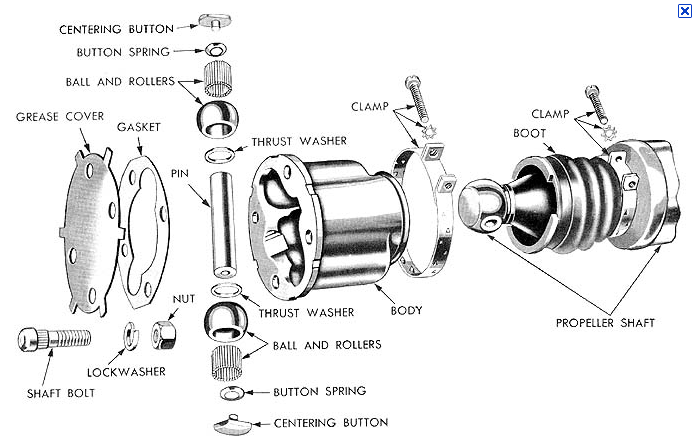

Original Balland trunnion u -joint

It's been a long time since I messed with a ball and trunnion setup. My recollection is....

Pry the cover off the end after prying up the tabs holding it on

You may have to remove the boot clamps to get enough room

Push the outer body down against the driveshaft

Now you should be able to remove any hardware and the balls

Then you'll have to "rig" necessary hardware to press the center pin out of the main part of the shaft

When installing a new pin it is IMPERITIVE that it be a tight press fit, and centered in the shaft with no more than .006" off center (from Motor's Manual.)

Modern wisdom is to take it to a driveshaft shop, and get the damn thing replaced with a modern U joint/ slip yoke setup

with a matching drive flange.

My God, I knew there was something seriously wrong, turns out that Rolls/ Bentley even used the damn things:

http://www.demascotte2.nl/werkplaatshandboeken/TSD2476-F-Drive Shafts and Universal Joints.pdf

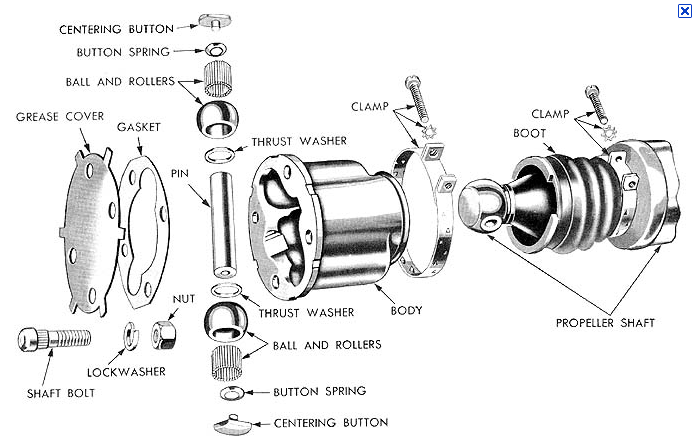

It's been a long time since I messed with a ball and trunnion setup. My recollection is....

Pry the cover off the end after prying up the tabs holding it on

You may have to remove the boot clamps to get enough room

Push the outer body down against the driveshaft

Now you should be able to remove any hardware and the balls

Then you'll have to "rig" necessary hardware to press the center pin out of the main part of the shaft

When installing a new pin it is IMPERITIVE that it be a tight press fit, and centered in the shaft with no more than .006" off center (from Motor's Manual.)

Modern wisdom is to take it to a driveshaft shop, and get the damn thing replaced with a modern U joint/ slip yoke setup

with a matching drive flange.

My God, I knew there was something seriously wrong, turns out that Rolls/ Bentley even used the damn things:

http://www.demascotte2.nl/werkplaatshandboeken/TSD2476-F-Drive Shafts and Universal Joints.pdf