"Rookie-Touring" '69 Dart

Well, I won't be back in December because I'm moving back the end of January. Updates won't be had until February or so. The prayer is I'll find a job before we move back and can more or less move to where the job is and get rolling. I keep hearing Nashville is hopping so I'm beginning to narrow my search criteria a bit.

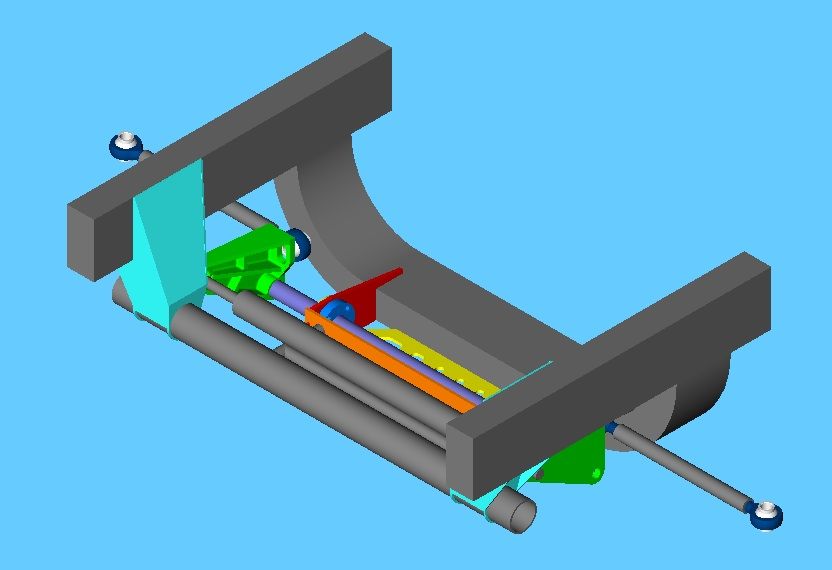

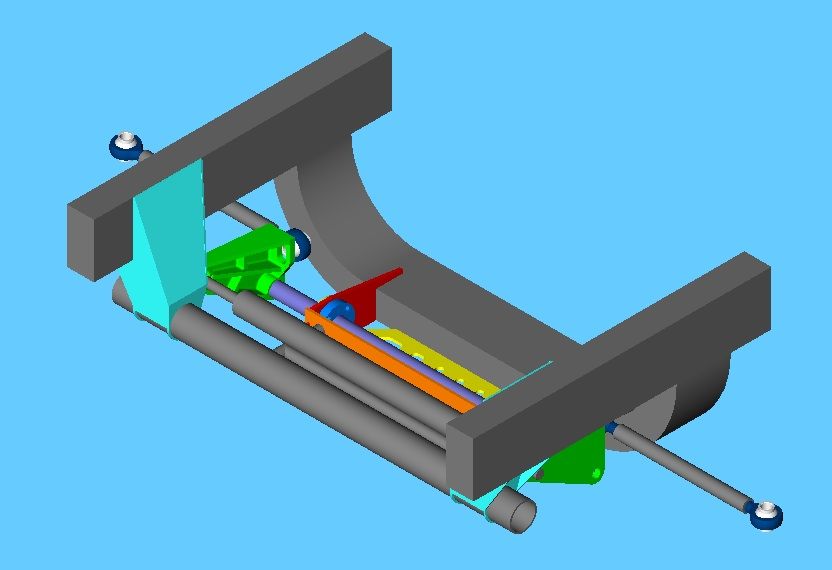

In the meantime, I've spent much of the year resolving my steering issues and planning my cooling system. The problem with my steering system is the engine is taking up space required by the steering rack, or visa-versa. The solution? A secondary steering slide, taken from an insane Ghia build that suffered the same problem. Below is a pic...

To summarize, the rack is mounted forward of the engine and connected to a 15-5 stainless shaft (purple) via two end brackets machined from 7075 (bright green). The shaft runs through a pair of Vespel bushings housed in a pair of inner (blue) & outer (can't see) hubs which sandwich the mounts (red). The mounts and upper (orange) & lower (yellow) support are all notched to be assembled off the car as quickly, and accurately as possible, then welded to the front cross-member as an assembly. Total assembly time should be minimal. All parts are out for machining now and will just be waiting for me to return. The rack itself will be mounted to a pair of tubes crossed in the shape of an X which run from the front/upper mount support (orange) forward to the sway bar cross tube. This cross tube attaches to the frame via mounts (light blue) that have been designed to be cut as 1-piece, then folded to shape and welded. That as well should go pretty quick. The only piece of the puzzle not already handled is the steering rack shaft needs to be replaced with one that is drilled and tapped in both ends rather than having a monoball end. Woodward isn't so helpful in this arena (not really outside the box thinkers there, IMO), so when I get everything setup I'll pull the shaft, take some detailed measurements, design a new shaft and have it machined from probably 15-5 stainless as well.

