I use a shop that does the dynamic, on vehicle, balancing and I'm one that thinks it is superior to the the modern style. They also do tire skimming. Whenever I have a vehicle tires skimmed and balanced at this shop I get an awesome ride.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Using mustang rotors for 4.5" bc

- Thread starter Longgone

- Start date

-

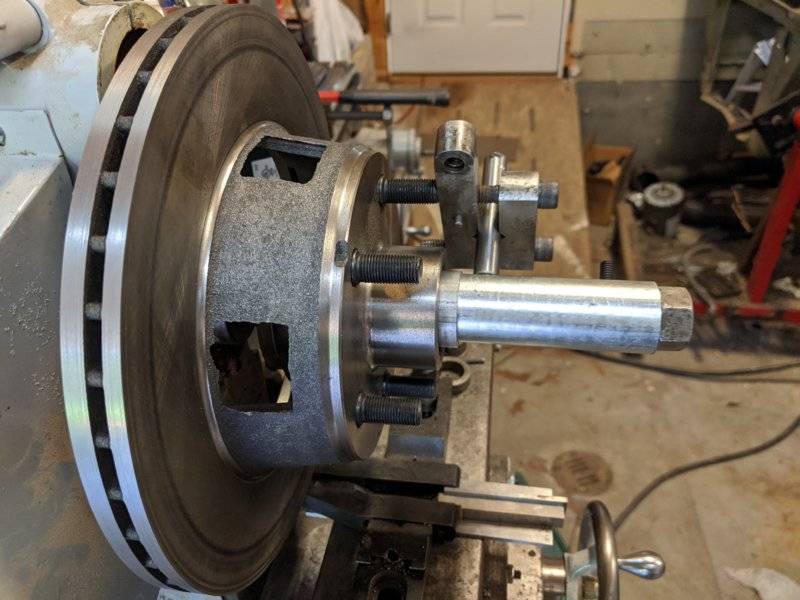

My lathe is a little too small to swing the 11.210" mustang rotors so I set it up in my mill on a rotary table.. I'll do the machining of the bearing/seal areas but will have to bring them to get the OD cut down. I'm including a photo or two of the measurements I've taken and the demensions I think are correct. My main question is the difference in the distance from the outside dust cup face and the inside of the rotor face. There is a difference of -.125" between the mustang rotor and the OEM rotor. What, if anything, should folks be concerned about?

Thanks

Fwiw, this is a rotor I machined to the specs above minus the OD reduction.

Last edited:

Just out of curiosity couldn't you just have the hubs and rotors drilled to 5x4.5 and put new studs in, seems simpler, ( I did not read all 11 pages so pardon if it was already addressed)

I machined the mustang rotors using a rotary table on a vertical mill. I couldn't get the setup rigid enough to get a satisfactory result in reducing the diameter but I was able to get the hub dimensions machined. I then set up the rotors on my old Burke horizontal mill and got the diameter turned down. It was a ton of work getting an arbor fabricated and finding a cutter that worked well but it got done.

I think I would consider making a custom hub that would move the rotor to the outside so it can be swapped like more modern cars. It could also be made to accept a newer rotor that would be more available.

I just tried to fit up the rotors I machined and they will require a spacer of about 1/4" between the inner brain and the where the bearing seats against the spindle. I have not read about needing a spacer. Has anyone else run into this problem.?

dart swanger

Well-Known Member

Never had a problem using all the previous measurements that the guys layed out for me. No spacer was required but I did have to smooth out the outer part of the rotor hat to clear my rubber dust boots on my Kelsey Hayes calipers.

67 gt

A boy who loves his Mopars !

I had my hubs made with the 4.5 Stud Spacing had my rotors redrilled use all the factory kh setup ,STD bearings ,dust caps cost $300.00 no head aches been on the car for four years and no issues. I want to find rotors which will work in the future where I won’t have to drill. I thought 73 rotors might work but was getting different measurements from different sites . I know they are a little wider on the pad surface area and are a few mm taller but would clear inside the caliper . Just not sure of the hat area if it’s wider or shorter than the 67-71 models as the pictures are all generic.

Last edited:

here is a thought what if you take the factory center hub and fill in the 4 in lug holes to make it a solid non drilled hub and then redrill it to the 4 1/2 and tape it to use screw in studs then redrill the rotors this way you keep all oe parts in place it is something i have thinking of trying any inputs on this idea?

here is a thought what if you take the factory center hub and fill in the 4 in lug holes to make it a solid non drilled hub and then redrill it to the 4 1/2 and tape it to use screw in studs then redrill the rotors this way you keep all oe parts in place it is something i have thinking of trying any inputs on this idea?

