<<<<<430 cube small block mopar build>>>>>

All washed and ready for assembly!

Got the pins & rings on - the pistons have wire locks - man i go them down by piston number 8 - lol

A little lube on the threads and bottom of the heads to achieve accurate torque

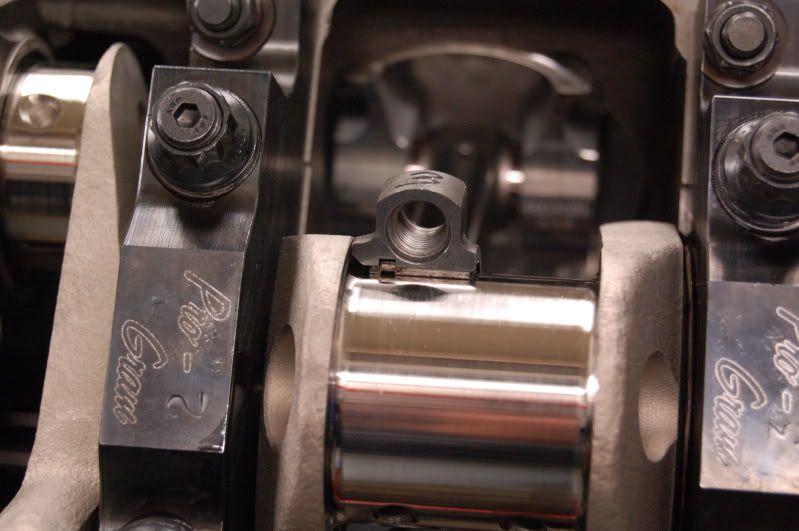

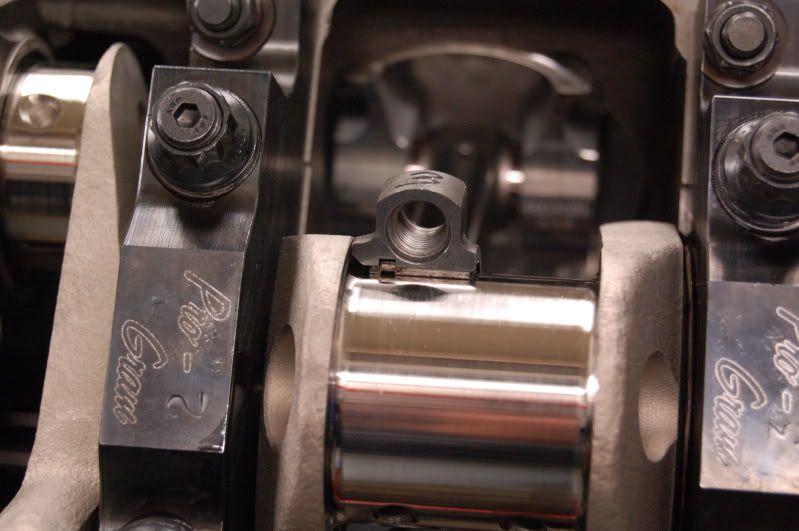

Sinking the pistons in and the chamfer goes to the crank side. you can also see the radius on the crank and the narrow bearing that misses the crank.

ARP's ring compressor made dropping the pistons in a breeze - it's tall enough to get the rings set in it at the bench and then drop it right in at the block with your thumbs.

