Red_Duster

Well-Known Member

Good morning all,

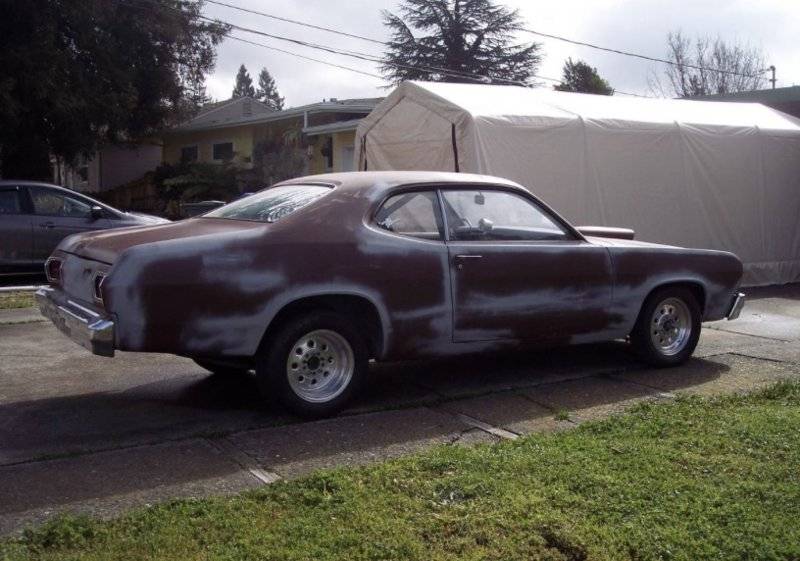

Starting a dedicated build thread for my current project- 1974 Plymouth Duster 440/727 build. This will never be a show car, or restoration. Its just going to be fun weekend car and make the occasional pass at the strip.

I picked up the car in Santa Rosa, CA from a nice older fella' named Stan. Took a little drive out to see it, and after crawling around it for an hour or so, made the deal and went back the following Saturday to pick up with a trailer.

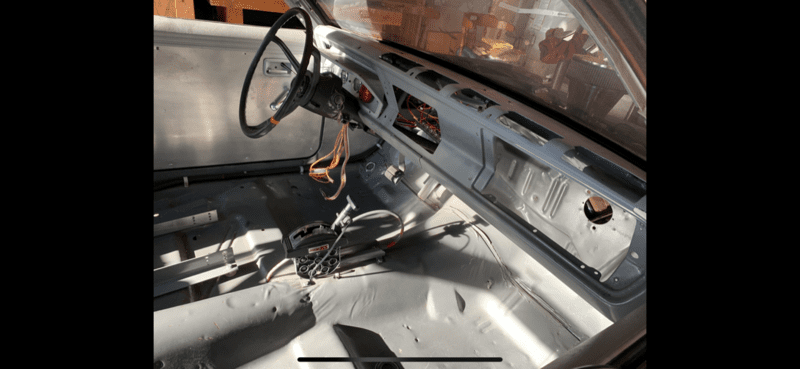

As it sat: Totally rust free '74 that Stan used to run up at Sear Point until parking it in '81. Zero interior (all aluminum panels) no gauges outside of water temp and oil pressure with an oil pressure light. 6 Point cage that already had the front points cut out, and a single drag bucket. Car already has an A-Body 8-3/4 with 4.56 spool. Trans is a reverse manual 727, 3000 rpm stall with a Turbo action shifter. Battery is relocated to trunk with the bare minimum wiring and a single wire alternator. Driveshaft loop and adjustable pinion snubber are still in the car.

The car came with a whole file of receipts for the 440 including the machine work. .30 over, balanced and blueprinted. Flat tops (didn't say CR). I have the cam card, and ill verify but I believe it was 296 with .577 lift. Sounds massive. Car originally had an air gap that was stolen while parked so currently has Eddy intake and 750 carb. Schumacher mounts, headers and mini-starter.

Along with the car came tons of parts boxes, including most of the interior, a complete wiring harness (and then some) original gauge cluster.

Also found a few time-slips from '80 for 12.08 @ 109.

Starting a dedicated build thread for my current project- 1974 Plymouth Duster 440/727 build. This will never be a show car, or restoration. Its just going to be fun weekend car and make the occasional pass at the strip.

I picked up the car in Santa Rosa, CA from a nice older fella' named Stan. Took a little drive out to see it, and after crawling around it for an hour or so, made the deal and went back the following Saturday to pick up with a trailer.

As it sat: Totally rust free '74 that Stan used to run up at Sear Point until parking it in '81. Zero interior (all aluminum panels) no gauges outside of water temp and oil pressure with an oil pressure light. 6 Point cage that already had the front points cut out, and a single drag bucket. Car already has an A-Body 8-3/4 with 4.56 spool. Trans is a reverse manual 727, 3000 rpm stall with a Turbo action shifter. Battery is relocated to trunk with the bare minimum wiring and a single wire alternator. Driveshaft loop and adjustable pinion snubber are still in the car.

The car came with a whole file of receipts for the 440 including the machine work. .30 over, balanced and blueprinted. Flat tops (didn't say CR). I have the cam card, and ill verify but I believe it was 296 with .577 lift. Sounds massive. Car originally had an air gap that was stolen while parked so currently has Eddy intake and 750 carb. Schumacher mounts, headers and mini-starter.

Along with the car came tons of parts boxes, including most of the interior, a complete wiring harness (and then some) original gauge cluster.

Also found a few time-slips from '80 for 12.08 @ 109.

Last edited: