My 360 Magnum build thread

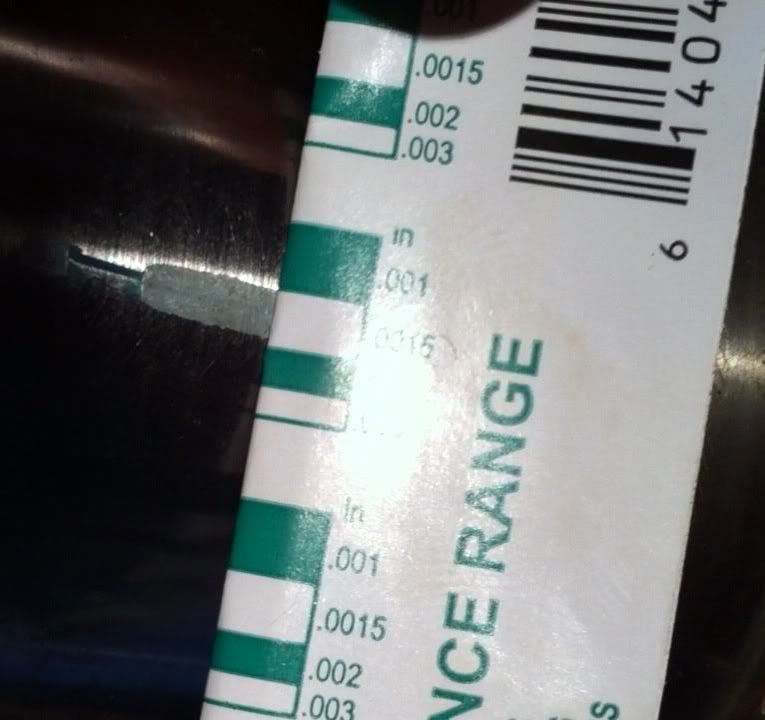

So I ordered some green plastigauge and checked clearances on all crank journals. Looked pretty good actually:

1 - .003

2 - .002

3 - .002

4 - .002

5 - .00175 ?

Here is a pic, as best as I could manage working alone trying to avoid the glare of the lamp

Here is the rear main cap, clearly thinner than the others...

If I'm reading my manual correctly, crank clearances are supposed to be between .0005 and .0020 - not sure if I should be concerned about the #1 cap being over .0020

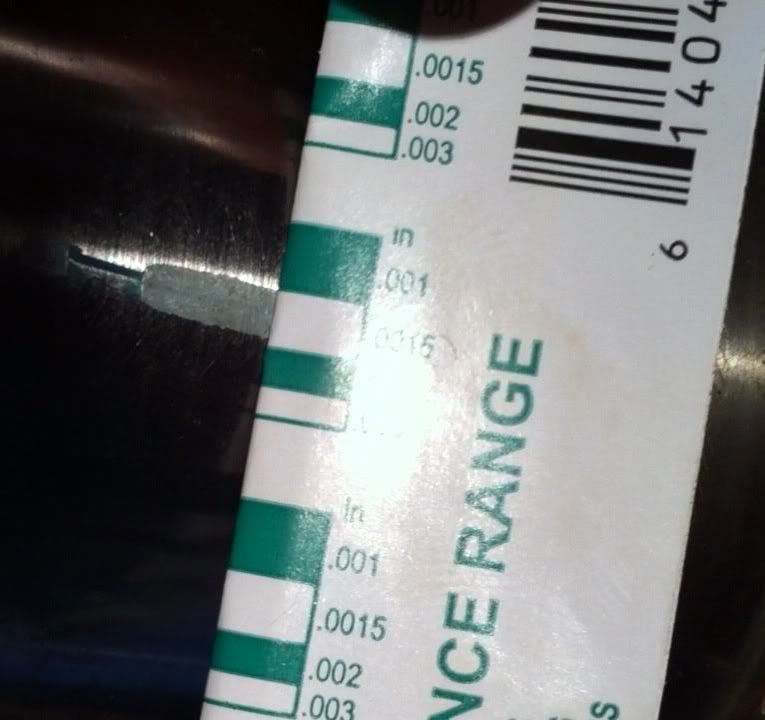

I also thought about checking clearances on all the rods but only got to one, here is how it looked

From my tech manual, rod clearance is supposed to be between .0005 and .0022 to - this rod looks to be right in the range

I made sure my torque wrench was correct and tightened all bolts to proper spec, according to my manual 85 lbs-ft for the mains and 45 lbs-ft for the rods, in 10 ft-lb increments.

After all clearances are checked and confirmed I will disassemble and debur all freeze/threaded plug holes and run a tap through all crank and head bolt threads; then a thorough cleaning and painting of the block before assembly.

I will need to make sure my main cap bolt holes are threaded all the way down so the milodon main studs fully engage, per their instructions, as I will be installing a windage tray.

So I ordered some green plastigauge and checked clearances on all crank journals. Looked pretty good actually:

1 - .003

2 - .002

3 - .002

4 - .002

5 - .00175 ?

Here is a pic, as best as I could manage working alone trying to avoid the glare of the lamp

Here is the rear main cap, clearly thinner than the others...

If I'm reading my manual correctly, crank clearances are supposed to be between .0005 and .0020 - not sure if I should be concerned about the #1 cap being over .0020

I also thought about checking clearances on all the rods but only got to one, here is how it looked

From my tech manual, rod clearance is supposed to be between .0005 and .0022 to - this rod looks to be right in the range

I made sure my torque wrench was correct and tightened all bolts to proper spec, according to my manual 85 lbs-ft for the mains and 45 lbs-ft for the rods, in 10 ft-lb increments.

After all clearances are checked and confirmed I will disassemble and debur all freeze/threaded plug holes and run a tap through all crank and head bolt threads; then a thorough cleaning and painting of the block before assembly.

I will need to make sure my main cap bolt holes are threaded all the way down so the milodon main studs fully engage, per their instructions, as I will be installing a windage tray.