There was a lot of good W2 info on a sale thread.

Let's talk about them here instead.

Let's talk about them here instead.

Let's talk about them here instead.

Let's talk about them here instead.

Let's talk about them here instead.

Let's talk about them here instead.Did anybody cast the design in aluminum?Looks like a ported intake there.

IMO, they’re still a good head to consider with weight being the big draw back. It doesn’t take a ton of work to make them flow very well.

They’re about $650 a head, bare, new. While some complain and cry about having to equip the head with valves and gear, if your seriously building power, most aftermarket heads will need there pathetic springs replaced anyway.

I’d like to know how is doing what for valves other than the 3/8 valves.

I think one downside of the W2 is the reported propensity to crack. I don't know what percentage it affects, but I know it isn't an old wive's tale. I think it was fixed in the later castings? I know that I considered this when I had access to a set of early heads at a good price. I was hesitant to put all the porting work and bespoke parts into a part that had a chance of leaking. I still want a set and if I find the right vintage and configuration, I'll get them. That's another downside is knowing exactly what version you are getting. There are a lot of options and the PN's don't seem to be well defined on the heads.

You never will. As Bob said everything is stored in the barn and if your name is not Glidden, you are not getting in. This includes parts modified that didn’t work well. Even now that he has passed, I still doubt anyone will see them.Has anyone ever seen pics of the heads that Bob Glidden ran on his Arrow ? I remember he set a record the very first time he had the new car out ! Bob Glidden had to be one of the very best as he did almost everything himself with his family. I would really like to see what castings he used and what was done to them. I know there's his 351 Cleveland stuff still around to see, wonder what happened to the 340/W-2 stuff ?

Nice!So far I’ve been 9.70 at 137 @ 2880 lbs with my 362” W2 engine. Still more in it but I’m done chasing ET.

The W2 is tough to beat, I’ve run W2’s since 2009 and doubt I’ll run anything else. They simply make power. Can’t argue with the results.

I don’t care that W2’s are iron. Nonsense to even argue the aluminum vs iron debate. If you have both exhaust bolt patterns, LA headers fit and I’ve ran LA headers for many years. Been in the 9’s with LA headers bolted to W2 heads. The 2nd picture is LA headers and finally I built a set of W2 headers in the 3rd picture.

I don’t have fancy rockers, ductile iron rockers that see 7500 rpm all day long and never miss a beat. Been running these rockers for years.

Not much to complain about if you ask me.

View attachment 1716019536

View attachment 1716019537

View attachment 1716019538

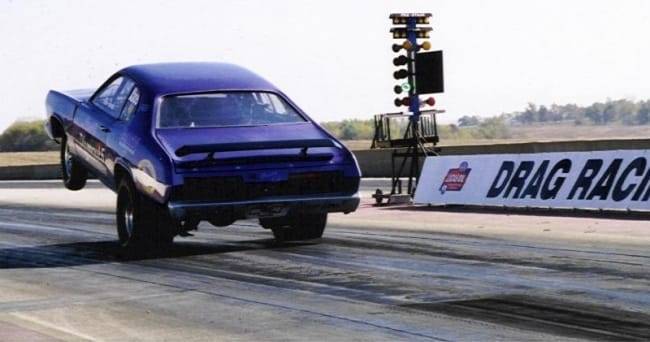

Ran 9.95 @ 135W2's work with alcohol too. And 318's. I just posted this in another thread. + .030 318, W2's, Enderle Injected/methanol, 5500 stall, Glide, 4.88's in a 9", 2750 with driver.

Good question. @pittsburghracer, have you ever messed with W2's?Does anyone know (no guessing) how close the Indy head is to the W2 in terms of short turn shape and size, minimum cross sectional area, and power potential?

I have no experience with either head in any form and would just like to know.

What was the rest of the combo? Cubes, cam, compression and gears?Glidden had W-2s on his Arrow but he basically re-engineered everything anyway to get the most out of it.

Heads worked well. I ran them on my Challengers through the '80's & '90's. Went a best of 10.22 @ 131 footbraking with the heads being ported with a Direct Connection porting template kit. weighing around 2,800 lbs w/driver. With what I know now and switching to a 904, I probably could have gotten it into the 9's without much trouble.

My opinion on their drawbacks are the extra expense of offset valve gear, especially when getting into offsetting and raising the shafts for longer stem valves. Exhaust adapters/headers also added to the costs over conventional heads.

Good question. @pittsburghracer, have you ever messed with W2's?

So far I’ve been 9.70 at 137 @ 2880 lbs with my 362” W2 engine. Still more in it but I’m done chasing ET.

The W2 is tough to beat, I’ve run W2’s since 2009 and doubt I’ll run anything else. They simply make power. Can’t argue with the results.

I don’t care that W2’s are iron. Nonsense to even argue the aluminum vs iron debate. If you have both exhaust bolt patterns, LA headers fit and I’ve ran LA headers for many years. Been in the 9’s with LA headers bolted to W2 heads. The 2nd picture is LA headers and finally I built a set of W2 headers in the 3rd picture.

I don’t have fancy rockers, ductile iron rockers that see 7500 rpm all day long and never miss a beat. Been running these rockers for years.

Not much to complain about if you ask me.

View attachment 1716019536

View attachment 1716019537

View attachment 1716019538

Mental hurdle…… that’s so true.There wasn’t (and isnt) a damned thing wrong with those ductile iron rockers. The only complaint I had was they weren’t available in 1.6 ratio.

They are virtually indestructible.

There has always been (at least years ago) many rocker choices for the W2. It wasn’t like you couldn’t get something.

Guys just have a mental hurdle getting over the offset rocker. Since I love horsepower I couldn’t care less about buying an offset rocker.

I agree, the mopar world would be a better place if the w2 had become commonplaceThere wasn’t (and isnt) a damned thing wrong with those ductile iron rockers. The only complaint I had was they weren’t available in 1.6 ratio.

They are virtually indestructible.

There has always been (at least years ago) many rocker choices for the W2. It wasn’t like you couldn’t get something.

Guys just have a mental hurdle getting over the offset rocker. Since I love horsepower I couldn’t care less about buying an offset rocker.

* Holley W-2 Strip Dominator intake w/2" 4-hole spacer0

What was the rest of the combo? Cubes, cam, compression and gears?

Yea, almost made it onto production on the "Little Red Express"I agree, the mopar world would be a better place if the w2 had become commonplace