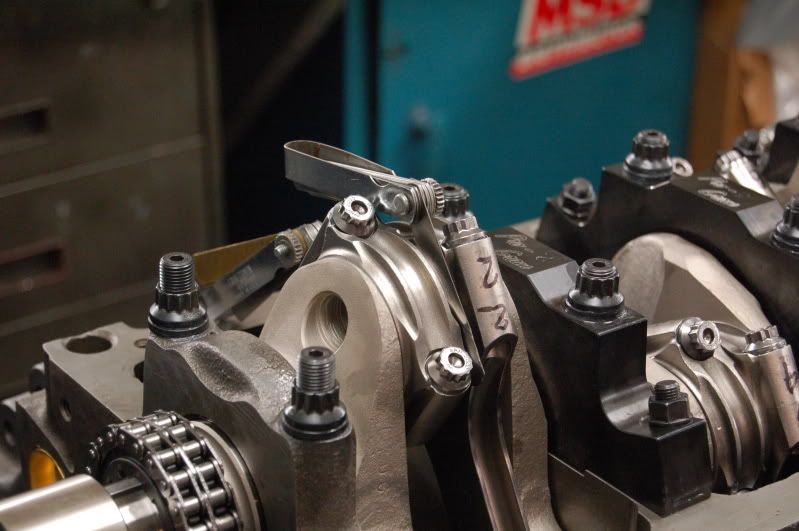

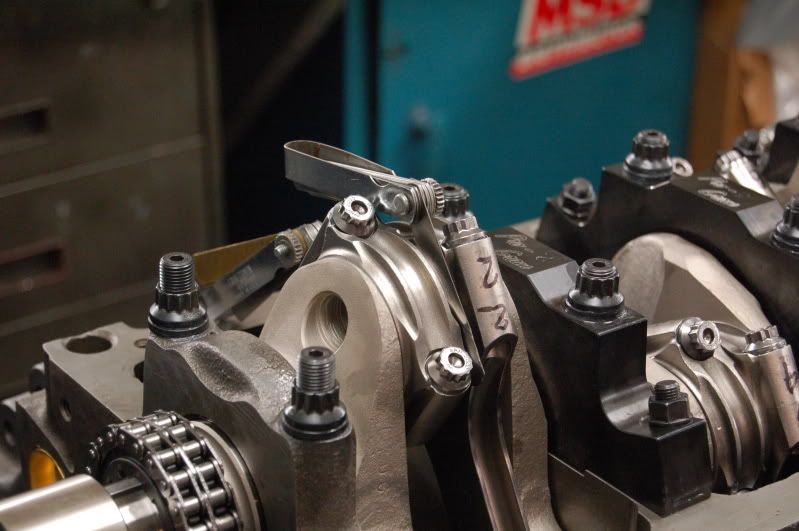

A couple feeler gauges set in between the rods keep everything square and true while torquing.

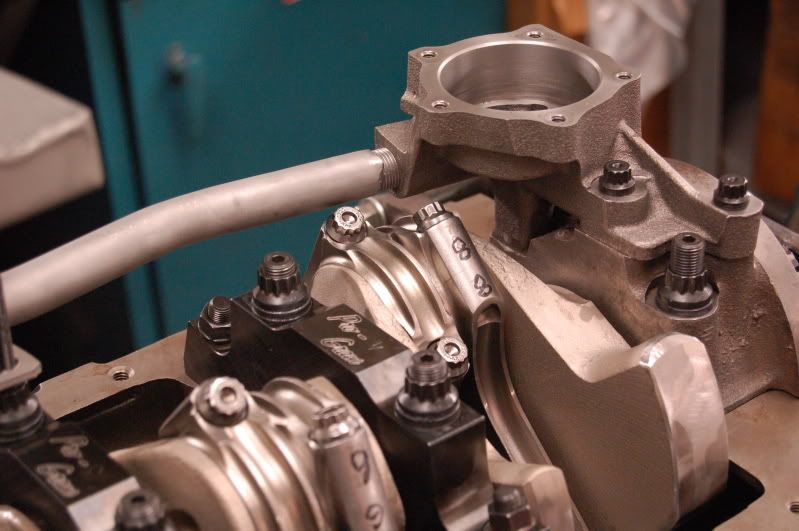

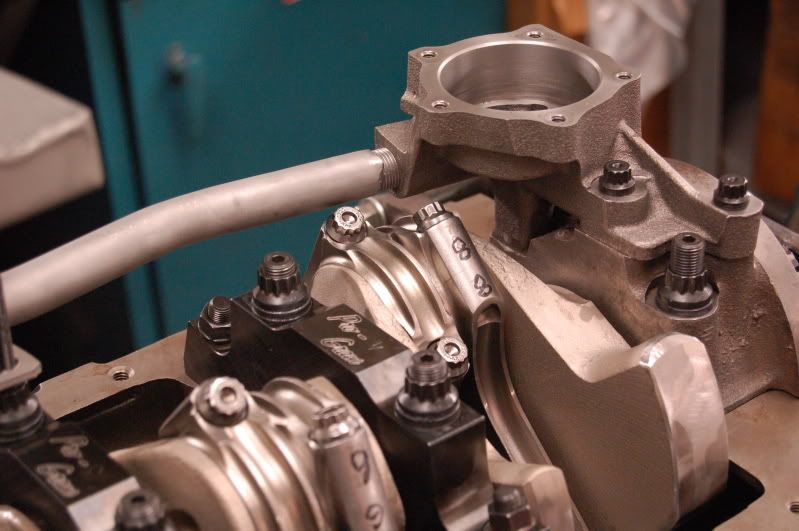

The 4.125" stroke and 2.00 inch rod journal make plenty of room where a stock mopar diameter rod would be into the pickup tube. I'd be curious of the 4.250 stroke in this area

Before checking the pan to pickup clearance - please look over and clean your pan - any weld spatter or dirt will get right into the engine.. ours had weld spatter, and took a bit to get it cleaned and free of these little buggers -

All washed and ready for assembly!

Got the pins & rings on - the pistons have wire locks - man i go them down by piston number 8 - lol

A little lube on the threads and bottom of the heads to achieve accurate torque

Sinking the pistons in and the chamfer goes to the crank side. you can also see the radius on the crank and the narrow bearing that misses the crank.

ARP's ring compressor made dropping the pistons in a breeze - it's tall enough to get the rings set in it at the bench and then drop it right in at the block with your thumbs.

A couple feeler gauges set in between the rods keep everything square and true while torquing.

The 4.125" stroke and 2.00 inch rod journal make plenty of room where a stock mopar diameter rod would be into the pickup tube. I'd be curious of the 4.250 stroke in this area

Before checking the pan to pickup clearance - please look over and clean your pan - any weld spatter or dirt will get right into the engine.. ours had weld spatter, and took a bit to get it cleaned and free of these little buggers -