How do you decide on which ratio to get?

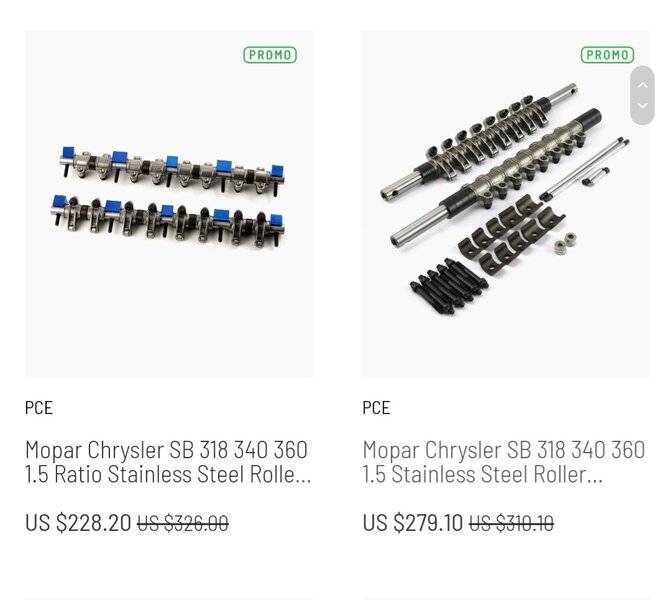

I didnt get any when I purchased my aluminum heads but now SM has all the SS rockers in stock ( well kinda...) so since they haven't had any in 7 months I think I may pick up a set... I kinda want 1.6 for a little "extra" lift from my cam but worry about valves hitting pistons?

Build...

30 over 340, pistons all around .012 out of the block

Xe268h camshaft

SM CNC fully assembled heads (pictured)

I know I know buy the expensive ones that are "better..."

I didnt get any when I purchased my aluminum heads but now SM has all the SS rockers in stock ( well kinda...) so since they haven't had any in 7 months I think I may pick up a set... I kinda want 1.6 for a little "extra" lift from my cam but worry about valves hitting pistons?

Build...

30 over 340, pistons all around .012 out of the block

Xe268h camshaft

SM CNC fully assembled heads (pictured)

I know I know buy the expensive ones that are "better..."

lol

lol