70 duster: updating, and a no-dough pro-touring makeover

weekly update time.

short version:

the AC is almost finished. all i have to do is wire it, and get a cooling fan in it.

budget: add 13 for brackets, 38.17 for two pulleys and tow electric fans, 169 for an intake, 27 for paint, and 97.56 for a fuel pump block off plate, intake gaskets, and AN fittings, and 9.88 for a belt.

total: 4513.75

long version:

my wife and i were talking about what to do with the ac compressor situation. i shared with her my plans to go with a fabricated setup. i also shared my eventual plans for an intake swap, but that i really wasn't ready to spend the 279 for an eddy RPM air gap.

she wanted me to have a backup plan in case my fabbed setup didn't work out. so while looking on ebay, i stumbled across the pro-comp Chinese knockoff of the RPM air gap. really started debating it, and my wife said shed buy it for me if i agreed to take off the nitrous kit and give it back.

so i bought it, with a little bit of nervousness. these have had bot ends of the spectrum on reviews. from great, to serious porosity and core shift.

mine is actually better from a casting perspective than my victor Jr was. much cleaner and more consistent ports.

i was also surprised by the hardware they sent. instead of cheap freeze plug style things for the magnum pattern like i had heard about, i got stubby wheel stud looking plugs. knurled, with a nice domed top.

heres pics, with port pictures matched to fel-pro 1213 gaskets.

the manifold will get a little porting and cleanup before install, as well as a coat of blue paint. has to match.....

the 27 was for a quart of POR15 Chrysler blue. and i WILL have it shaken at the paint store before use this time.

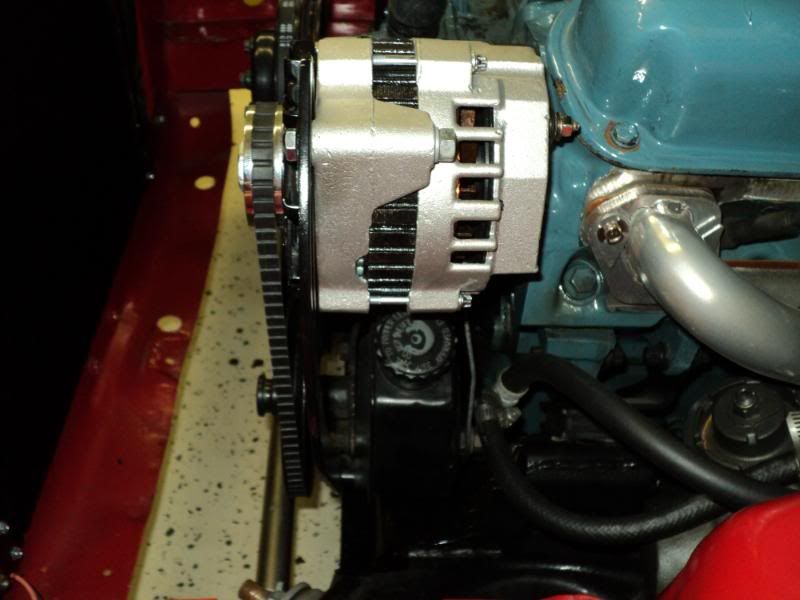

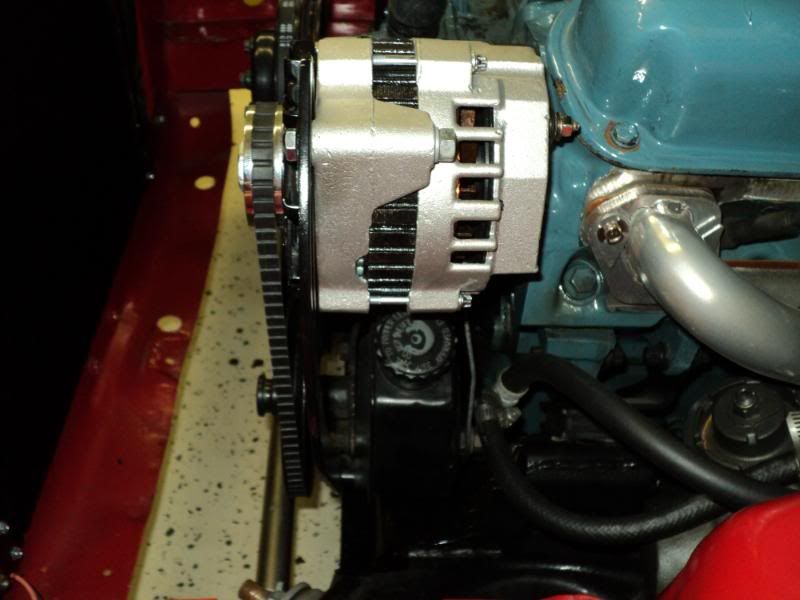

i also finished my accessory drive build. surprisingly, it all went according to plan, and a little better than i had hoped.