I've also been working on the cooling system planning and have designed a custom radiator which I'll be modeling in foam to verify fitment once the new tubular core support is assembled and mocked up, then I can have it built.

From there I need to do some more triangulation in key areas, reinforce some brackets, and weld, weld, weld. Then build a new oil pan, surge tank, and get this V10 brought to life. Then body panels and tin work, then test drive. Maybe test drive Flintstones style, then body panels and tin work...

I've picked up a bunch of tools and some parts as well. I mentioned in your thread Ross I just picked up the rest of my ISIS stuff, MiModHP stuff still being designed, Vintage Air has been bought, picked up a trailer hitch receiver to fab a hitch on the car (yeah, I'll be pulling my ski boat when all is said and done), some more pieces from a wrecked Viper, custom fr/rr sway bars from Speedway, flywheel, late model GTO back seat, and a bunch of piddly things to make building and fab much easier. No pics of all that because my photographer is getting worn out on all my "favors".

I am looking forward to getting back and getting some things done. Once I have all the triangulation, core support, etc. in place, I'm building my rotisserie to get all the finish welding done. So much to do, I can't wait to move on to fun things like wiring, interior work, custom fiberglass dash board, and all the other crazy ideas I have. I think I'm going to be building this thing forever... hahaha It'll be a great forever though!

Well, I won't be back in December because I'm moving back the end of January. Updates won't be had until February or so. The prayer is I'll find a job before we move back and can more or less move to where the job is and get rolling. I keep hearing Nashville is hopping so I'm beginning to narrow my search criteria a bit.

In the meantime, I've spent much of the year resolving my steering issues and planning my cooling system. The problem with my steering system is the engine is taking up space required by the steering rack, or visa-versa. The solution? A secondary steering slide, taken from an insane Ghia build that suffered the same problem. Below is a pic...

To summarize, the rack is mounted forward of the engine and connected to a 15-5 stainless shaft (purple) via two end brackets machined from 7075 (bright green). The shaft runs through a pair of Vespel bushings housed in a pair of inner (blue) & outer (can't see) hubs which sandwich the mounts (red). The mounts and upper (orange) & lower (yellow) support are all notched to be assembled off the car as quickly, and accurately as possible, then welded to the front cross-member as an assembly. Total assembly time should be minimal. All parts are out for machining now and will just be waiting for me to return. The rack itself will be mounted to a pair of tubes crossed in the shape of an X which run from the front/upper mount support (orange) forward to the sway bar cross tube. This cross tube attaches to the frame via mounts (light blue) that have been designed to be cut as 1-piece, then folded to shape and welded. That as well should go pretty quick. The only piece of the puzzle not already handled is the steering rack shaft needs to be replaced with one that is drilled and tapped in both ends rather than having a monoball end. Woodward isn't so helpful in this arena (not really outside the box thinkers there, IMO), so when I get everything setup I'll pull the shaft, take some detailed measurements, design a new shaft and have it machined from probably 15-5 stainless as well.

I've also been working on the cooling system planning and have designed a custom radiator which I'll be modeling in foam to verify fitment once the new tubular core support is assembled and mocked up, then I can have it built.

From there I need to do some more triangulation in key areas, reinforce some brackets, and weld, weld, weld. Then build a new oil pan, surge tank, and get this V10 brought to life. Then body panels and tin work, then test drive. Maybe test drive Flintstones style, then body panels and tin work...

I've picked up a bunch of tools and some parts as well. I mentioned in your thread Ross I just picked up the rest of my ISIS stuff, MiModHP stuff still being designed, Vintage Air has been bought, picked up a trailer hitch receiver to fab a hitch on the car (yeah, I'll be pulling my ski boat when all is said and done), some more pieces from a wrecked Viper, custom fr/rr sway bars from Speedway, flywheel, late model GTO back seat, and a bunch of piddly things to make building and fab much easier. No pics of all that because my photographer is getting worn out on all my "favors".

I am looking forward to getting back and getting some things done. Once I have all the triangulation, core support, etc. in place, I'm building my rotisserie to get all the finish welding done. So much to do, I can't wait to move on to fun things like wiring, interior work, custom fiberglass dash board, and all the other crazy ideas I have. I think I'm going to be building this thing forever... hahaha It'll be a great forever though!