertained to Super Stock, after seeing it maybe...the NHRA said no way...so Chrysler revived the lightweight seats from 64-65 that the NHRA had already blessed years earlier....Maybe....POST 331

Well, I´m going to rant some more about these alu. seat brackets that I doubt was made for the A-100 seats used.

I think everything was planned and checked as to how these cars was to be build, prior to the final decision Chrysler made to go ahead and do it. It means Tarozzi or whoever made the blueprint did not have the A-100 seat in mind at the time. This is late 1967 I suppose.

A look at the seat used in the Mule Car seems to be the seat used in the Porsche Speedster and looks like this.

View attachment 1715288601

Seat bracket looks to be covered by something, but could very well be something similar to what they than looked like.

Than something happened, and Chrysler change their mind about the seat and used the A-100 seat. Maybe weight was already down enough. Maybe cost of the Porsche seat was to high??

Again, the wide part of the bracket does not fit the seat rail. But if you look at the ´65 SS cars, wide side is up and narrow side of the bracket is bolted to floor.

Pic of what the Speedster seat looks underneath.

View attachment 1715288602

The narrow part of the bracket do fit the seat rail, but not in the utter nuts, so not in an optimal way. Probably by pure coincidence, or by a last minute change at the vendor.

Enough of this now, since this will not change the way I´m going to bolt these seats. Just would interesting to know how all this came to be.

SURE ENOUGH...

This picture from 1968 and the Mule Car explains the mystery of the Aluminum Seat Brackets, and show how the brackets were meant to be bolted to the Porsche seat. Wide side up.

Aluminum Seat Bracket mystery. Check.

View attachment 1715288594

Source: Peterson Publishing photo archive "Woodward Garage"

SSing

Well-Known Member

Chrysler’s intention to use Porsche Speedster seats in a limited production run for Super Stock was dubious and pushing the intention of the production available rules that pertained to Super Stock, after seeing it maybe...the NHRA said no way...so Chrysler revived the lightweight seats from 64-65 that the NHRA had already blessed years earlier....Maybe....

Yes, could be. But on the other hand Chrysler got away with the cut wheel wells on the Dart, and a lot of weird things and odd parts, since it was just this… a production car…

Well I don´t know, but my guess is cost. These German stuff probably wasn´t cheap.

-