I'm interested in this as well.

seems like a lot of expense and effort to go thru when guys like Dr Diff have good deals on swap kits using OE parts alreadyhere is a thought what if you take the factory center hub and fill in the 4 in lug holes to make it a solid non drilled hub and then redrill it to the 4 1/2 and tape it to use screw in studs then redrill the rotors this way you keep all oe parts in place it is something i have thinking of trying any inputs on this idea?

here is a thought what if you take the factory center hub and fill in the 4 in lug holes to make it a solid non drilled hub and then redrill it to the 4 1/2 and tape it to use screw in studs then redrill the rotors this way you keep all oe parts in place it is something i have thinking of trying any inputs on this idea?

That method is addressed in this thread. I don't remember where, but there are several negatives associated with it.

it may be i wish i could find it i have a set that was redrilled to the 4 1/2 by someone years a go i think if the 4 in holes are plugged with a solid plug it can be redrilled and then taped for screw in studs not press in then all the kelsey hayes parts can be reused if you dont have the parts then yes its more logical to install the 73 up brakes that widens the front wheel track that to me takes away from the look of the car that is just my opinion thanks for all the input

it may be i wish i could find it i have a set that was redrilled to the 4 1/2 by someone years a go i think if the 4 in holes are plugged with a solid plug it can be redrilled and then taped for screw in studs not press in then all the kelsey hayes parts can be reused if you dont have the parts then yes its more logical to install the 73 up brakes that widens the front wheel track that to me takes away from the look of the car that is just my opinion thanks for all the input

It can be done, but not easy, or folks wouldn't be re-machining Mustang rotors.

This link should take you to the post earlier in the thread where a member talks about why Moser isn't converting hubs anymore.

Using mustang rotors for 4.5" bc

Nope, didn't work.

Just go to post #12.

Just go to post #12.Hi! Just my 2 cents but here in France the main problem with our Mopars is that the shipping cost and customs fees are very high. So we had to find a way to put 4.5" on our A body. It happen that I am machinist and maybe 10 years ago I made a steel billet hub with 4.5" bolt pattern for my 68 Dart. It work perfectly... A few years later a friend from my national club: "Mopar Owner's Club" break a wheel adapter in the front of is 390 stroker Duster. All in all it was fine, just a bend fender... He ask me about my setup an long story short, we made around twenty paire of that hub for the club... If it can help ( the dimensions are metric... sorry) but the Mustang rotor seems to be a better option for you lucky American guys.

Attachments

Hi! Just my 2 cents but here in France the main problem with our Mopars is that the shipping cost and customs fees are very high. So we had to find a way to put 4.5" on our A body. It happen that I am machinist and maybe 10 years ago I made a steel billet hub with 4.5" bolt pattern for my 68 Dart. It work perfectly... A few years later a friend from my national club: "Mopar Owner's Club" break a wheel adapter in the front of is 390 stroker Duster. All in all it was fine, just a bend fender... He ask me about my setup an long story short, we made around twenty paire of that hub for the club... If it can help ( the dimensions are metric... sorry) but the Mustang rotor seems to be a better option for you lucky American guys.View attachment 1715533136

Hi,

So this hub will fit with original wheel bearings and BBP mopar rotors ?

DesertRat

Leading edge boomer

I did this conversion on my 67 with no issues. I got my machine shop to do what I asked and the install went smoothly. That was about 4/5 years ago and I drive the car daily.

If I was going to do another one I would by the later model big ball joint stuff though.

If I was going to do another one I would by the later model big ball joint stuff though.

YESHi,

So this hub will fit with original wheel bearings and BBP mopar rotors ?

I know it's an old thread, but does anyone know if there's anyone making these rotors and selling them? I'd buy a set!!

Dr diff dot comI know it's an old thread, but does anyone know if there's anyone making these rotors and selling them? I'd buy a set!!

I'm pretty sure Doctor Diff doesn't have these.

There's a shop I saw on Fakebook that sells these modified Ford rotors. They appear to be legit. I'll get their contact info and post it here.

There's a shop I saw on Fakebook that sells these modified Ford rotors. They appear to be legit. I'll get their contact info and post it here.

Thank you, I checked Dr diff website and didn't see anything I'd greatly appreciate the name of that shopI'm pretty sure Doctor Diff doesn't have these.

There's a shop I saw on Fakebook that sells these modified Ford rotors. They appear to be legit. I'll get their contact info and post it here.

e58duster75

Well-Known Member

Welcome from Oakwood Kennenniff,

I thought the same, and actually had them drilled for 4.5 BP just for mocking up wheels. If memory serves, the problem lies in the boss undulations on the back surface.Why couldn't the Mopar one be re-drilled with the larger pattern? seems like a lot less work than trying to find bearings and seals.

Chuck

-