no high pressure rv2 help!

I don't know where you are getting this "section of line." Again, there are only so many service ports on an automotive AC system. So far as I know, the only ones on the A bodies are on the compressor.

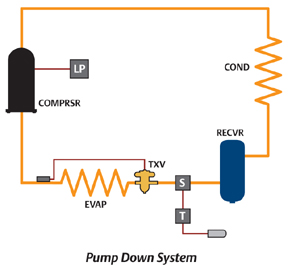

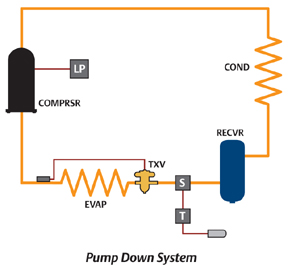

When the TXV is closed due to failure, this is essentially the same thing as "pumping down" a system. Some refrigeration systems use solenoids in the liquid line (the line between the receiver and the TXV)

When you close the liquid line, or in this case (assuming) the TXV is closed/ failed, you have NO HEAT LOAD in the system. That is, the evap is doing no work. The compressor attempts to "pull a vacuum" all the way from the "plug" IE solendoid valve or failed TXV, through the evap, through the suction line, and out the compressor, where the condenser, which again, HAS NO heat load, simply condenses the liquid in the condenser / receiver. Because the condenser is now "over" cooled, the liquid simply condenses and "sits there." (Known as "sub" cooled, IE below the saturation pressure/ temp.) Head pressure will start about normal on a "pump down" system, and as the pump down action continues, the head pressure, as well as suction, will fall to a fairly low value.

How a pump down system basically operates, and IF the TXV is bad, this is a direct comparison:

http://www.real-world-refrigeration.com/refrigeration-control-system-3.html

another:

http://www.achrnews.com/articles/quick-facts-migration-and-pump-down-systems

The diagram from the above page: Notice the solenoid valve between the receiver and TXV. What I'm trying to get across, here, is that essentially the same principles apply. A failed/ plugged TXV is essentially the same thing as a closed solenoid in a system with intentional pump down

Some systems use this as part of the control system. Typically, you have either a temperature control which senses box/ evap temp, or a pressure control on the evap. When the temp gets to the set point, or the evap pressure gets to the set point, the control shuts off the solenoid, shutting off liquid supply to the TXV. The compressor continues to run until it shuts off on a second low pressure switch.

I don't know where you are getting this "section of line." Again, there are only so many service ports on an automotive AC system. So far as I know, the only ones on the A bodies are on the compressor.

When the TXV is closed due to failure, this is essentially the same thing as "pumping down" a system. Some refrigeration systems use solenoids in the liquid line (the line between the receiver and the TXV)

When you close the liquid line, or in this case (assuming) the TXV is closed/ failed, you have NO HEAT LOAD in the system. That is, the evap is doing no work. The compressor attempts to "pull a vacuum" all the way from the "plug" IE solendoid valve or failed TXV, through the evap, through the suction line, and out the compressor, where the condenser, which again, HAS NO heat load, simply condenses the liquid in the condenser / receiver. Because the condenser is now "over" cooled, the liquid simply condenses and "sits there." (Known as "sub" cooled, IE below the saturation pressure/ temp.) Head pressure will start about normal on a "pump down" system, and as the pump down action continues, the head pressure, as well as suction, will fall to a fairly low value.

How a pump down system basically operates, and IF the TXV is bad, this is a direct comparison:

http://www.real-world-refrigeration.com/refrigeration-control-system-3.html

another:

http://www.achrnews.com/articles/quick-facts-migration-and-pump-down-systems

The diagram from the above page: Notice the solenoid valve between the receiver and TXV. What I'm trying to get across, here, is that essentially the same principles apply. A failed/ plugged TXV is essentially the same thing as a closed solenoid in a system with intentional pump down

Some systems use this as part of the control system. Typically, you have either a temperature control which senses box/ evap temp, or a pressure control on the evap. When the temp gets to the set point, or the evap pressure gets to the set point, the control shuts off the solenoid, shutting off liquid supply to the TXV. The compressor continues to run until it shuts off on a second low pressure switch.