the most exotic things used in this accessory system, are, in order of oddity:

1. AC idler pulley and adjuster from a Honda D16Z6

2. heim joints and tube

other than that, it was all standard stuff.

for alternator support, i used a parts store Mr. Gasket alternator arm. by the way, the Taiwan chrome on those is CRAP. comes right off with a coarse scuffing pad on a zizz wheel

for all the spacers, i used some 1/2 ID steel tube that my dad had under the workbench. also used a little aluminum 3.8 fuel line for a couple of the spacers.

the major thing i had to find was AC/smog/PS pulleys. 4 groove crank, 2 groove water pump. got those for 8 each at pull-a-part this morning from an 85 new yorker that never went a mile without dripping oil. and the odo read 256,***. nasty, nasty car.

anyway, you can get the power steering dipstick out to check the fluid, too.

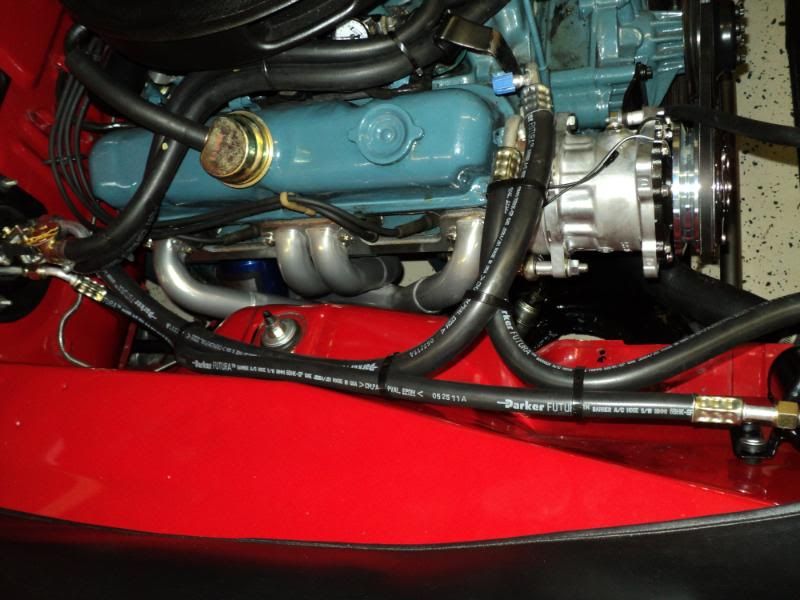

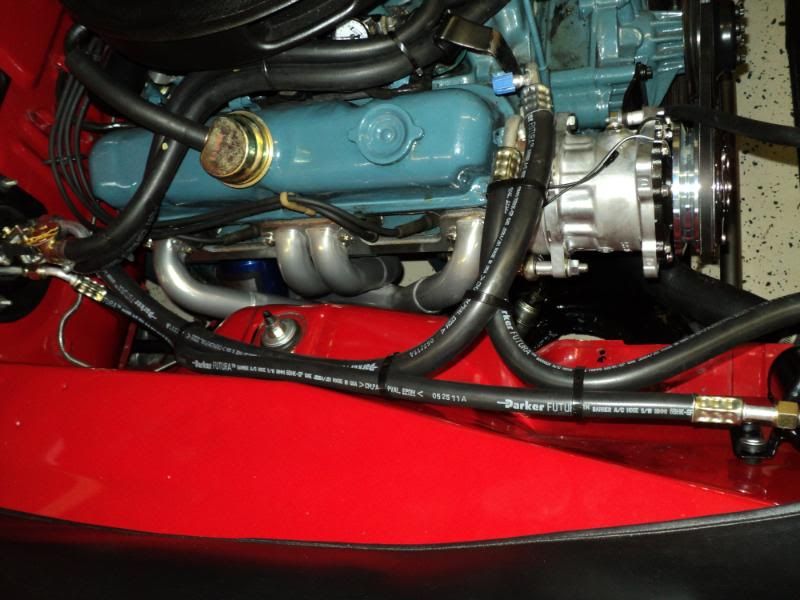

and then i got the lines in. i did change the location of where the rubber hose comes through the core support. classic air has it coming at the top of the core support, and it looked ugly. so i passed it through the same hole that the metal like comes through, and built a little aluminum plate to keep the two lines in place.

