As promised. "How To Mount A Tire"

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How To Change A Tire

- Thread starter RustyRatRod

- Start date

-

My apologies for the air compressor kicking in. Since what I was saying is important, here it is pretty much in a nutshell. I was talking about how important it is to lube the tire beads up so the beads will pop out properly on the wheel. You will notice a line or mark all the way around the sidewall down low very close to the wheel on both sides. This is a reference to assure the tire is properly seated on the wheel. If the mark or line is continuous and parallel to the wheel lip all the way around, it's popped out good. However, if you see the mark basically "disappear" under the wheel lip in a spot, that is an area where it is not popped out properly. I always let the air back out and break it back down and lube it up really good and air it back up and it will more than likely pop right out. Hope yall have enjoyed this.

Last edited:

Big_John

In my defense, I was left unsupervised.

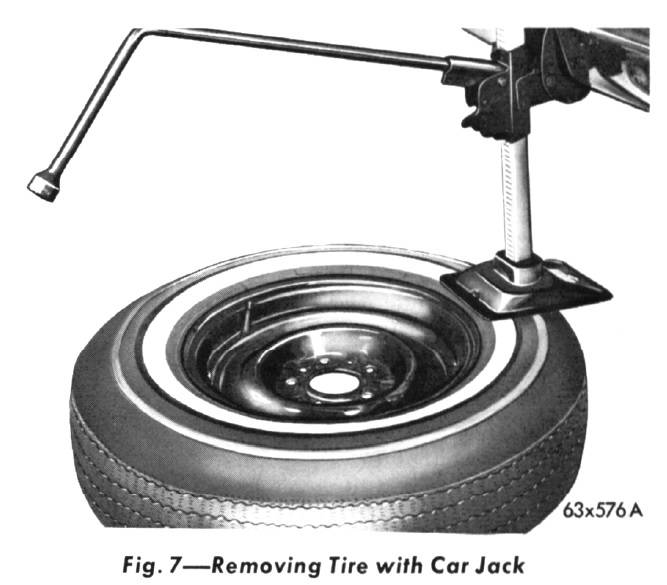

I like to use the method shown in the FSM for breaking the bead. In fact, I have a jack with a base that I use just for this. I use my truck to jack against rather than my Barracuda, but I have done this for many years now.

If you look at a jack base, you'll see that one face is arced to fit around a wheel.

If you look at a jack base, you'll see that one face is arced to fit around a wheel.

I like to use the method shown in the FSM for breaking the bead. In fact, I have a jack with a base that I use just for this. I use my truck to jack against rather than my Barracuda, but I have done this for many years now.

If you look at a jack base, you'll see that one face is arced to fit around a wheel.

View attachment 1715551881

That's pretty dangerous. At least it was for Daddy. I remember him trying that when I was a kid. The jack foot slipped off the sidewall and the top of the jack flipped down and hit him in the head. Took several stitches.

Big_John

In my defense, I was left unsupervised.

That's pretty dangerous. At least it was for Daddy. I remember him trying that when I was a kid. The jack foot slipped off the sidewall and the top of the jack flipped down and hit him in the head. Took several stitches.

Done it a bunch of times with zero issue. You have to have some common sense and keep the base in close to the wheel. I also don't squat down next to it either. My Dad always told me to keep my head out of the way.

Honestly, I don't know if I could use that big tire hammer with enough accuracy to call it "safe". Maybe you can, but I wouldn't be comfortable doing it.

pishta

I know I'm right....

yup, broke a few beads with the old jack base myself. The HF changer had a big lever with a curved foot to do the same. I had to bolt that thing the base of my pickup for it to work half decent, not designed to free stand to take any rotational torque. Maybe if you bolt it to a big pallet. I got it cheap with a coupon so it wasnt a terrible buy.

Dartnut

Don't hate me because i'm beautiful

Good videos, thanks for posting, Rob.

What do you do about balancing them after they are mounted?

What do you do about balancing them after they are mounted?

Mr. Sinister

Devastation Manager

Thanks Rusty its good to see a real working man posting his talent and its usefull.

Good videos, thanks for posting, Rob.

What do you do about balancing them after they are mounted?

Nothing yet. I am either going to go ahead and get a bubble balancer and do it myself, or just pay a friend to balance them. It rides very well. No vibration at all until about 70.

Done it a bunch of times with zero issue. You have to have some common sense and keep the base in close to the wheel. I also don't squat down next to it either. My Dad always told me to keep my head out of the way.

Honestly, I don't know if I could use that big tire hammer with enough accuracy to call it "safe". Maybe you can, but I wouldn't be comfortable doing it.

It takes practice, for sure. I changed tires for years so I have a lot of experience. That part where I said to find an old beat up wheel and tire....I wasn't kidding. I've changed some VERY high end wheels using a tire hammer and never scratched them. The biggest thing is keeping them well lubed......with "something".

pishta

I know I'm right....

IIRC Bridgstones (or another well known brand) had a dot on the tire that you line up with the valve stem for a good balance start. I think dynanic balance cannot be had with a bubble but it may not need it either.

It takes practice, for sure. I changed tires for years so I have a lot of experience. That part where I said to find an old beat up wheel and tire....I wasn't kidding. I've changed some VERY high end wheels using a tire hammer and never scratched them. The biggest thing is keeping them well lubed......with "something".

No one should ever call you lazy !

Do you bubble balance them too?

No one should ever call you lazy !

Do you bubble balance them too?

I used to have one, but my son "somehow" tore it up. I plan on getting another one, but for now, I'[m going to let a friend balance them. They actually ride pretty good.

IIRC Bridgstones (or another well known brand) had a dot on the tire that you line up with the valve stem for a good balance start. I think dynanic balance cannot be had with a bubble but it may not need it either.

They have two dots. A red one and a yellow one. The red one lines up with the lightest part of the wheel (normally the valve stem hole) and the yellow one lines up with the heaviest part of the wheel.

I change and balance my own tires also, started with sport bikes and buying tires online, only to hit various shops and they wouldn’t mount them unless you bought tires from them citing nonsensical liability, or they just wanted too much for the service (especially when your changing out tires every 2500-3000 miles!) So I made a bead breaker and a balancer and never looked back. Now I do my own car, van and truck tires as the cost has gotten ridiculous, not to mention I get tired of having to remind the newbie tire specialist that I want adhesive backed weights on the rims, or if they have the old fashioned hammer on weights to put them on the inside. Nothing worse than nice alloy rims with gouges all along the rim edge! Also, most shops don’t clean the rim bead area either or take the time to match up light and heavy marks, or maybe resort to popping the fresh mounted tires beads again and rotating the tire to try and get a balance using as little weights as possible. All things I learned doing m/c tires. I also use cut up milk cartons as rim edge protectors when leveraging the tire on. And, the Harvor Freight bubble balancer works just fine. Just have to have it setup solidly, take your time, and check your work multiple times to ensure you get repeatability.

I always preferred the bubble balancer over the hi tech stuff. Used one for years, never had a problem

Very poor mans way shown here, I just bolted a 2x4 (the arm or lever) to a shed wall stud and bolted a short piece of 2x4 (the piece that pushes on the tire) to the arm and viola! Bead breaker

View attachment 1715557470[/QUOTE

Lol love that!

Too all of those whose work stops, cause they don't have the right tool.

Improvise, adapt, and overcome. Boom!

Last edited:

-