pishta

I know I'm right....

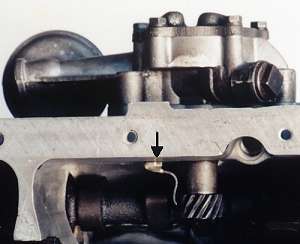

reading your Dutra oil mods article, it looks like my "drilled jet idea" wasn't exclusively mine after all..."One method is to simply drill a hole through the block’s main oil galley “pocket” and press in a small roll pin or tube with a .030 hole to direct a stream of oil directly onto the gears..." Why is the 6 bolt HV oil pump the only candidate: "...You will need a “6 hole” oil pump if you plan to do this modification and it takes some extra work but this ensures that lots of oil is placed on those gears, right where it is needed...."Does it only have the necessary pressure area to drive this?

So that whole article leaned toward too soft a gear and they said they hardened some but they didn't tell us if they worked. C'mon man!

So that whole article leaned toward too soft a gear and they said they hardened some but they didn't tell us if they worked. C'mon man!