did not have to adjust any hose lengths. this is how they were delivered, just the routing has been changed considerably.

still have to find a cooling fan that fits. bought a set from a 2.7 dodge intrepid, but they are about .5 too deep and contact my water pump pulley.

the k-car fans i had on there, the motors contact my new accessory locations

i do still have this HUGE ford s-blade fan that i found one time. no lie, this thing is about 18 in in diameter. it was sitting on the hood of a crown vic at pull-a-part, and i bought it just because i had never seen an electric fan that size. heres to hoping it clears.

also have to do some wiring

fill the cooling system

finish my fuel pump regulator replumb and relocate

vacuum and charge the AC

add drivers side AC duct

hopefully ill get most of that knocked out tomorrow, so i can have it charged and cleaned up Wednesday on my day off. next weekend were supposed to meet up with our old group of friends from college, and id like to take the duster.

Michael

weekly update time.

short version:

the AC is almost finished. all i have to do is wire it, and get a cooling fan in it.

budget: add 13 for brackets, 38.17 for two pulleys and tow electric fans, 169 for an intake, 27 for paint, and 97.56 for a fuel pump block off plate, intake gaskets, and AN fittings, and 9.88 for a belt.

total: 4513.75

long version:

my wife and i were talking about what to do with the ac compressor situation. i shared with her my plans to go with a fabricated setup. i also shared my eventual plans for an intake swap, but that i really wasn't ready to spend the 279 for an eddy RPM air gap.

she wanted me to have a backup plan in case my fabbed setup didn't work out. so while looking on ebay, i stumbled across the pro-comp Chinese knockoff of the RPM air gap. really started debating it, and my wife said shed buy it for me if i agreed to take off the nitrous kit and give it back.

so i bought it, with a little bit of nervousness. these have had bot ends of the spectrum on reviews. from great, to serious porosity and core shift.

mine is actually better from a casting perspective than my victor Jr was. much cleaner and more consistent ports.

i was also surprised by the hardware they sent. instead of cheap freeze plug style things for the magnum pattern like i had heard about, i got stubby wheel stud looking plugs. knurled, with a nice domed top.

heres pics, with port pictures matched to fel-pro 1213 gaskets.

the manifold will get a little porting and cleanup before install, as well as a coat of blue paint. has to match.....

the 27 was for a quart of POR15 Chrysler blue. and i WILL have it shaken at the paint store before use this time.

i also finished my accessory drive build. surprisingly, it all went according to plan, and a little better than i had hoped.

the most exotic things used in this accessory system, are, in order of oddity:

1. AC idler pulley and adjuster from a Honda D16Z6

2. heim joints and tube

other than that, it was all standard stuff.

for alternator support, i used a parts store Mr. Gasket alternator arm. by the way, the Taiwan chrome on those is CRAP. comes right off with a coarse scuffing pad on a zizz wheel

for all the spacers, i used some 1/2 ID steel tube that my dad had under the workbench. also used a little aluminum 3.8 fuel line for a couple of the spacers.

the major thing i had to find was AC/smog/PS pulleys. 4 groove crank, 2 groove water pump. got those for 8 each at pull-a-part this morning from an 85 new yorker that never went a mile without dripping oil. and the odo read 256,***. nasty, nasty car.

anyway, you can get the power steering dipstick out to check the fluid, too.

and then i got the lines in. i did change the location of where the rubber hose comes through the core support. classic air has it coming at the top of the core support, and it looked ugly. so i passed it through the same hole that the metal like comes through, and built a little aluminum plate to keep the two lines in place.

did not have to adjust any hose lengths. this is how they were delivered, just the routing has been changed considerably.

still have to find a cooling fan that fits. bought a set from a 2.7 dodge intrepid, but they are about .5 too deep and contact my water pump pulley.

the k-car fans i had on there, the motors contact my new accessory locations

i do still have this HUGE ford s-blade fan that i found one time. no lie, this thing is about 18 in in diameter. it was sitting on the hood of a crown vic at pull-a-part, and i bought it just because i had never seen an electric fan that size. heres to hoping it clears.

also have to do some wiring

fill the cooling system

finish my fuel pump regulator replumb and relocate

vacuum and charge the AC

add drivers side AC duct

hopefully ill get most of that knocked out tomorrow, so i can have it charged and cleaned up Wednesday on my day off. next weekend were supposed to meet up with our old group of friends from college, and id like to take the duster.

Michael