Leanna, are those aluminum finned pieces in your pic sand blasted? How do you get the original look back?

I'm not real keen on revealing trade secrets, but in the interest of this being a DIY forum where we all learn from each other, I'll offer this.

Yes, they are media blasted. I do any necessary repairs (straightening, filing rough edges, etc.) immediately. Then, depending on how bad they are when I take them off the valve covers, they get blasted at anywhere from 40 to 80 psi.

I can restore your fins to either of the two factory finishes, fully polished or the 2-tone style (argent recesses with the remainder polished). Some customers choose; others decide to mimick what the factory did with theirs originally. Out of [I think] 28 sets of these valve covers that I've brought back to life, probably 3/4 of them had the 2-tone from the factory.

Although I have a 1 3/4 hp commercial buffer, I rarely use it on the fins in favor of hand-polishing each one individually ... it's honestly easier than spending hours trying to get the buffing compounds out of all those little crevices. (Also taken into consideration is the fact that powerful Baldor can fling a little piece of metal about five hundred yards if ya catch an edge wrong LOL)

I go through a

lot of sandpaper and wet-n-dry restoring a set of fins ... from 80 grit all the way through 2500. When all the polishing is done, I clear the fins so you don't have to worry about keeping them up in the future.

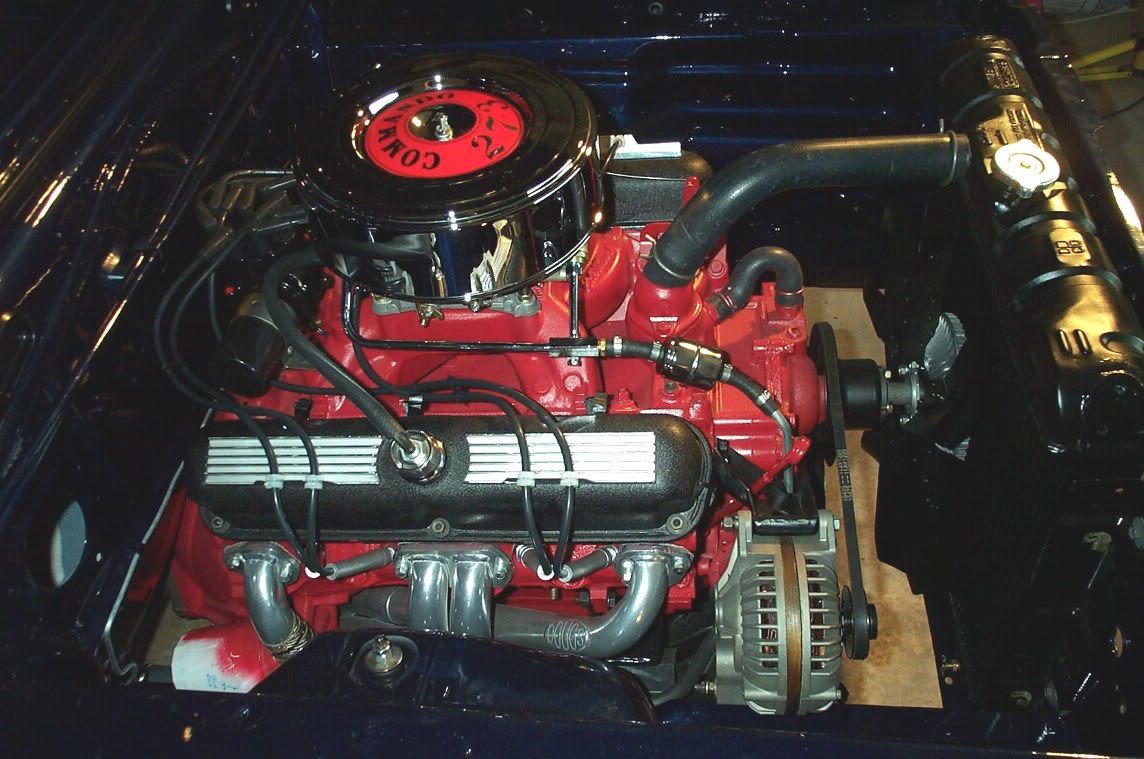

Considering these valve covers are around 45 years old and are pretty beat up by the time they get to me, it's easy to see that they're a TON of work. But the results speak for themselves.

Before ...

and After ...